Starter kit for high-speed lighting synchronous image acquisition

series

High-speed lighting synchronous image acquisition system

Optimal starter kit for high-speed lighting synchronous image acquisition system

It enables easy evaluation of the image composition algorithms represented by the illuminance difference stereo and multiple imaging synchronized with illumination direction switching.

It is effective for cases that are difficult using regular imaging, such as character inspection for shiny objects of metals and resins, marking and dents inspections of castings and patterned surfaces, and fine scratch detection. We offer an all-in-one solution of hardware, software, and algorithms including [split lighting], [controller], [I/O cable], [sample program], etc.

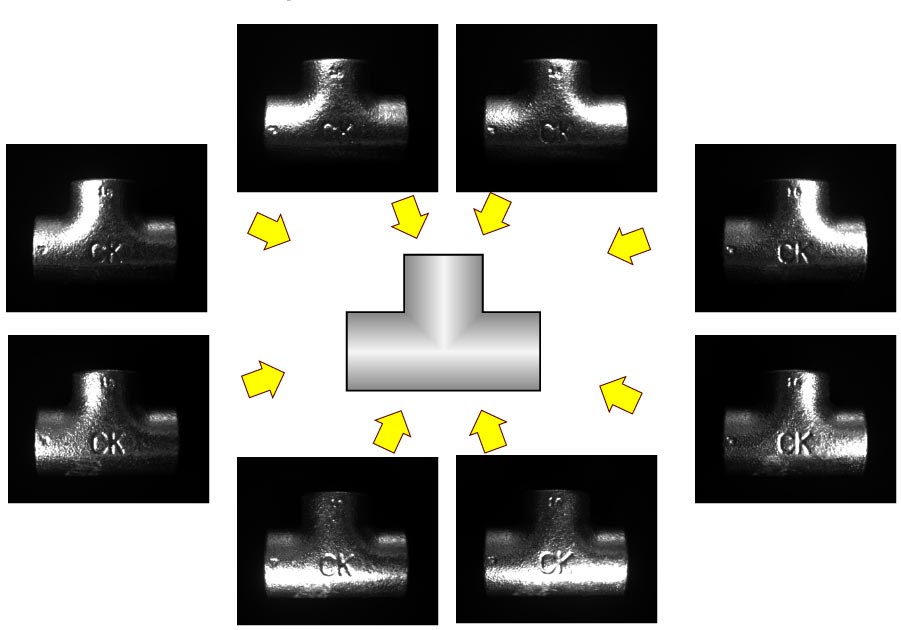

Imaging by multi-division illumination

|

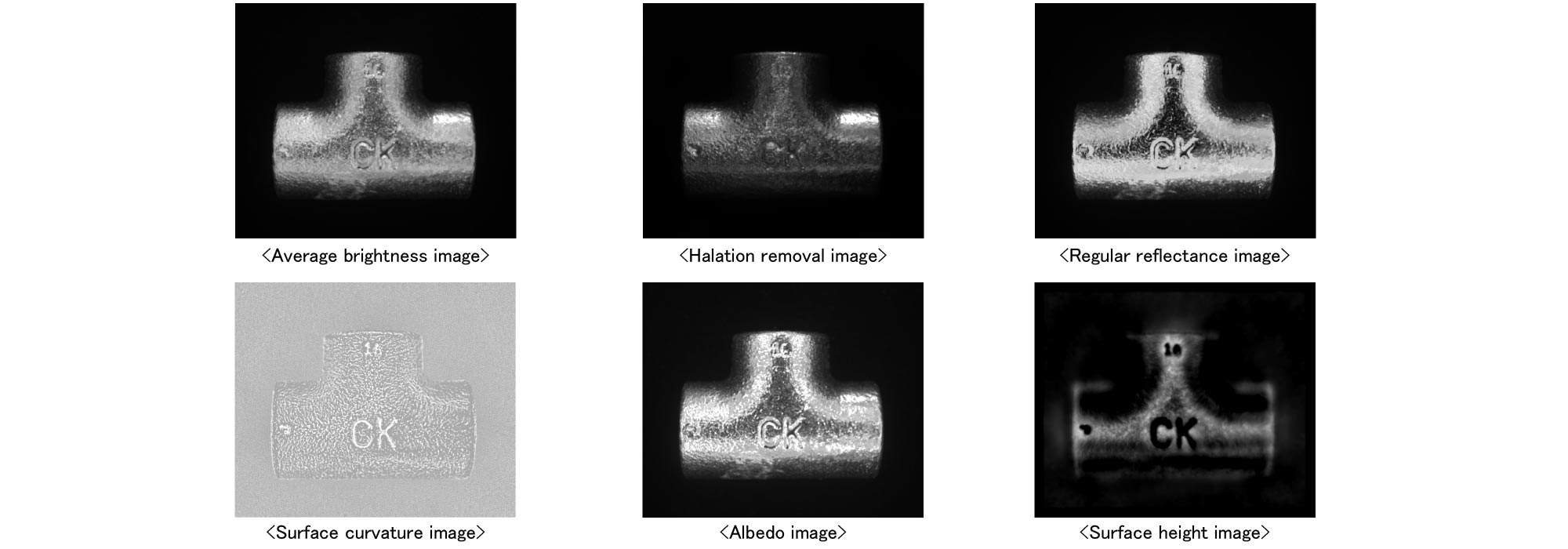

The following effects can be confirmed by illuminating light from different directions on the target object with the high-speed lighting synchronous image acquisition Starter kit. – Halation removal

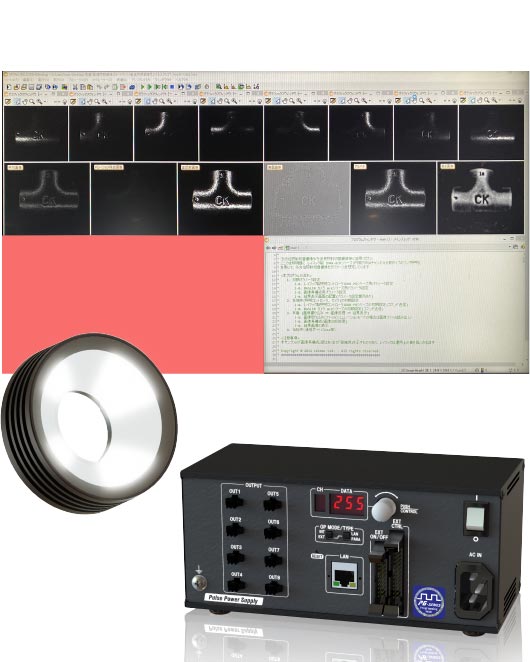

Imaging tests can be easily performed by combining our split lighting, high-performance controller, and control software. |

|---|

Easy configuration via sample application

Split lighting

| Lighting Type | Series | Channel Number | Light Color |

|---|---|---|---|

| Multi-position Ring Light | IMAR-D_-8ch series | 8CH |    |

| Low Angle Direct Ring Light | IDR-LA-8ch series | 8CH |    |

| Horizontal Opposed Ring Light | IDRA-T-8ch series | 8CH |    |

| Bar Light | IDBA-Q series | 4CH |     |

| Dome Light with 16ch-division | IDD-CB series | 16CH |  |

It is an example of the illumination that can be divided into 4ch, 8ch, and 16ch.

In addition, we have an abundance of multi-split lighting products, and customization is also possible.

Please contact our sales representative for details.

We will assist you in selecting the most suitable lighting.

Controller

| Output Control Method | Series | Maximum number of channels |

|---|---|---|

| PWM | IDGC-HS series | 8CH |

| PWM | IDMU series | 8CH |

| OverDrive | IJS series | 8CH |

It is a controller that supports high-speed lighting synchronous image acquisition.

Camera I/O Cable

| Series | Compatible Camera Series | Compatible Controller |

|---|---|---|

| IC-MIL-BA-26 | BASLER ace series | IDGC-HS series |

| IC-MIL-BA-20 | BASLER ace series | IJS series |

| IC-MIL-BA2-26 | BASLER ace2 series | IDGC-HS series |

| IC-MIL-BA2-20 | BASLER ace2 series | IJS series |

It is the I/O cable for the camera with the trigger output function used for high-speed lighting synchronous image acquisition.

Extension cables for split lighting

| Series | Connection number of channels | Remarks |

|---|---|---|

| I-CB-F | 4ch | Extension cables for 12V DC |

| I-CB-F_-24 | 4ch | Extension cables for 24V DC |

| I-CB-F_R-C02 | 4ch | Extension robot cable for 12V DC |

| I-CB-F_R-24-C02 | 4ch | Extension robot cable for 24V DC |

It is an extension cable for split lighting.

Robot cables have excellent flex resistance and torsion resistance, and are used for mechanical parts with moving parts.

Image Synthesis Sample Program

Please contact our sales representative regarding the provision of image synthesis sample programs used for high-speed lighting synchronous image acquisition.

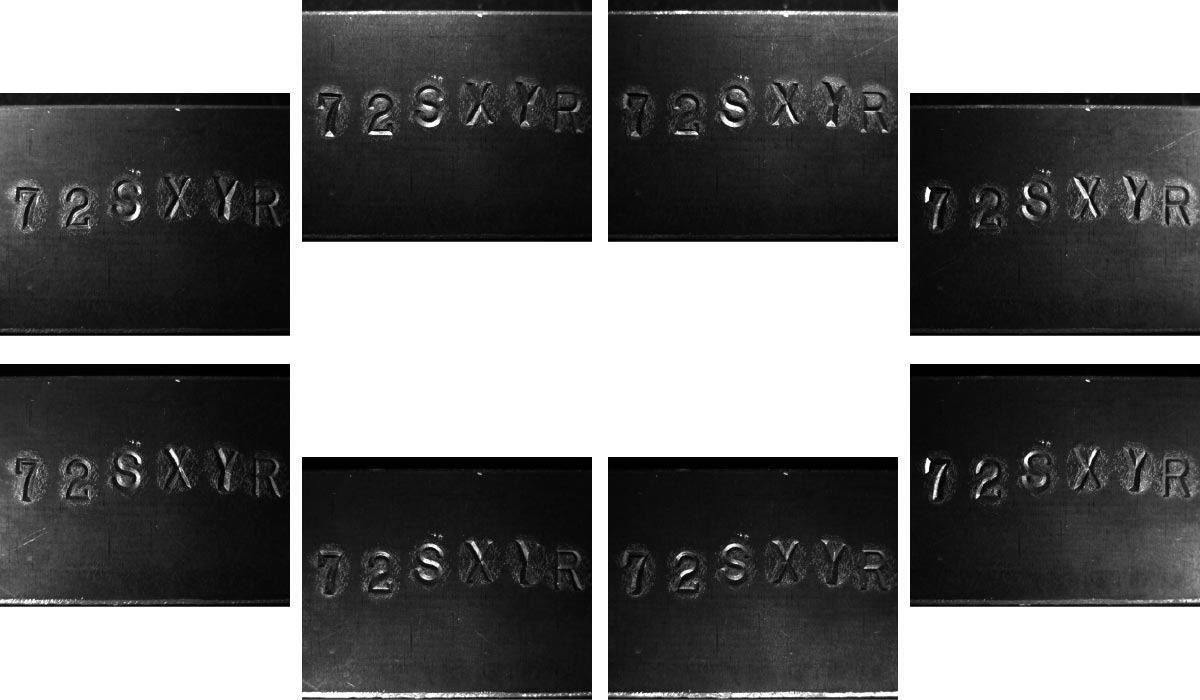

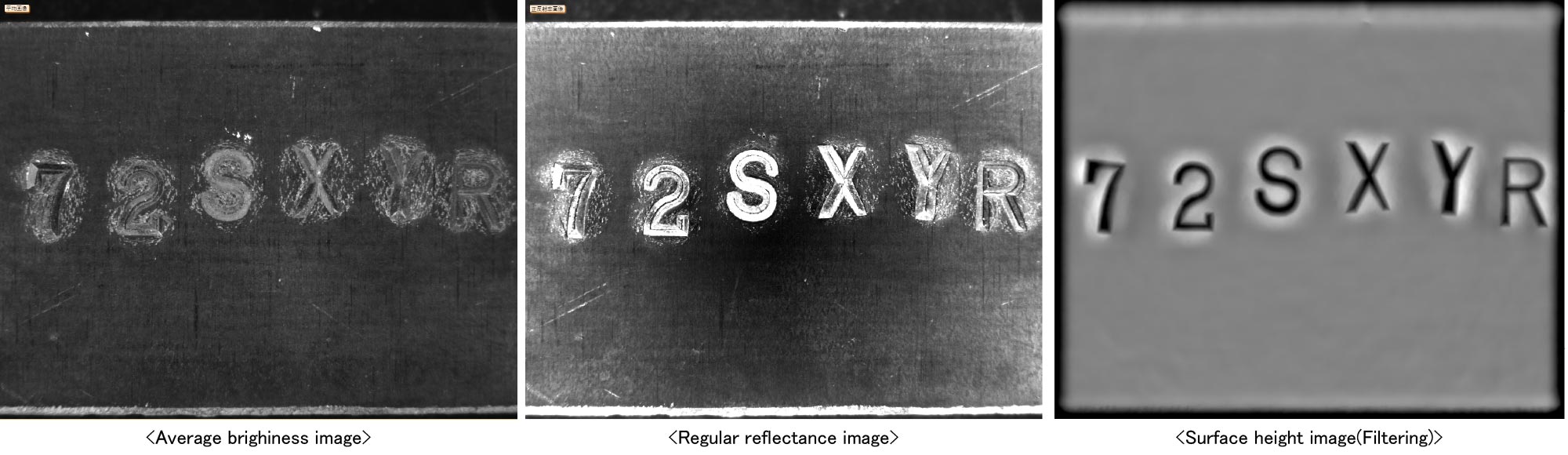

Imaging example: Marking inspection on metal objects

|

|

|

|---|---|---|

|

Object: Marking detection on metal plates |

||

|

||

|

– The reflection of the metal itself can be suppressed in the average image, whereas the roughness of the surface remains, and it becomes an image that is difficult to distinguish from the engraving. – Defects visible by light from a specific direction, such as scratches, are emphasized in canonical reflectance images, whereas the roughness of the surface is also emphasized, making it difficult to distinguish from the engraved mark. – The height image (filter processing) suppresses defects that were vaguely visible such as surface roughness, and images where the marking is clearly visible can be captured. |

||

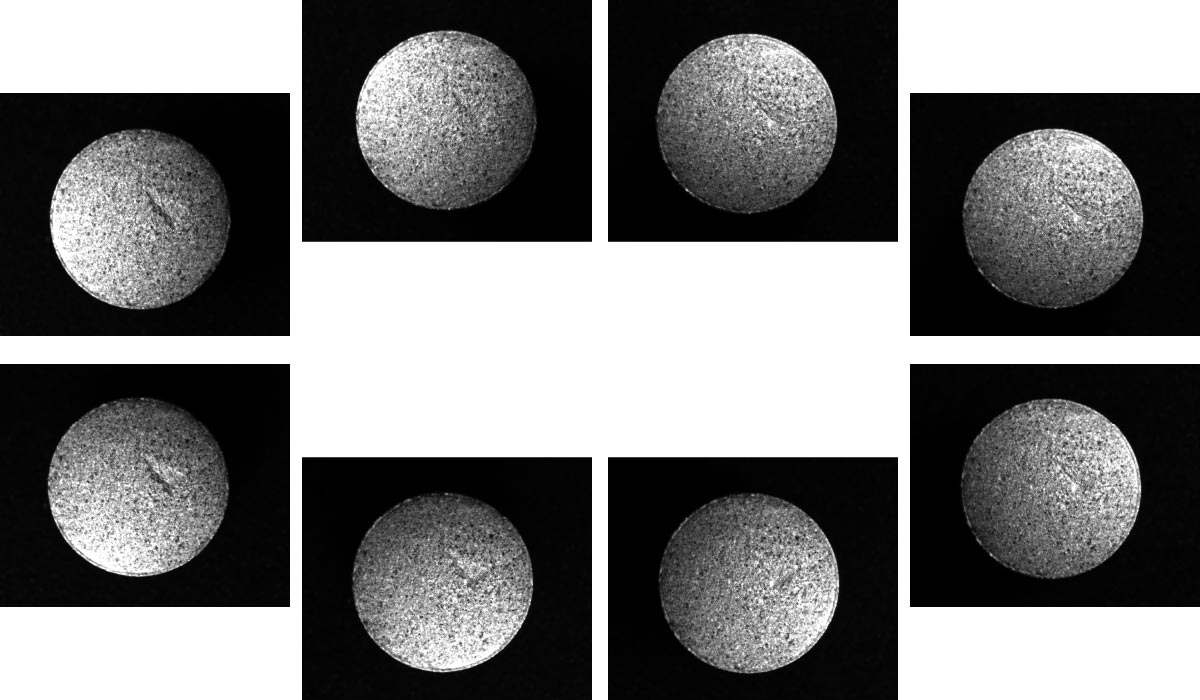

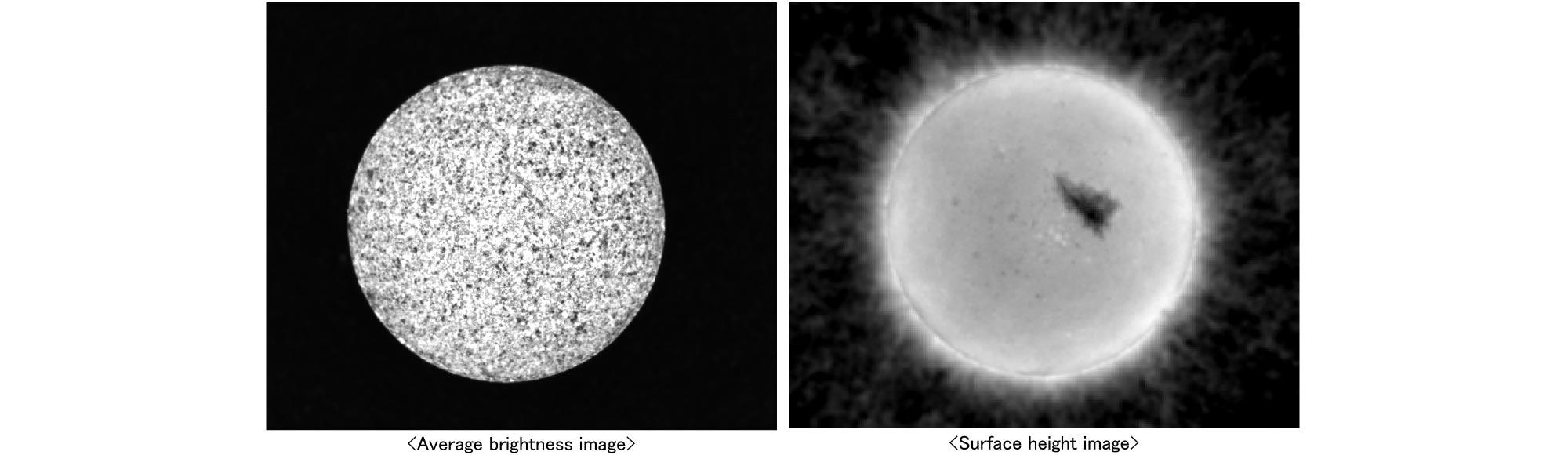

Imaging example: Detection of missing tablets

|

|

|

|---|---|---|

|

Object: Tablet with mottled surface |

||

|

||

|

– The mottled pattern is clearly visible in the average image, and it can be confirmed when there is a contamination on the material, whereas the defect state of the surface becomes an image that is difficult to judge. – With height image, the image better emphasizes more defects that are difficult to judge from individual images of split lighting, such as bruises on the tablet surface. |

||

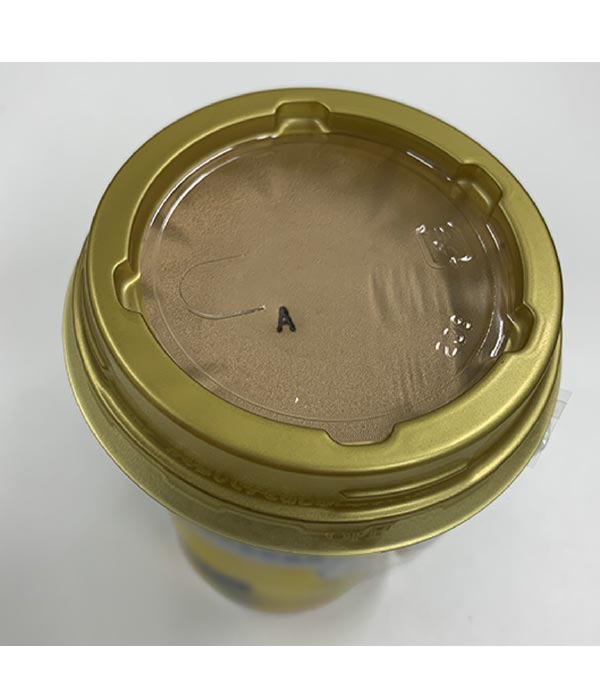

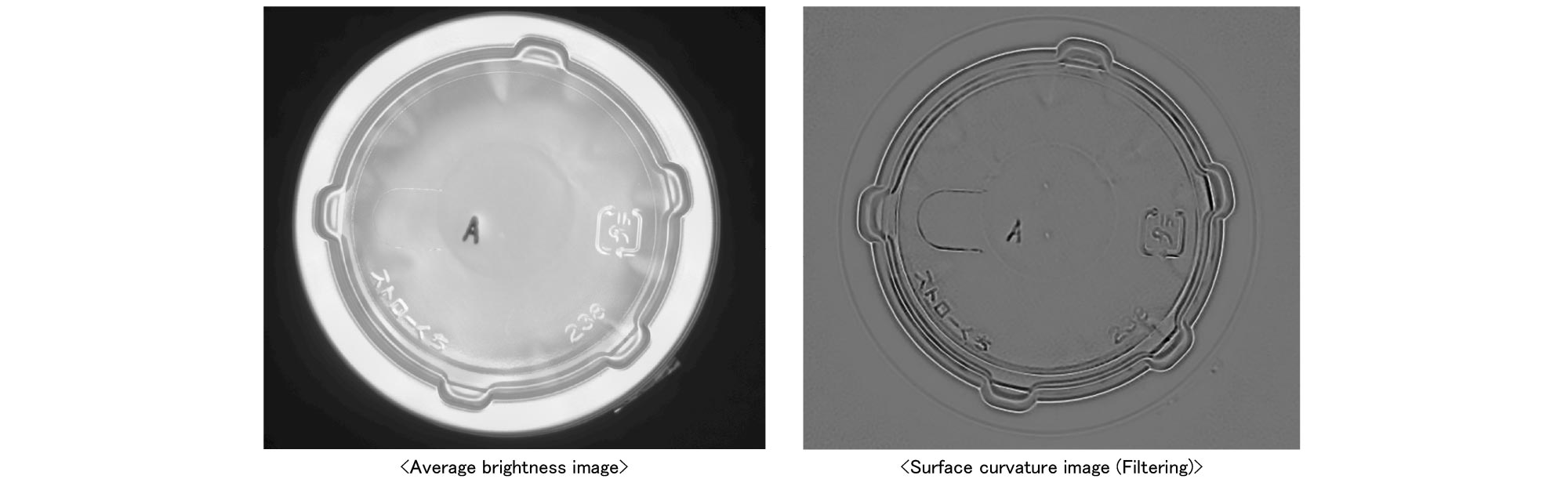

Imaging example: Cup container (Cutting line on transparent container, printing on the back side)

|

|

|

|---|---|---|

|

Cup container: Upper transparent cutting line over the container, Printing over the back side film |

||

|

||

|

– It is easy to recognize uneven processing such as plastic and straw beak on the transparent container on the top, engravings such as 238, printing on the film on the back side, etc., in the average image. – It is easy to recognize the cutting process applied to the transparent container at the top in the surface curvature image (filter processing). |

||