Engineer / Quality Information

TECHNICAL INFO

TECHNICAL INFO

Features of Leimac Lighting Equipment

It can be collaborated with FA System Group.

Drawing does not flow outside because it is assembled and processed in our manufacture.

It is possible to utilize the know-how of electricity, mechatronics and program.

Also we can consider/design/manufacture the enrire inspection device.

We welcome a distributor or OEM requests.

There is no affiliation with a specific user/Purchase specific partners.

Reflected in the price reduction with reduced operating and administrative expenses.

-

We welcome the customized or new development design.

We have a laboratory of experiment of image processing.

Potential pursuit of the LED light source that is not limited to the field of image processing.

We perform the optical design originally

What is an Lighting Equipment?

A semiconductor device that emits light by running current

LIGHT

EMITTING

DIODE

Features of LED

There is (±) polarity.

Rated voltage / current is different depending on the element.

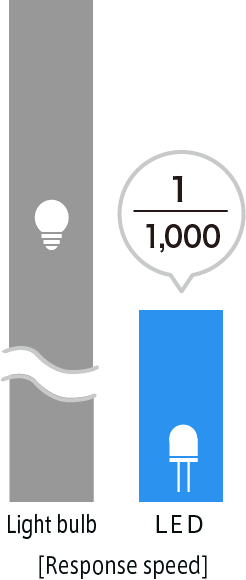

Response speed is very quick.

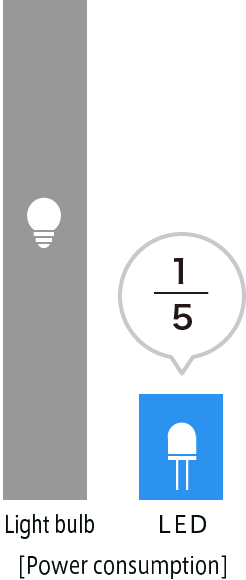

High efficiency = low power consumption

Long life (some brightness deterioration due to natural heat).

Resistant to switching.

Resistant to vibration and shock.

Element itself is waterproof.

Bullet type and chip type are common.

Many of LED has the directional light.

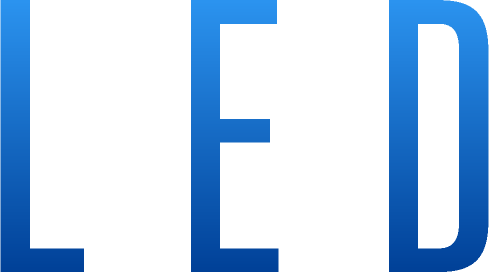

Lifetime※Values shown do not represent the estimated life of individual LED elements and are not garanteed.

Responsespeed

Power consumption

LED lifetime

Due to its very nature, an LED will not completely cease lighting up, unlike an incandescent lamp which will no longer light up once the filament wears out.

However, over time the LED’s light transmission rate will decrease and its light flux will degrade due to the degradation of the LED chip and the resin that seals the chip. Accordingly, the life of an LED is defined as the time it takes for LED luminance to decrease to 50% of initial luminance at an ambient temperature of 25°C; not the time it takes until the LED no longer lights up.

This definition of LED life also applies to LED lights with LED elements mounted.

The LED life time of required brightness is different depends on the customers from what percent of brightness is required compared to the initial. It may be said that it is the “past life”when it is 20% down from the initial brightness for those who think present brightness is just enough.

For the customers satisfied with 50% luminance of the light capacity in the initial stage, luminance decreased to 50% of the initial value may be considered to be still usable since required luminance can be maintained by increasing controller as the luminance decreases.

Accordingly, we cannot uniformly define the life of light.

LED Brightness

Green (555nm) is good most sensitive, the human eyes are opposite the green in applications such as visual inspection.

However, in the image processing, even lighting that looks bright visually, can be dark in the image of the camera. You also need to consider the compatibility of the illumination wavelength and peak sensitivity characteristics with the individual camera.

The image is brighter when illumination wavelength and peak sensitivity of the camera are close.

Selecting Lighting Equipment.

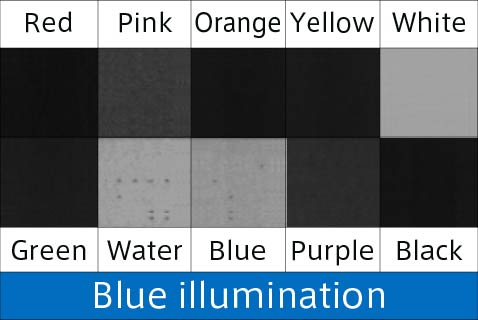

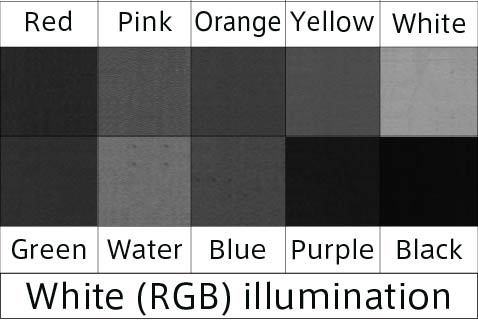

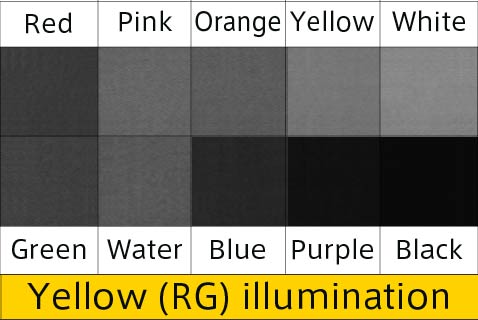

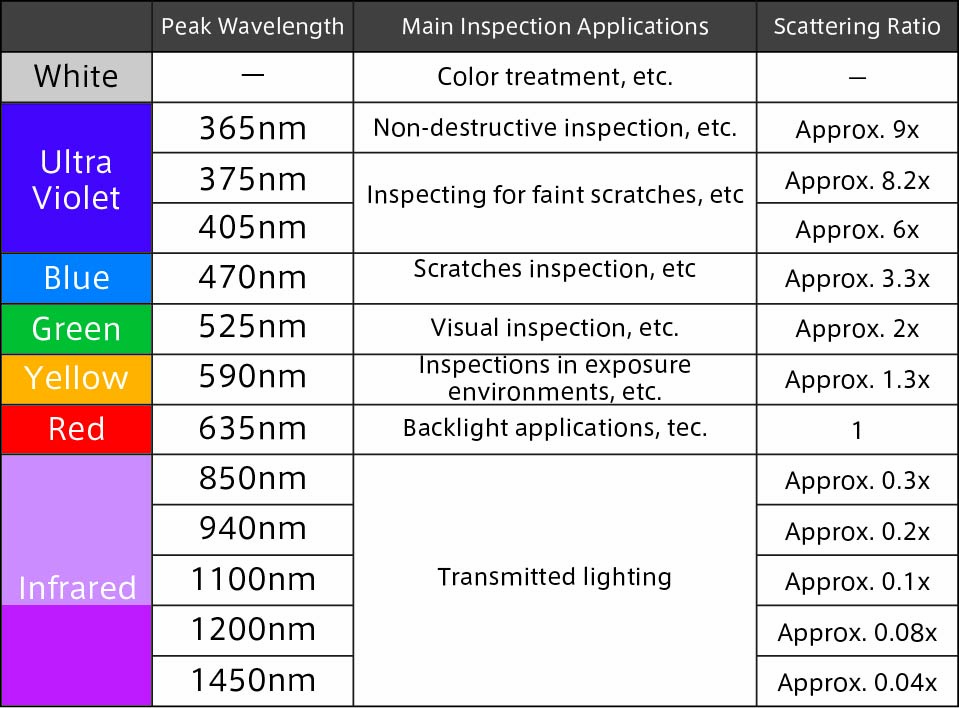

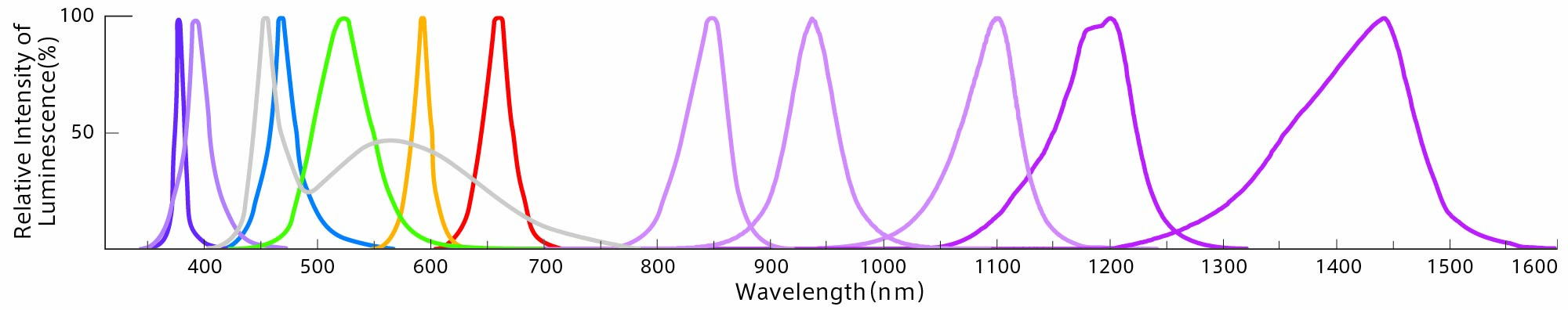

Selecting lighting by wavelength.

- Shorter wavelengths have larger scattering ratios, and are suited to surface inspection applications.

- The contrast will worsten when the object and lighting are the same color.

- We recommend selecting the low cost red lighting if it is not color processing.

※The scattering ratio is inversely proportional to the 4th power of wavelength.

※The scattering ratio is inversely proportional to the 4th power of wavelength.

※Described wavelength is for reference only. There are some LEDs which does not fit in the above cases.

Wavelength characteristics

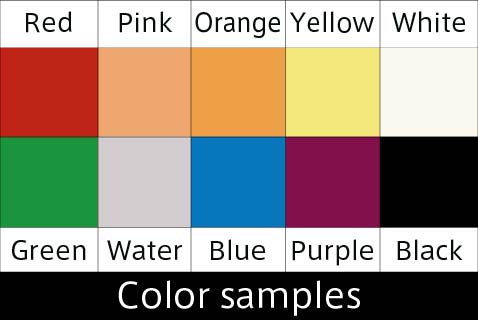

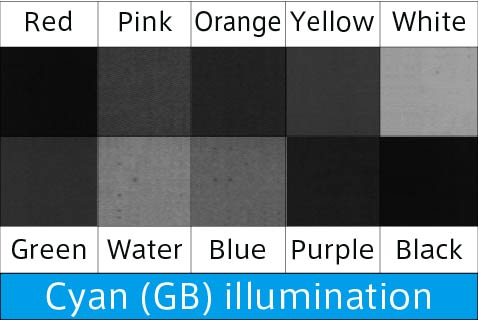

Comparison of Wavelength and objects

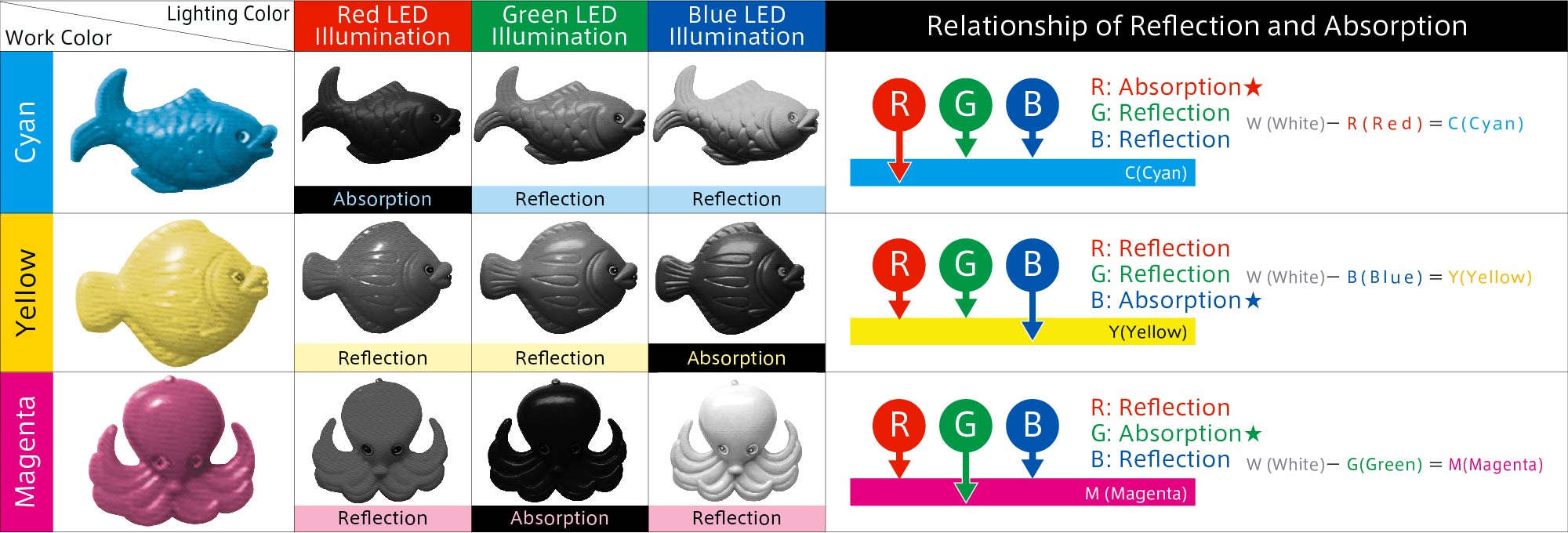

Whereas ordinary lighting is designed to make things brighter, in the field of image processing, lighting plays the key role of emphasizing only the areas of a subject that are of interest and capturing optimal images. Light bulb The color relationship between wavelength (lighting color) and objects, taking into account the relationships of typical complementary colors, is shown in the tables below.

※The above tables depict a typical example only and may not be applicable depending on work characteristics (reflection, transmission, and absorption), and camera and lens (optical system).

Reflection and absorption of color

The selection depends on the type of Lighting Equipment.

Direct LightingDirect Ring Light, Direct lighting bars

The LED elements are mounted in high density.

Most suitable when requreing high brightness.

IDR series

Direct Ring Light

General ring light for a diverse range of visual inspection.

-

IDBA series

Direct Bar Light

Used in everything from oblique to back lighting application. It is a direct-type surface-emitting lighting that implements a high density on a plane bullet-type LED elements.

-

Coaxial Light TypeCoaxial lighting

Light is irradiated coaxially with a camera using a half mirror.

Most suitable for the character recognition.

-

IFVA series

Narrow-angle light distribution coaxial Light

Ideal for objects with mirrored surfaces. It is the lighting that can be irradiated with same axis as the camera by using a half mirror.

-

Transmissive LightingSquare Edge-Light, Chip plane surface light

Uniform flat surface lighting

Most suitable for inspection of the profile with backlight.

-

IHMA series

High-intensity Chip LED Surface Light

Evolved high-intensity transmission illumination. A chip-type transmissive lighting solution that delivers high output at an affordable price in a lightweight package.

-

IDHM series

Chip LED Surface Light

Highly uniform, high-intensity thin-surface light

-

IFL series

Square Oblique Light

Thin, uniform, flat-surface lighting with low power consumption

-

Spot Light TypeCoaxial Spot Light

It substitutes for an optical fiber light guide.

Effective as a spot light.

-

IV-14・IV-30・IHV-20・IHVE-21 series

Coaxial Light

It is ideal for positioning (alignment) in industries such as liquid crystal, semiconductor and electronic components.

-

Indirect LightingShadow-less Ring Light, Dome Light

LED elements do not make shadow due to indirect lighting.

Suitable for glossy objects.

-

IPR series

Shadow-less Ring Light

Uniform illumination of objects with glossy/irregular surfaces. It is an indirect lighting that implement the LED around the ring-shaped light guide plate.

-

IDD-K series

Dome Light

Reflective type uniform dome irradiation. You will be presented with a uniform image with no halation and shadows.

-

Special LightingUltraviolet Light, RGB Full-color Light

Such as a three-color and infrared, ultraviolet and waterproof type.

Special purpose

-

Ultraviolet series

Ultraviolet Light

Allowing clearer inspection than visible light. We prepare wavelength of 365,375,405.

-

Infrared series

Infrared Light

Suitable for transmissive inspection of liquids, and print

-

RGB3-Color series

RGB Full-color Light

Blend lighting colors to suit the purpose of the inspection.

Selecting Controllers for Lighting Equipment.

Pulse Light Control System.

Controlling the brightness by changing the pulse width.

-

Advantage

- – When turning on, the light luminance is relatively uniform because it is unlikely affected by the fluctuation of Vf of the element.

- – It has a longer operating life than contumuous lighting using the voltage light control because it turns on/off at a high speed.

-

Disadvantage

- – A camera with an ultra high-speed shutter may get dark when it synchronizes with the shutter.

- – Noise is likely to occur.

Voltage Light Control System.

Controlling the brightness by changing the voltage.

-

Advantage

- – It is unlikely that a camera may get dark when it synchronizes with a shutter in the same way as with the puls light control controller.

-

Disadvantage

- – The light luminamce can not be unirom because the fluctuation of Vf of the element affacts significantly.

Controllers List

| Controller Type |

Controller Light Control System |

Light Control System |

External on/off Control |

External Light Control |

Input Voltage |

|---|---|---|---|---|---|

| ILP | PWM | Digital 1000 levels |

◯ | – | DC24V |

| ILC | Current | Analog (0~100%) |

◯ | ◯ | DC24V |

| ILV | Voltage | Analog (0~100%) |

◯ | ◯ | DC24V |

| ILS | Overdrive | Digital 256 levels |

◯ | ◯ | DC24V |

| IPPA-7M4G | PWM | Digital 256 levels |

◯ | ◯ | PoE Controller |

| IRPA_30M4G | PWM | Digital 256 levels |

◯ | ◯ | DC12V |

| IPSA | PWM | Digital 1000 levels |

– | ◯ | PoE Controller |

| IPPA | PWM | Digital 256 levels |

◯ | ◯ | PoE Controller |

| IDGB | PWM | Digital 256 levels |

◯ | ◯ | AC100~240V |

| IDGB-PG | PWM | Digital 256 levels |

◯ | ◯ | AC100~240V |

| IDPA | PWM | Analog (0~100%) |

◯ | – | AC100~240V |

| IDCA | Current | Digital 256 levels |

◯ | ◯ | AC100~240V |

| IMC | Current | Digital 1000 levels |

◯ | ◯ | AC100~240V |

| IWDV-24 | Voltage | Digital 1000 levels |

◯ | ◯ | AC100~240V |

| IWDV(S)-48 | Voltage | Digital 1000 levels |

◯ | ◯ | AC100~240V |

| IWDV(SL)-48 | Voltage | Analog (0~100%) |

◯ | ◯ | AC100~240V |

| ISC | Strobe | Digital 1000 levels |

◯ | ◯ | AC100~240V |

| IJS | Overdrive | Digital 256 levels |

– | ◯ | AC100~240V |

| IJS-30M2-TP/SS | Overdrive(Super strobe) | Digital 256 levels |

– | ◯ | AC100~240V |

| ILS-40M2-PI/SS | Overdrive(Super strobe) | Digital 256 levels |

– | ◯ | DC24V |

| SAG | Overdrive | Analog (0~100%)Digital 256 levels |

– | ◯ | AC100~240V |

Getting the most out of Lighting Equipment

Do not use Lighting Equipment in high-temperature environments as doing so will speed up the rate at which luminance decreases and elements degrade.

LEDs tend to decrease in luminance and undergo accelerated element deterioration due to heat (heat generated by the LED itself). While the typical half-brightness value of an LED element is said to be around about 30,000 hours, an LED element used continuously under high temperatures may degrade in a shorter time and decrease in luminance.

To mitigate loss of luminance and degradation due to heat.

-

Improve the heat dissipative ability of the Lighting Equipment unit.

It is recommended to install Lighting Equipment units in a structure or environment with good heat-dissipative capabilities, for example by taking steps to ensure adequate cooling.

Create air vents.

Attach a fan.

Attach the unit to a thick bracket or metal plate with good heat dissipative properties.

-

Turn lighting on and off in sync with image capture.

Lighting Equipment handles switching well.

Using the ability of Leimac light control controllers to turn lighting on and off via an external signal, it is possible to extend LED life by only turning them on when required. (Not all controllers come equipped with this function.) Reduce light modulation volume

When light is modulated with the volume down, the current flowing through the LED is lowered, and heat generation is suppressed.

Setting the camera aperture as large as possible when selecting lighting, will allow you to select a lighting unit with more than adequate brightness.

When using lighting continuously, it is recommended that light modulation volume is set to around 50%. (Even if luminance is reduced due to degradation, the volume can be increased to return to normal luminance.)

Lighting Equipment units should be moved as close to the subject as possible.

-

As LED elements themselves are small, Lighting Equipment units can be made compact and lightweight.

Illumination is inversely proportional to the square of the distance, so moving the lighting unit close significantly increases light intensity. (We also design lighting solutions to suit various applications.)

-

When using direct lighting,

Using a diffusing plate or polarizing plate can eliminate reflected lighting in some cases.

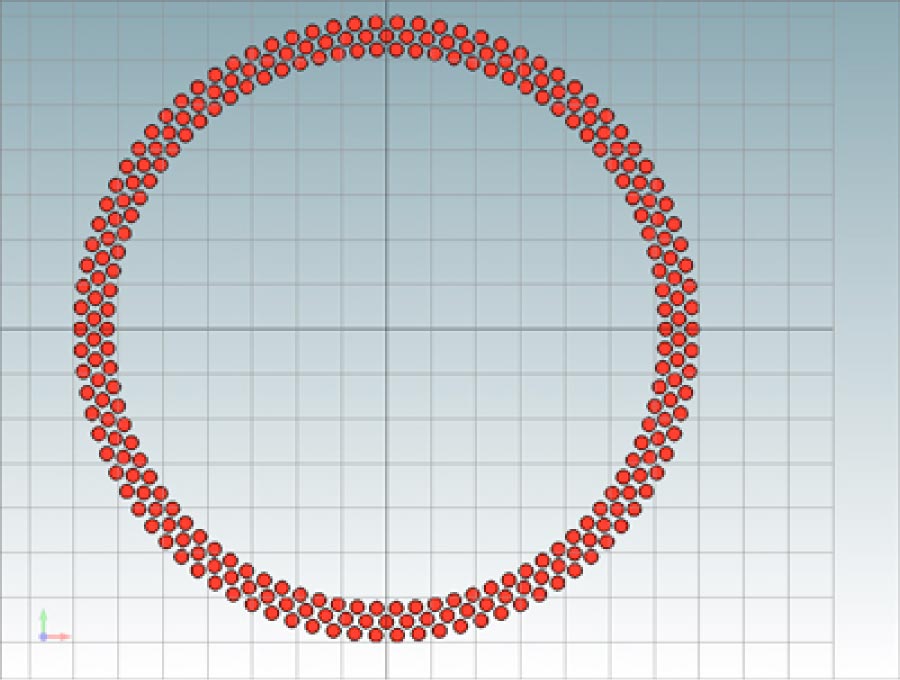

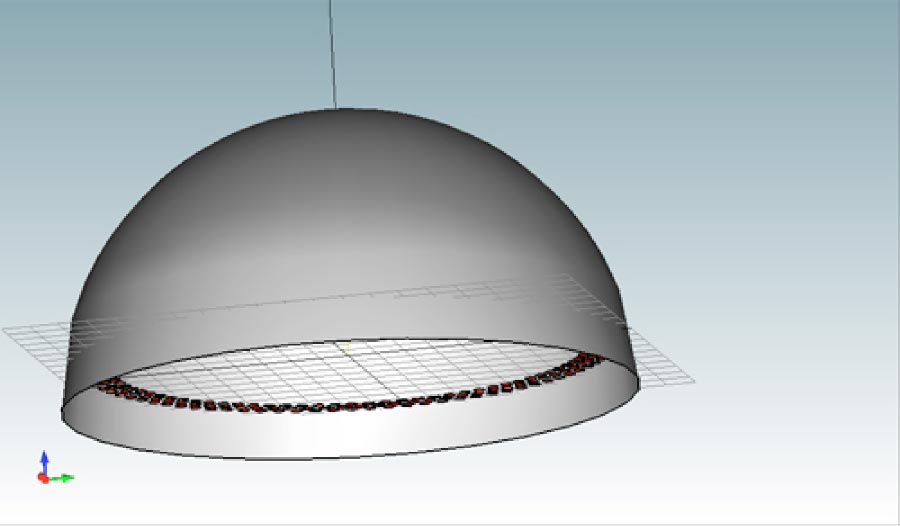

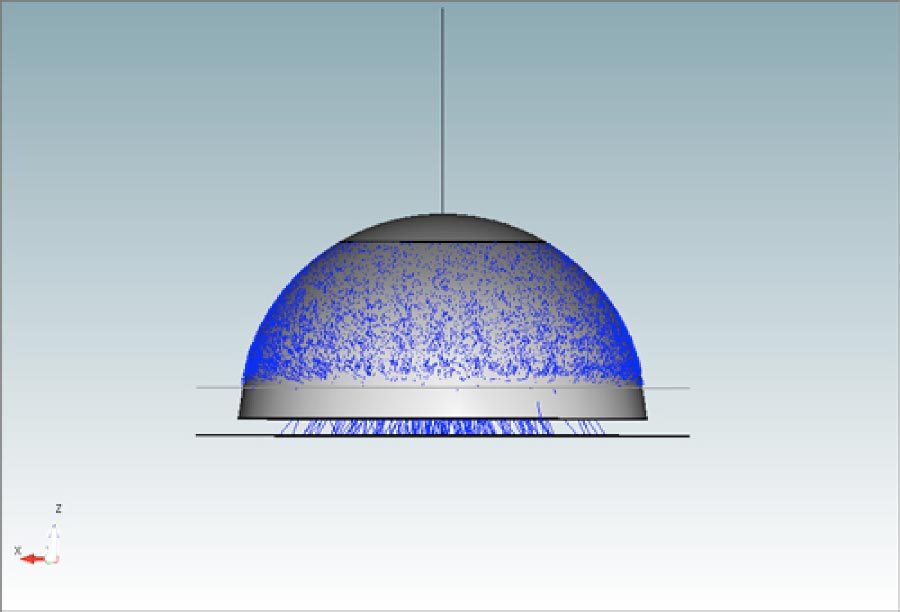

Lighting Simulation

We propose appropriate lighting without making a prototype through simple optical simulation.

· Custom / New development

· 3D design lighting etc.

Customized correspondence can be done from one unit.

-

Arrangement of light source (LED element)

Arrange the LEDs based on the design drawing.

-

Arrangement of peripheral parts

Place parts to be used.

-

Ray tracing

-

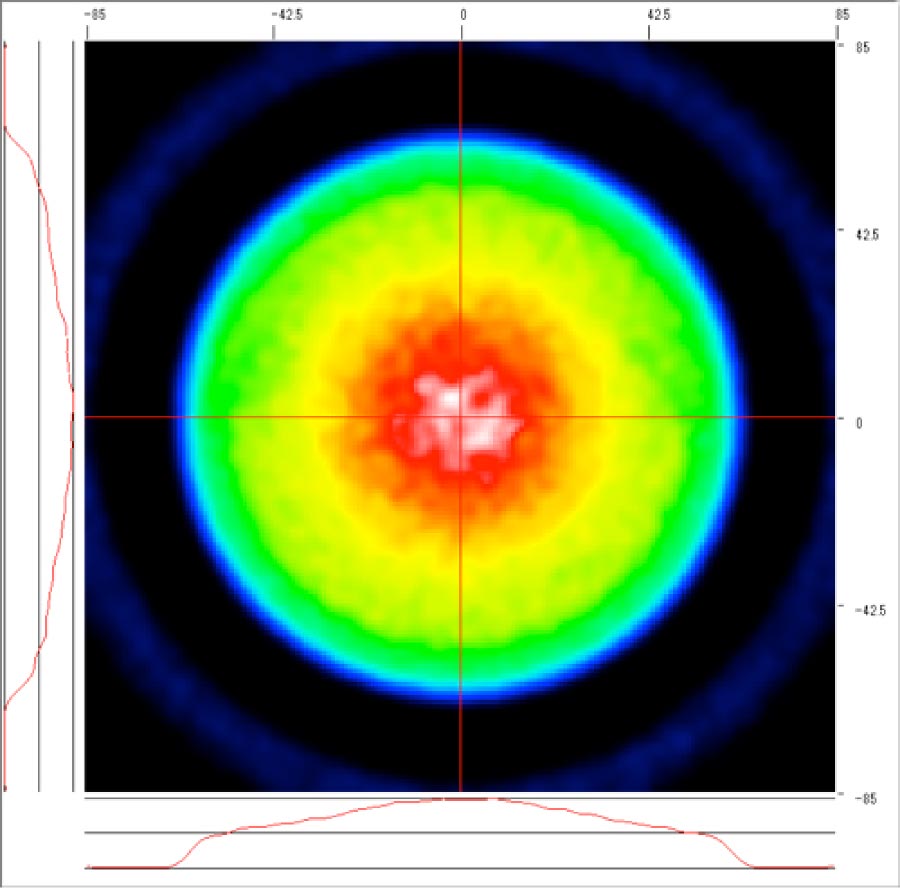

Simulation result

The distribution given by calculations is output as an image and a graph.

Quality Information

QUALITY INFO

Quality Assurance of Lighting Equipment

-

Warranty period

Warranty period:2 years after factory shipment*

In the event that an Leimac product malfunctions during the period stipulated above or in the event that the illumination output of lighting equipment decreases to 50%, Leimac shall repair the product free of charge or provide a replacement product as stipulated under Scope of Warranty. Consult Leimac and present the product in question.

*Warranty period for time to half-illumination-output shall be one year from factory shipment. -

Scope of Warranty

When used in accordance with the instruction manual under usage conditions specified by Leimac, in the event of a product malfunction within the warranty period, Leimac shall repair the product free of charge or provide a replacement product.

However, even if a claim is made within the warranty period, you will be charged in the following situations:

Malfunction or damage resulting from connecting the product to lighting equipment or a controller made by another company

Malfunction or damage resulting from incorrect usage or from improper repair, alteration, or disassembly

Malfunction or damage resulting from vibration, dropping, or other shock or from inappropriate handling

Malfunction or damage resulting from the occurrence of fire, pollution, riot, or a similar phenomenon or from external causes such as earthquake, lightning, flood, or other natural disasters or from use in a unique environment (abnormal voltage, high humidity, and the like).

Other cases in which liability is not attributable to Leimac.

-

Limitation of Liability

Secondary disasters (damage to equipment, lost opportunity, lost profit, and similar) incurred by the customer as a result of the malfunction of or damage to an Leimac product and any damages whatsoever shall not be subject to compensation.

-

Limitations of Warranty

This product warranty promises the aforementioned warranty details under the clearly indicated warranty period and conditions. Accordingly, it does not undertake any other guarantees, whether express or implied.

IMAC products are primarily designed for use with image processing and industrial inspection applications. This warranty shall not apply to use under circumstances like those outlined below:

Use in applications that may result in personal injury (nuclear power controls, railways, aviation, safety equipment) and particularly in applications that require reliability

Use in medical equipment that directly affects human life

Use in applications that have the potential to significantly affect property

Operating Environments of Lighting Equipment

-

[Lighting]

0〜+40℃

Ambient Temperature

35〜85%

Ambient Humidity

※No condensation

-

[Controllers]

0〜+40℃

Ambient Temperature

20〜70%

Ambient Humidity

※No condensation

-

[Cables]

0〜+40℃

Ambient Temperature

35〜70%

Ambient Humidity

※No condensation

*The above values are typical values and do not apply to all products.

Read the instruction manual carefully before use.

Usage Precautions of Lighting Equipment

Do not look directly at the light source.

Do not disassemble or remodel the light or controller unit.

Do not operate the product with wet hands.

Do not use products that are not suitable for an environment with high temperature, high humidity and splash.

Do not install the product in a dusty place.

Take appropriate measures for heat dissipation, cooling, and similar.

Install the lighting near the object as close as possible.

Try to use the light at minimum output or in flashing mode as much as possible.

Do not use a controller unit made by another company to power Leimac lighting products.

Make sure that all lighting and controller units comply with input voltage requirements.

Make sure that the controller capacity is larger than the lighting power consumption.

Do not use AC input from a controller that is used for motive power, solenoid valves, or similar applications.

Be careful of surges and electrical noise in the vicinity of the installation site.

Lighting and controller units may generate electrical noise.

Be sure to ground controller units that have a grounding terminal.

Be sure to follow the instructions on the screw depth instruction label when installing a lighting unit.

Environment of Lighting Equipment

Environmental policy

We contribute to the society as a research and development company, and construct an environment management system based on the policy below.

As the origin of “Manufacturing,” we engage in the continuous improvment of minimizing the burden on the global environment, the social responsibilities.

As creative challenge to the “Manufacturing,” we are trying to produce products that enrich the global environment.

We comply the legal regulation and agreement with region.

We engage in the issues below as an environmental preservation activity.

- – Improvement of environmental problems, and development and recommended sales of long-life products.

- – Reduction of waste

- – Enhancing energy‐saving awareness and its implementation

- – We contribute to “our customers’ ” reduction of waste and saving energy, including packing and distribution.

-

In order to implement and continue this environmental policy, we engage in making all employees, suppliers and contractors aware of the policy. Moreover, we make it public and raise their awareness of environment.

Revised RoHS directive compliant (2011/65/EU+(EU)2015/863)

As a restriction on the use of chemical substances related to the supply of environmentally friendly products, the revised RoHS Directive(2011/65/EU), which originally restricted the use of 6 hazardous substances such as lead, has been expanded to restrict 10 substances by adding 4 phthalates stipulated in Addendum (EU)2015/863.

(The LED lighting, controllers, etc., of our company, Leimac, are compliant as of July 22, 2021 as they are categorized as monitoring and control equipment.)

Most of our products have met the threshold of the original 6 hazardous substances in the revised RoHS Directive from April 2007, and have begun to meet the 10-substance threshold, which includes the 4 additional substances, as of July 2021(exemptions apply) for most standard products listed in the catalog.

For the revised RoHS directive compliance status of each product, please confirm the RoHS2 marking in the standards section on the individual product page on our website or contact one of our sales representatives.

RoHS2 Mark

|

Within the RoHS2 threshold of the 10 restricted substances (exemptions apply) |

|---|

6 restricted substances listed in the revised RoHS directive (2011/65/EU)

| Lead | Not exceeding 1000ppm |

|---|---|

| Mercury | Not exceeding 1000ppm |

| Cadmium | Not exceeding 100ppm |

| Hexavalent chromium | Not exceeding 1000ppm |

| Polybrominated biphenyls (PBB) | Not exceeding 1000ppm |

| Polybrominated diphenyl ethers (PBDE) | Not exceeding 1000ppm |

* Excluding exemptions

4 restricted substances as listed in additional items (EU)2015/863

| Bis(2-ethylhexyl) phthalate (DEHP) | Not exceeding 1000ppm |

|---|---|

| Butyl benzyl phthalate (BBP) | Not exceeding 1000ppm |

| Dibutyl phthalate (DBP) | Not exceeding 1000ppm |

| Diisobutyl phthalate (DIBP) | Not exceeding 1000ppm |

* Excluding exemptions

Corresponding to Chinese version RoHS Directive.

Chinese version RoHS Directive means “Measures for the Administration of the Restricted Use of the Hazardous Substances Contained in Electrical and Electronic Products”, implemented in China on May 1st of 2007. As well as RoHS Directive implemented in Europe, Chinese version RoHS Directive restricts the following 6 substances: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). The directive obligates manufacturers and traders in China to show content information of the 6 substances in electronic information products. Content information of our products differs depending on products. Please check hazardous substance usage restriction marks in each page about products.

Restriction mark of use of harmful substance

|

It does not contain target substances |

|---|---|

|

It contains target substances※ The figures mean expiry date of environmental protection |

Table1

Names of harmful substance and their content

| Restriction mark of use of harmful substance | Names of harmful substance | |||||

|---|---|---|---|---|---|---|

| Lead | Mercury | Cadmium | Hexavalent | Polybrominated biphenyl (PBB) |

Polybrominated diphencyl (PBDE) |

|

|

〇 | 〇 | 〇 | 〇 | 〇 | 〇 |

|

(This table is made based on the provision of SJ / T 11364.) |

||||||

| 有害物质限制的标志 | 有害物质的名称 | |||||

|---|---|---|---|---|---|---|

| 铅 | 汞 | 镉 | 六价铬 | 多溴联苯 (PBB) |

多溴二苯醚 (PBDE) |

|

|

〇 | 〇 | 〇 | 〇 | 〇 | 〇 |

|

(本表格依据SJ / T11364的规定编制。) |

||||||

Table2

Presentation of names and content of hazardous substances by part name: Switching controller are included.

IDGC series・IPPA series・IDCA series・IMC series・IWDV-24 series・IWDV-48 series・IJS series・SAG series

| Restriction mark of use of harmful substance | Names of parts | Names of harmful substance | |||||

|---|---|---|---|---|---|---|---|

| Lead | Mercury | Cadmium | Hexavalent chromium | Polybrominated biphenyls (PBB) |

Polybrominated diphenyl ethers (PBDE) |

||

|

Printed circuit board | × | 〇 | 〇 | 〇 | 〇 | 〇 |

| Case body | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Power supply | × | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Etc (cables and so on…) | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

|

(This table is made based on the provision of SJ / T 11364.) |

|||||||

| 有害物质限制的标志 | 部件名称 | 有害物质的名称 | |||||

|---|---|---|---|---|---|---|---|

| 铅 | 汞 | 镉 | 六价铬 | 多溴联苯 (PBB) | 多溴二苯醚 (PBDE) | ||

|

印刷基板 | × | 〇 | 〇 | 〇 | 〇 | 〇 |

| 框架 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 电源 | × | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 其他(电缆等) | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

|

(本表格依据SJ / T11364的规定编制。) |

|||||||

Table3

Presentation of names and content of hazardous substances by part name: Switching controller are not included.

ILP series・IDMU series・IPPA series・IRPA series・ILC series・ILC-24 series・IRC series・IRC-24 series・ILV series・ILS series・IPSA series

| Restriction mark of use of harmful substance | Names of parts | Names of harmful substance | |||||

|---|---|---|---|---|---|---|---|

| Lead | Mercury | Cadmium | Hexavalent chromium | Polybrominated biphenyls (PBB) |

Polybrominated diphenyl ethers (PBDE) |

||

|

Printed circuit board | × | 〇 | 〇 | 〇 | 〇 | 〇 |

| Case body | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Etc (cables and so on…) | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

|

(This table is made based on the provision of SJ / T 11364.) |

|||||||

| 有害物质限制的标志 | 部件名称 | 有害物质的名称 | |||||

|---|---|---|---|---|---|---|---|

| 铅 | 汞 | 镉 | 六价铬 | 多溴联苯 (PBB) | 多溴二苯醚 (PBDE) | ||

|

印刷基板 | × | 〇 | 〇 | 〇 | 〇 | 〇 |

| 框架 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 其他(电缆等) | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

|

(本表格依据SJ / T11364的规定编制。) |

|||||||

Compliance with the U.S. Toxic Substance Control Act (TSCA)

Our measures against products containing substances subject to the U.S. Toxic Substance Control Act (TSCA) is as follows.

In some of our products, we have confirmed the use of controllers equipped with film capacitors with sealing resins containing PIP (3:1).

If the product is to be distributed to regions where the U.S. Toxic Substances Control Act (TSCA) is applicable before the switch, please refer to the Notification PDF and take note of our notice to downstream suppliers “Regulation Section §751.407, PIP(3:1)(e)”. Please contact our sales department individually for the switching status of our products.

Applicable Products

Our standard, custom, and OEM light controllers equipped with components containing the sealing resins at issue.

(For details, please refer to the PDF attachment for the target models.)

Contents

| Contents | |

|---|---|

| Substances included |

PIP(3:1) phenol, isopropylated phosphate (Also known as tris(4-isopropylphenyl) phosphate) (CASRN 68937-41-7) |

| Target parts and parts contained |

Target parts: AC/DC switching controller film capacitor Target part: Urethane resin for sealing |

| TSCA Regulations |

“After January 6, 2025, all persons are prohibited from the processing and distributing in commerce of PIP (3:1) for use in adhesives and sealants, PIP (3:1)-containing products for use in adhesives and sealants, and PIP (3:1)-containing adhesives and sealants” cited from § 751.407 PIP (3:1)a.2.i. |

| Applicable Models |

Notification PDF Attachment Applicable Models |

About standard

About CE Marking

Lighting Equipment is included in the scope of application for the IEC 62471 standard, “Standard Regarding Photobiological Safety of Lamps and Lamp Systems”, (Published by the International Electrotechnical Commission in 2006). Photobiological risk can be divided into the following risk groups based on the degree of photobiological damage caused.

| Group (Safety Risk Category) |

Code | Description | Label |

|---|---|---|---|

| Exemption group | Exempt | Does not cause any form of photobiological damage. |  |

| Risk Group 1 (Low Risk) |

RG1 | Does not cause damage that would limit the victim’s normal functioning. |    |

| Risk Group 2 (Medium Risk) |

RG2 | Does not cause damage that would lead to the victim feeling nauseous or feeling any heat related discomfort. |      |

| Risk Group 3 (High Risk) |

RG3 | Damage is caused by temporary or short duration exposure to light. |

About UKCA Marking

The UKCA (UK Conformity Assessed) Mark is a certification mark of conformity with safety standards applicable to goods placed on the market in the island of Great Britain (England, Wales and Scotland).

Any product bearing the UKCA Mark conforms to the technical requirements that must be met (mandatory requirements) and the conformity assessment process and standards criteria that can be used to demonstrate conformity.

About UL

We have judged that our Lighting Equipment and extension cables are not covered by US safety standard, the Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use-UL61010-1, 6.3.1 a, due to their use of voltage under DC 48V.

Although we have Lighting Equipment controllers that meet the US safety standard, we do not plan on acquiring the certification as it is not mandatory.

About Electrical Appliance and Material Safety Law (PSE)

Products with the PSE mark conform to the technical standards specified by paragraph (1) of the Ministerial Ordinance of Specified Electrical Appliances (DC Controller Units)

About China Compulsory Certificate (CCC)

| Product | HS code | Description |

|---|---|---|

| Lighting | 9405.42 000 | We judged that the HS code of our product falls in the category of regulation subjects of the 2020 Certification and Accreditation Administration of the People’s Republic of China No. 21 but is non-applicable due to industrial use. |

| Controller(AC Input) | 8504.40 110 | We judged that the HS code of our product falls outside the category of regulation subjects and is not subject to regulation for the 2020 Certification and Accreditation Administration of the People’s Republic of China No. 21. |

| Controller (DC Input) | 8504.40 900 | The HS code of our product for the 2020 Certification and Accreditation Administration of the People’s Republic of China No. 21 is included in the classification of the regulation subject but we judged that it is not applicable due to the input/output voltage is less than AC/DC 36 V. |

| PoE Controller | 8504.40 900 | The HS code of our product for the 2020 Certification and Accreditation Administration of the People’s Republic of China No. 21 is included in the classification of the regulation subject but we judged to be out of consideration for items subject to certification. |

| Extension Cable | 8544.42.200 | We judged that the HS code of our product falls outside the category of regulation subjects and is not subject to regulation for the 2020 Certification and Accreditation Administration of the People’s Republic of China No. 21. |