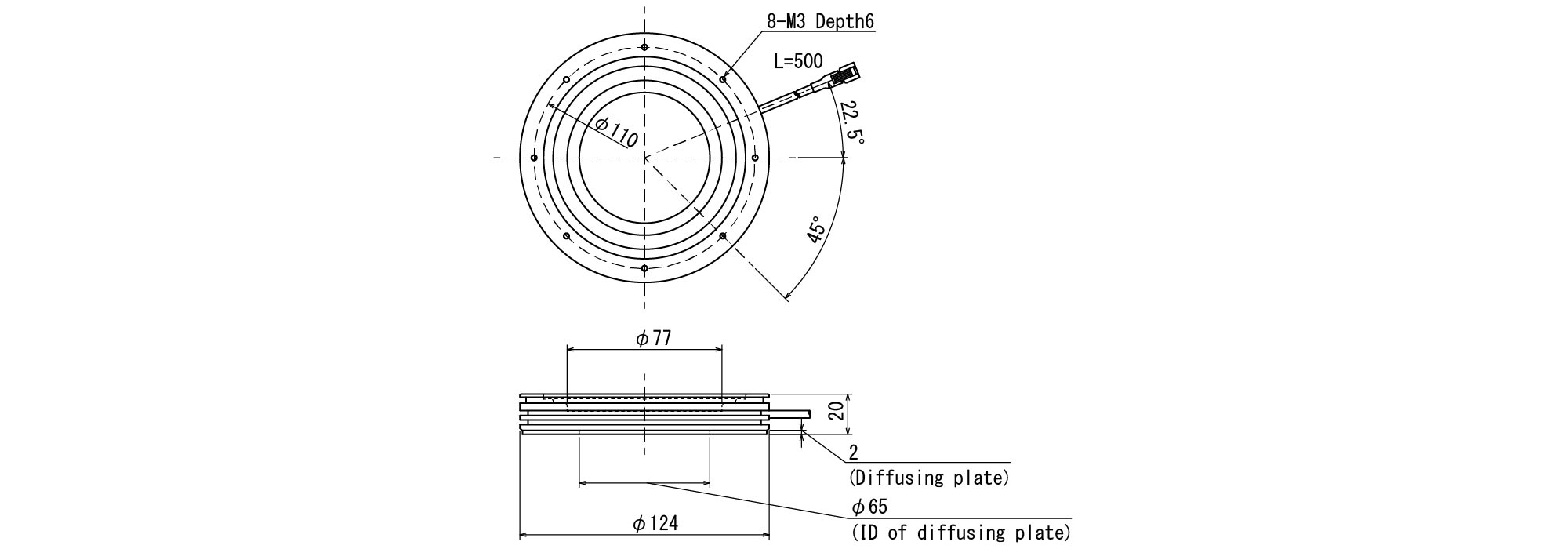

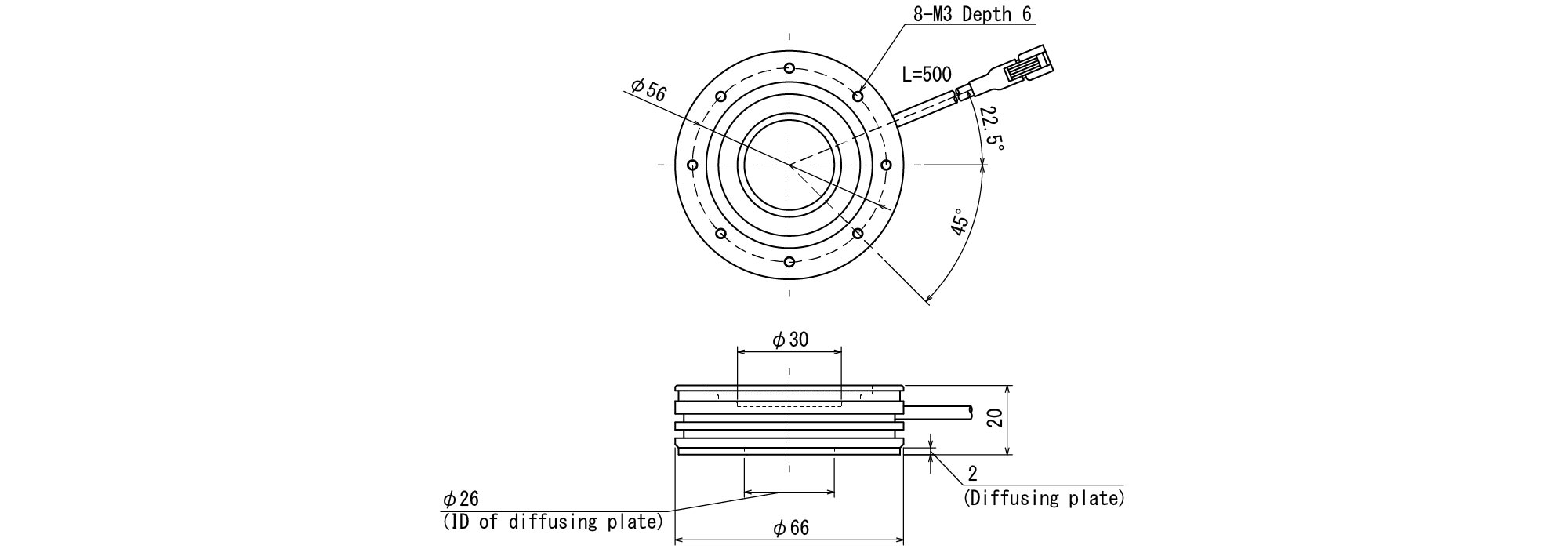

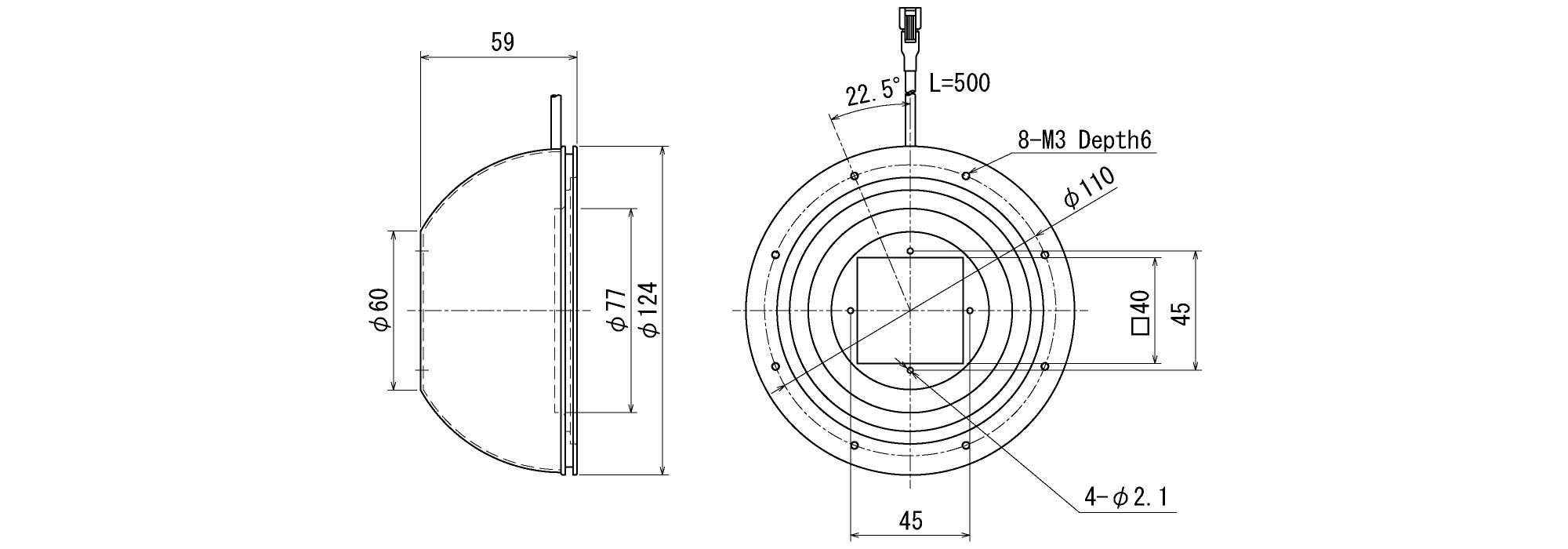

IHRB-120_SLightweight NEO Ring illumination – IHRB series

| Model | IHRB-120DWS | IHRB-120AWS | IHRB-120RS | IHRB-120BS | IHRB-120 IR-850S |

|---|---|---|---|---|---|

| Product Number | 340-740 | 340-743 | 340-742 | 340-741 | 340-744 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 13.5W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector(SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 265g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

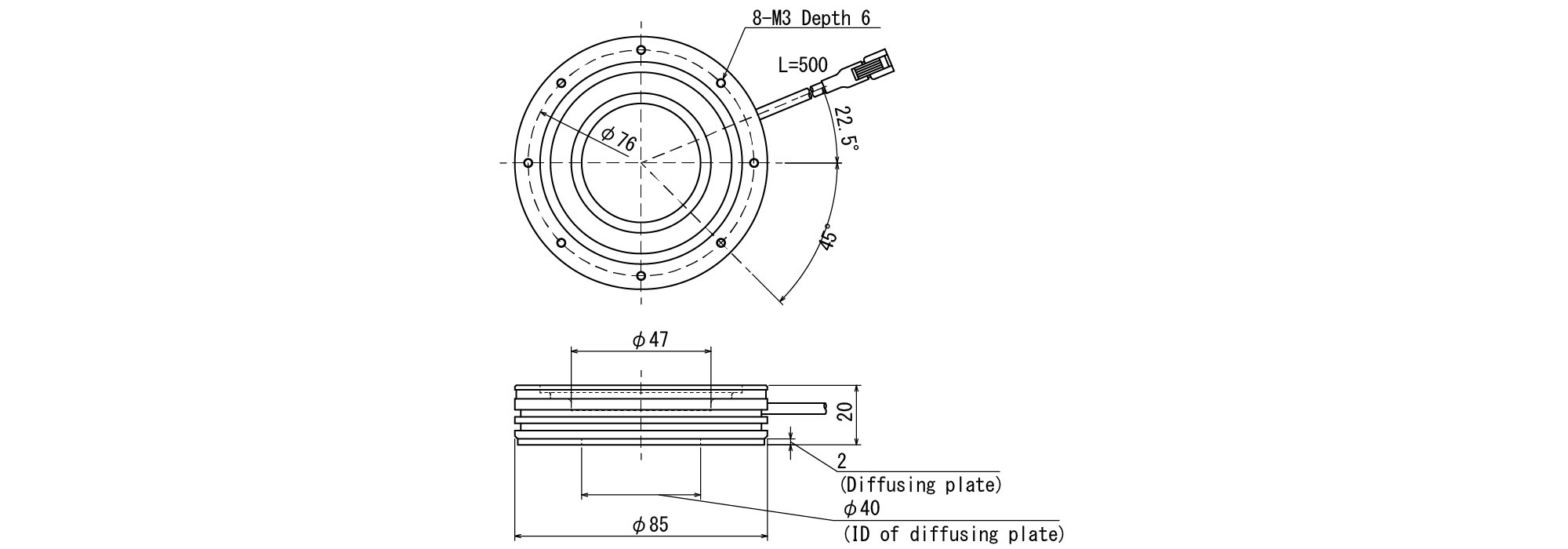

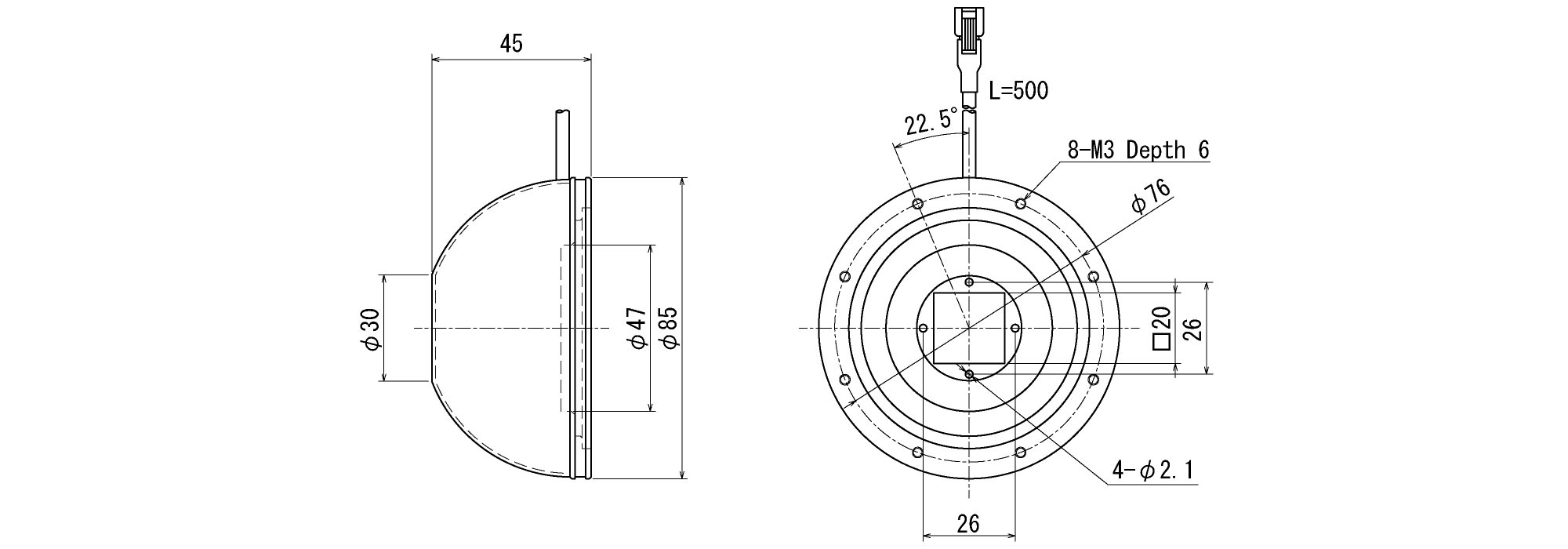

IHRB-80_S

IHRB-80_SLightweight NEO Ring illumination – IHRB series

| Model | IHRB-80DWS | IHRB-80AWS | IHRB-80RS | IHRB-80BS | IHRB-80 IR-850S |

|---|---|---|---|---|---|

| Product Number | 340-730 | 340-733 | 340-732 | 340-731 | 340-734 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 9W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector(SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 135g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

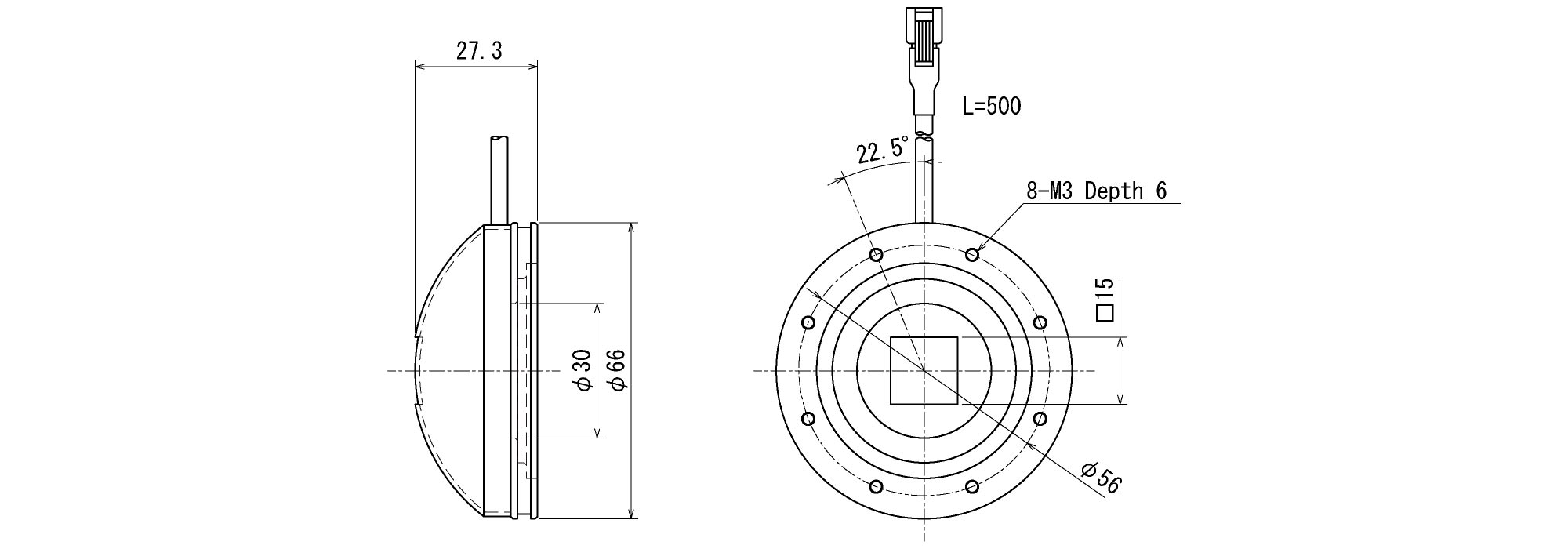

IHRB-60_S

IHRB-60_SLightweight NEO Ring illumination – IHRB series

| Model | IHRB-60 DWS |

IHRB-60 AWS |

IHRB-60 RS |

IHRB-60 BS |

IHRB-60 IR-850S |

|---|---|---|---|---|---|

| Product Number | 340-780 | 340-783 | 340-782 | 340-781 | 340-784 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 6.5W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector(SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 105g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH220_HV

IDDB-KH220_HVLightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH220 DWHV |

IDDB-KH220 AWHV |

IDDB-KH220 RHV |

IDDB-KH220 BHV |

IDDB-KH220 IR-850HV |

|---|---|---|---|---|---|

| Product Number | 350-769 | 350-767 | 350-766 | 350-765 | 350-768 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC24V | ||||

| Power Consumption | 28.5W | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-03V-B) | ||||

| Polarity | 1:+ 2:NC 3:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 455g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH150_HV

IDDB-KH150_HVLightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH150 DWHV |

IDDB-KH150 AWHV |

IDDB-KH150 RHV |

IDDB-KH150 BHV |

IDDB-KH150 IR-850HV |

|---|---|---|---|---|---|

| Product Number | 350-759 | 350-757 | 350-756 | 350-755 | 350-758 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC24V | ||||

| Power Consumption | 18W | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-03V-B) | ||||

| Polarity | 1:+ 2:NC 3:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 260g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH120_HV

IDDB-KH120_HVLightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH120 DWHV |

IDDB-KH120 AWHV |

IDDB-KH120 RHV |

IDDB-KH120 BHV |

IDDB-KH120 IR-850HV |

|---|---|---|---|---|---|

| Product Number | 350-749 | 350-747 | 350-746 | 350-745 | 350-748 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC24V | ||||

| Power Consumption | 13.5W | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-03V-B) | ||||

| Polarity | 1:+ 2:NC 3:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 195g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH80_HV

IDDB-KH80_HVLightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH80 DWHV |

IDDB-KH80 AWHV |

IDDB-KH80 RHV |

IDDB-KH80 BHV |

IDDB-KH80 IR-850HV |

|---|---|---|---|---|---|

| Product Number | 350-739 | 350-737 | 350-736 | 350-735 | 350-738 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC24V | ||||

| Power Consumption | 9W | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-03V-B) | ||||

| Polarity | 1:+ 2:NC 3:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 105g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH60_HV

IDDB-KH60_HVLightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH60 DWHV |

IDDB-KH60 AWHV |

IDDB-KH60 RHV |

IDDB-KH60 BHV |

IDDB-KH60 IR-850HV |

|---|---|---|---|---|---|

| Product Number | 350-789 | 350-787 | 350-786 | 350-785 | 350-788 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC24V | ||||

| Power Consumption | 6.5W | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-03V-B) | ||||

| Polarity | 1:+ 2:NC 3:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 90g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

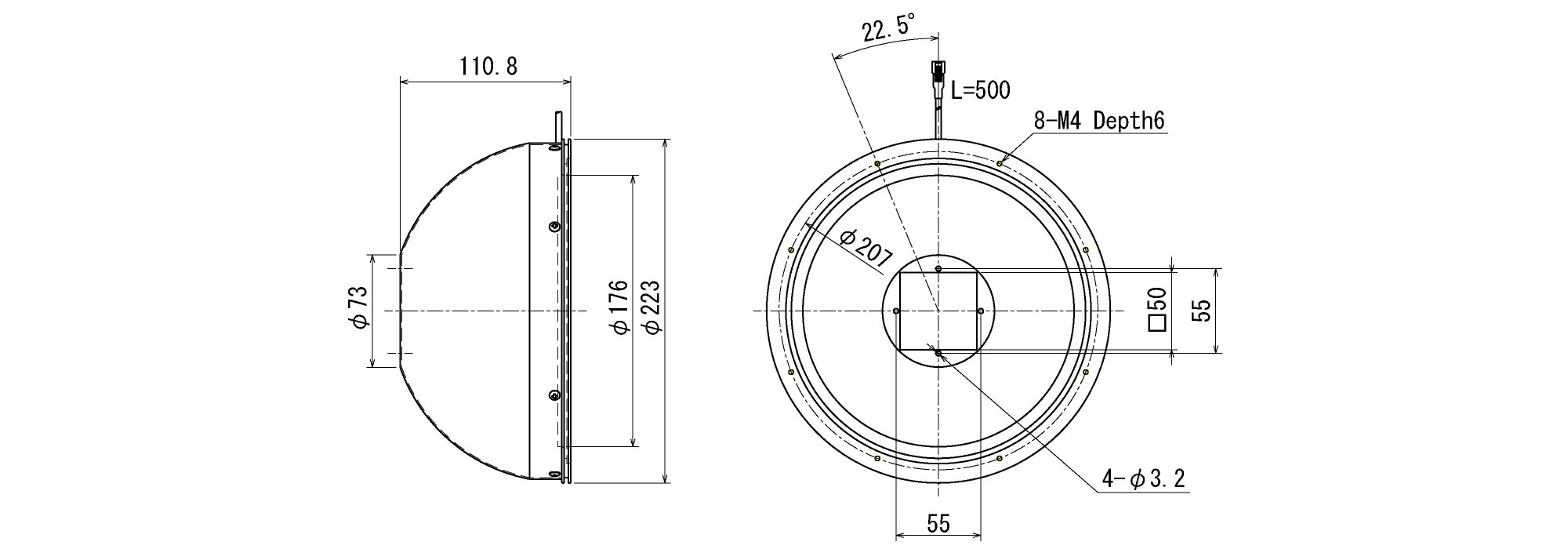

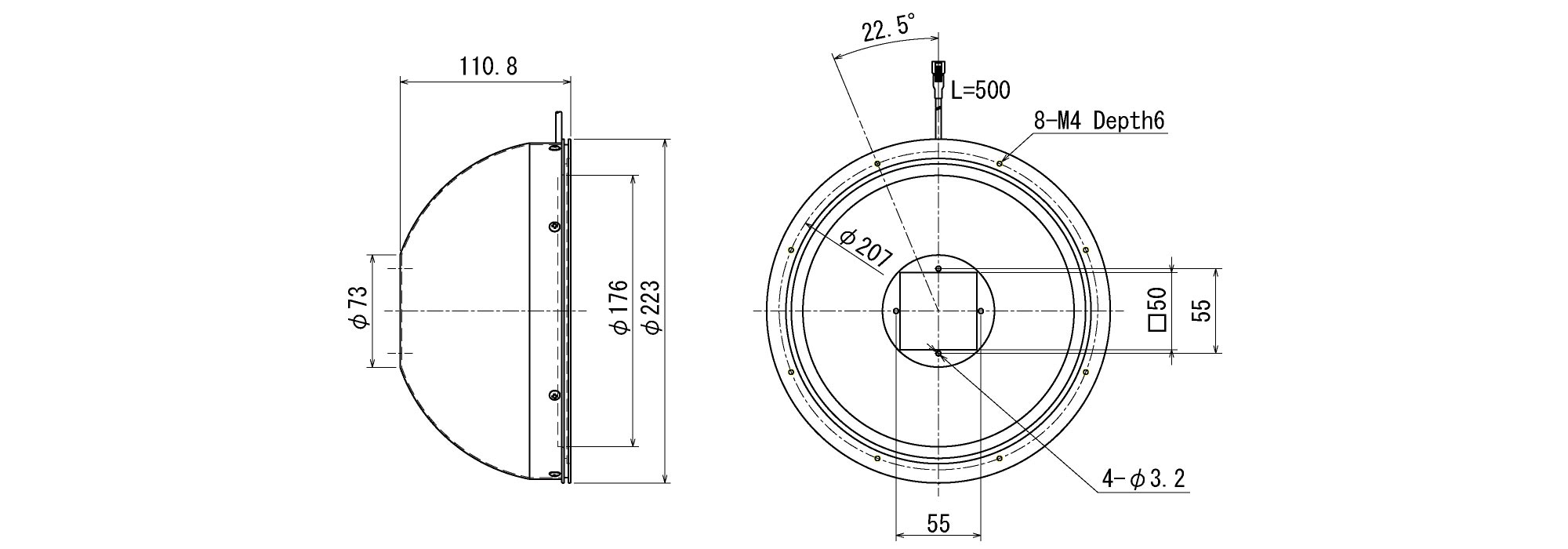

IDDB-KH220

IDDB-KH220Lightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH220 DW |

IDDB-KH220 AW |

IDDB-KH220 R |

IDDB-KH220 B |

IDDB-KH220 IR-850 |

|---|---|---|---|---|---|

| Product Number | 350-760 | 350-763 | 350-762 | 350-761 | 350-764 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 28.5W | ||||

| SAG Setting Value | C3 | FF | BC | FF | |

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 465g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

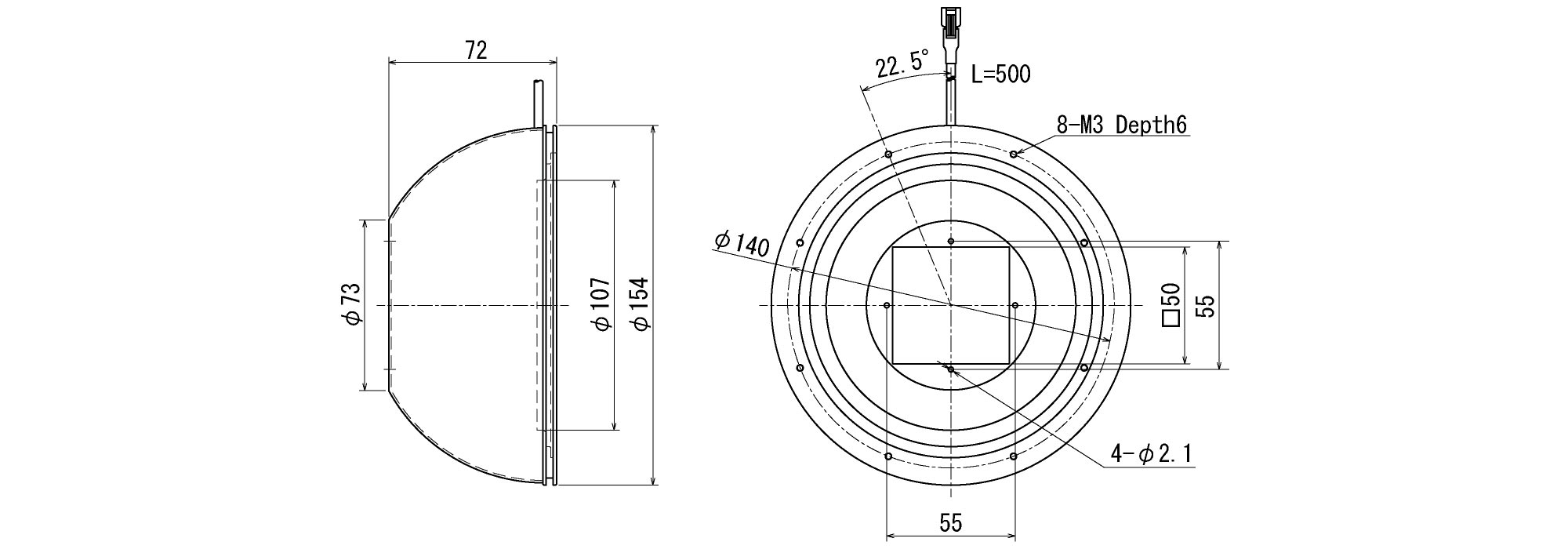

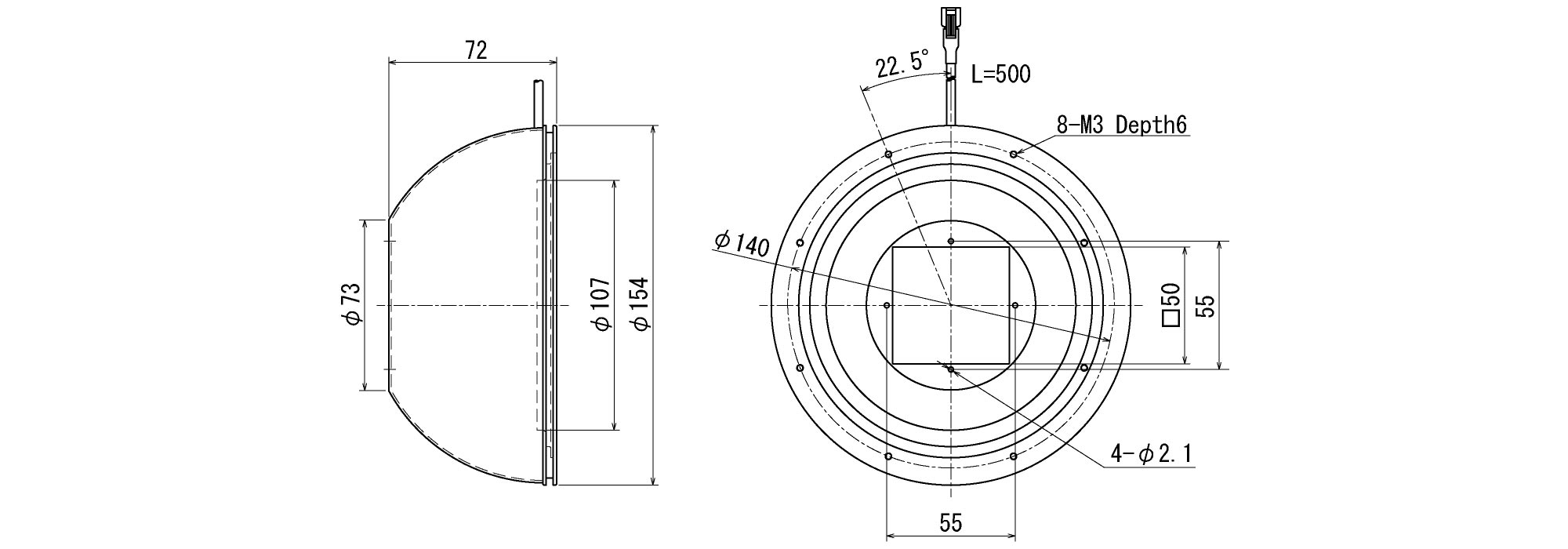

IDDB-KH150

IDDB-KH150Lightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH150 DW |

IDDB-KH150 AW |

IDDB-KH150 R |

IDDB-KH150 B |

IDDB-KH150 IR-850 |

|---|---|---|---|---|---|

| Product Number | 350-750 | 350-753 | 350-752 | 350-751 | 350-754 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 18W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 260g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

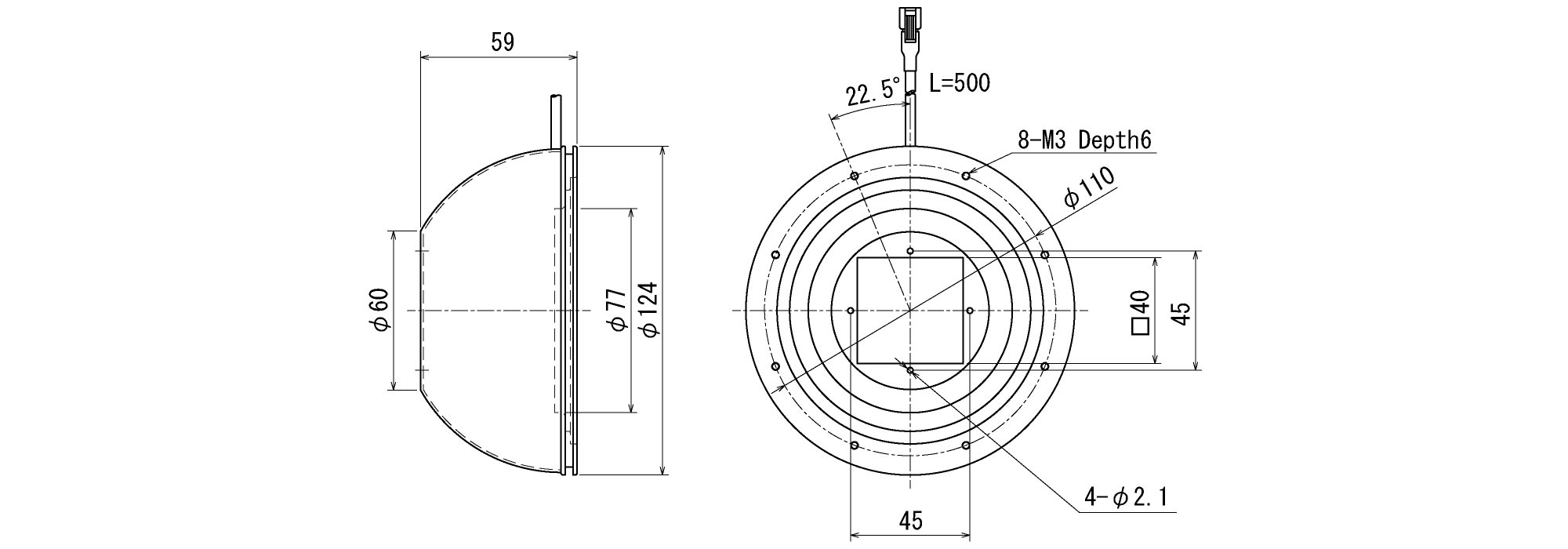

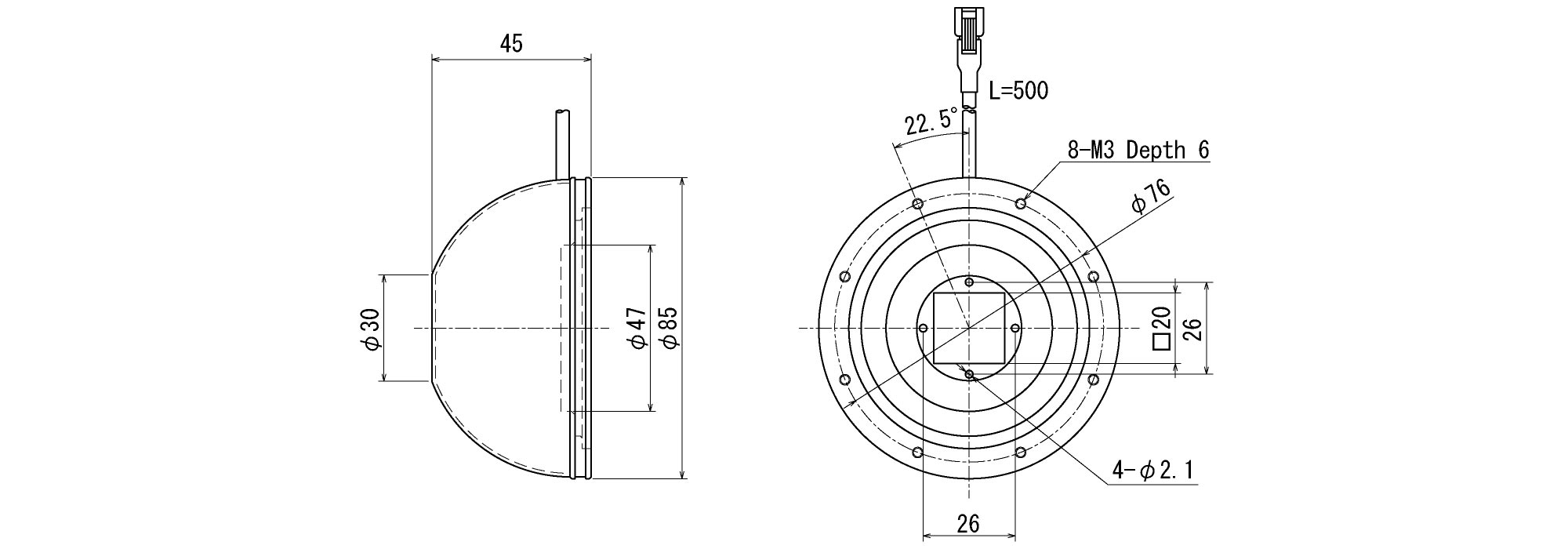

IDDB-KH120

IDDB-KH120Lightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH120 DW |

IDDB-KH120 AW |

IDDB-KH120 R |

IDDB-KH120 B |

IDDB-KH120 IR-850 |

|---|---|---|---|---|---|

| Product Number | 350-740 | 350-743 | 350-742 | 350-741 | 350-744 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 13.5W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 195g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

IDDB-KH80

IDDB-KH80Lightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH80 DW |

IDDB-KH80 AW |

IDDB-KH80 R |

IDDB-KH80 B |

IDDB-KH80 IR-850 |

|---|---|---|---|---|---|

| Product Number | 350-730 | 350-733 | 350-732 | 350-731 | 350-734 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 9W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 105g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

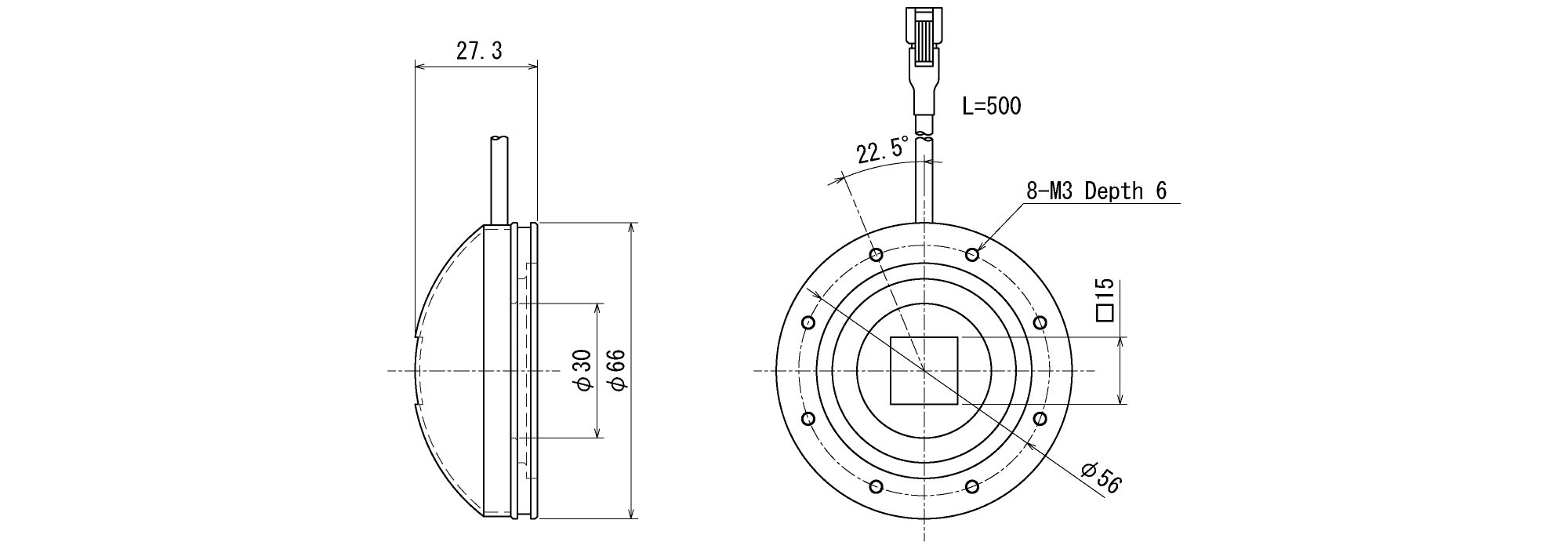

IDDB-KH60

IDDB-KH60Lightweight NEO Dome Illumination – IDDB-KH series

| Model | IDDB-KH60 DW |

IDDB-KH60 AW |

IDDB-KH60 R |

IDDB-KH60 B |

IDDB-KH60 IR-850 |

|---|---|---|---|---|---|

| Product Number | 350-780 | 350-783 | 350-782 | 350-781 | 350-784 |

| Color |  |

|

|

|

|

| Color temperature/Peak Wavelength | 5700K typ. | 4900K typ. | 635nm typ. | 465nm typ. | 850nm typ. |

| Input Voltage | DC12V | ||||

| Power Consumption | 6.5W | ||||

| SAG Setting Value | FF | ||||

| Cable Length | 500mm | ||||

| Input Connector | SM connector (SMR-02V-B) | ||||

| Polarity | 1:+ 2:- | ||||

| Operating Temperature | 0~+40℃ | ||||

| Operating Humidity | 35~85% (non condensing) | ||||

| Weight | 90g | ||||

| Conformity Standard |  IEC62471 |

||||

| RoHS Directive |  |

||||

| China RoHS |  |

||||

| Cables | |||||

| Controllers |

Check the output voltage of the compatible Controller. |

||||

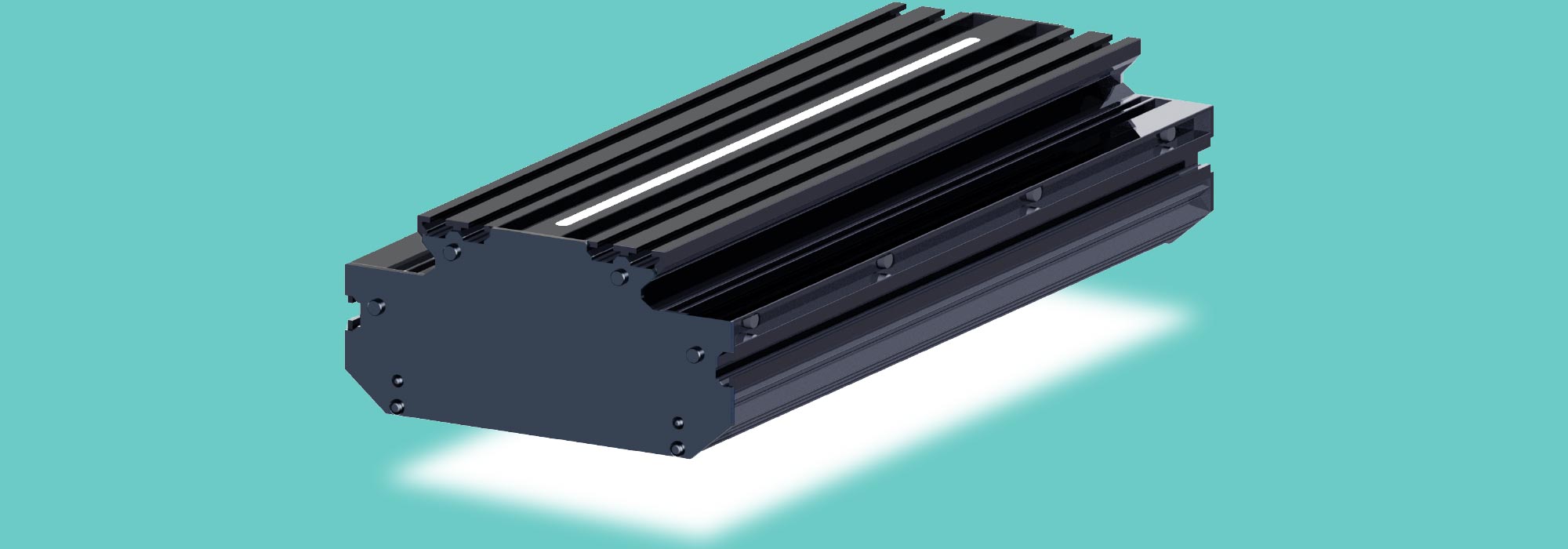

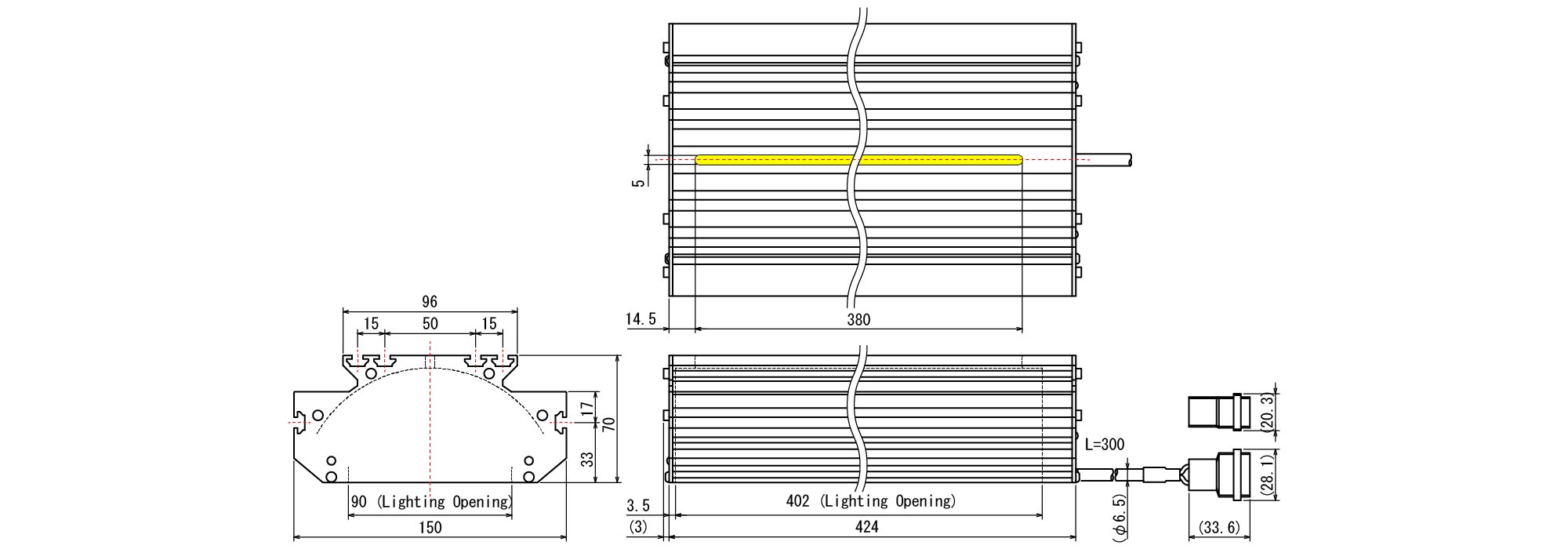

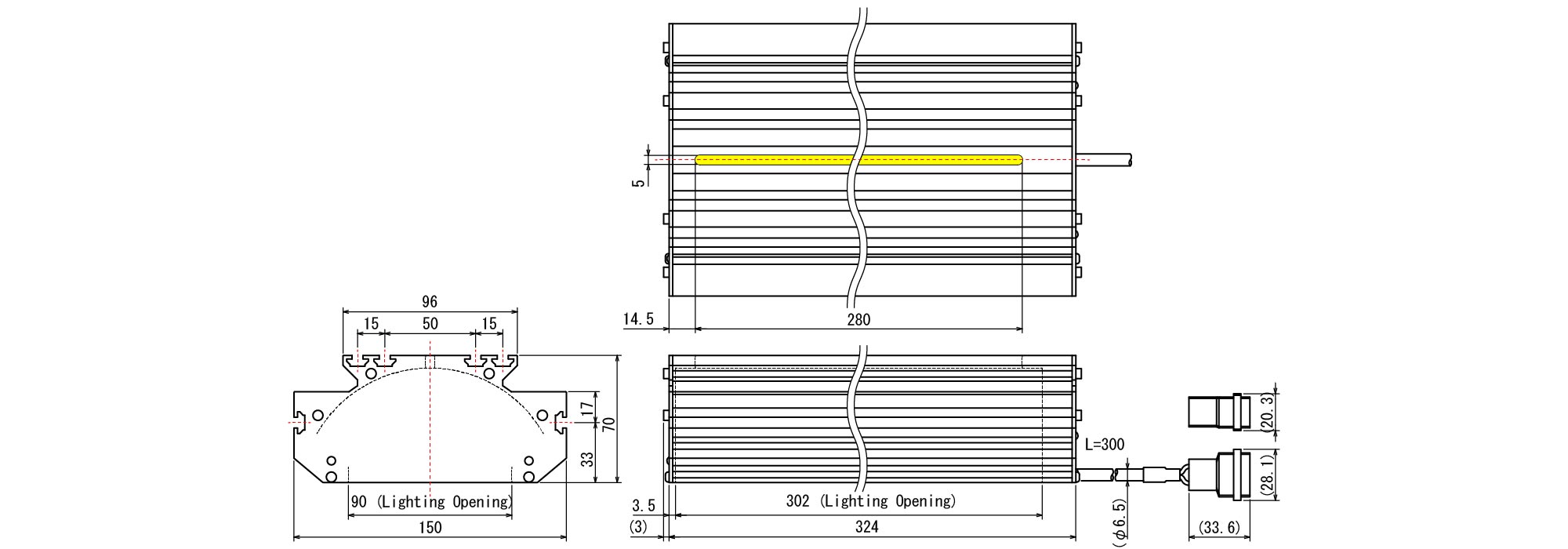

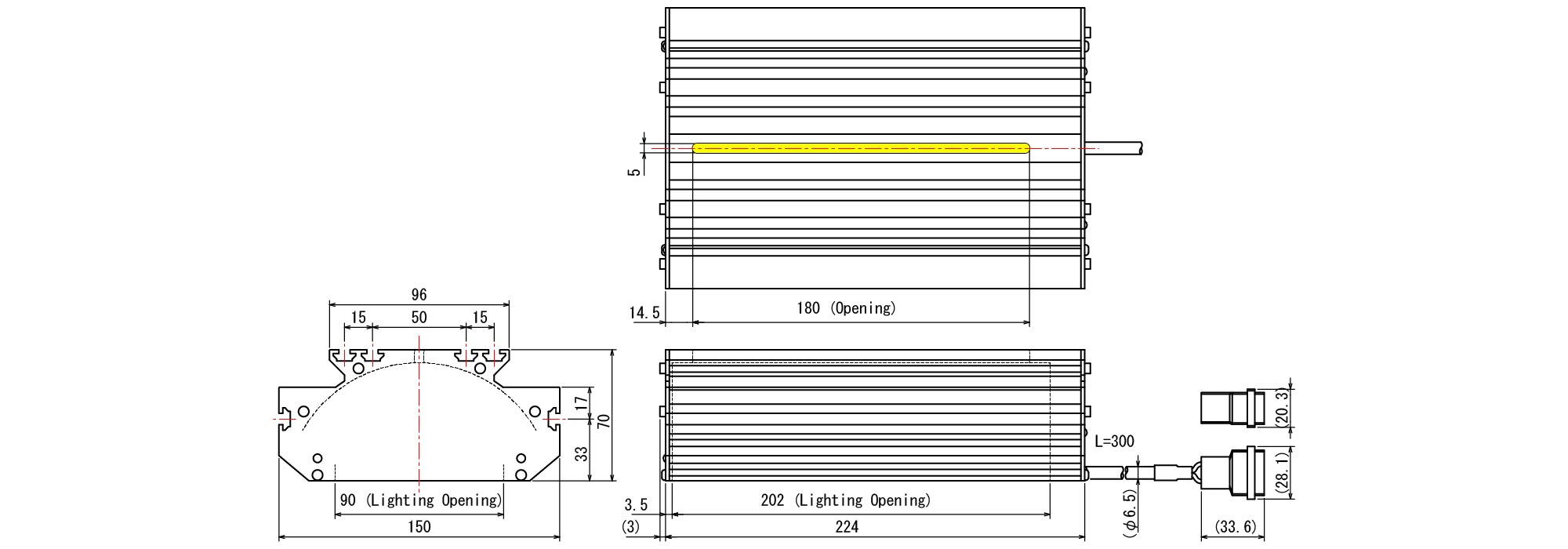

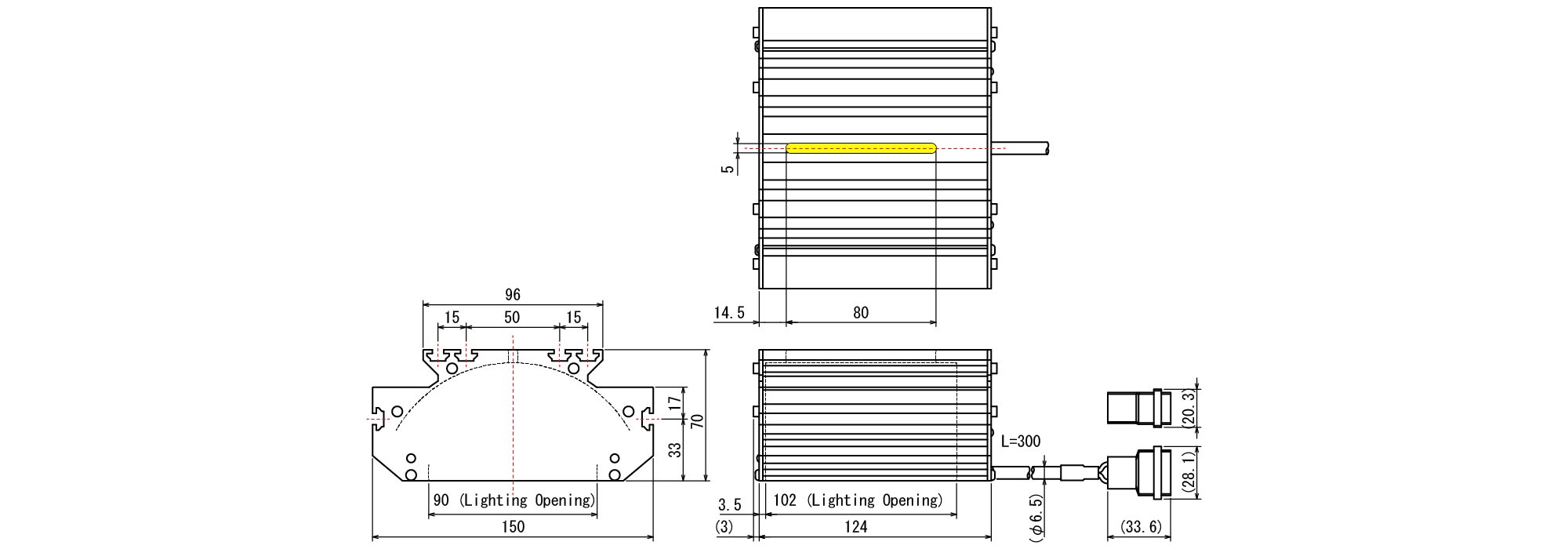

IQDH-RE series

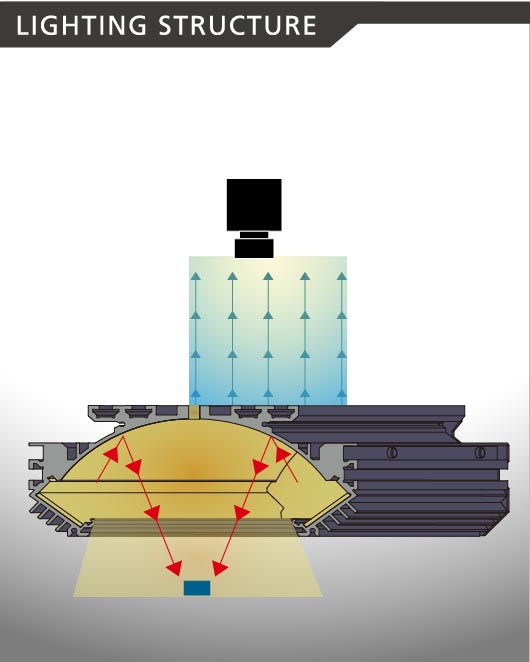

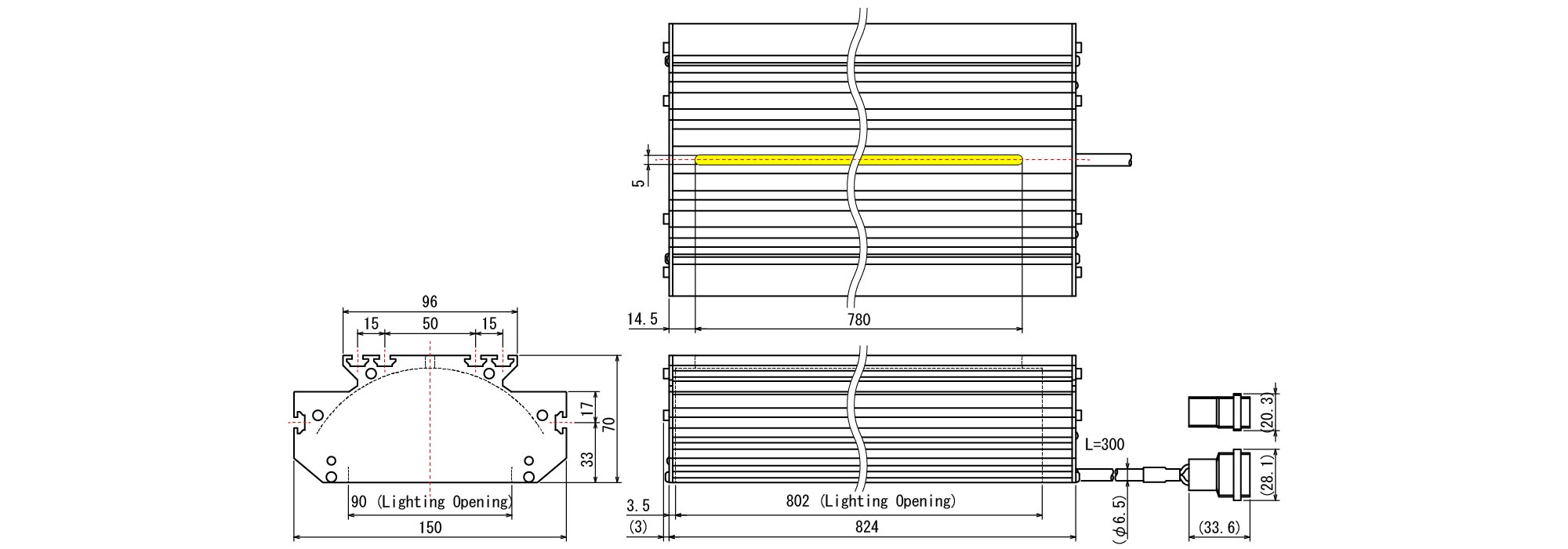

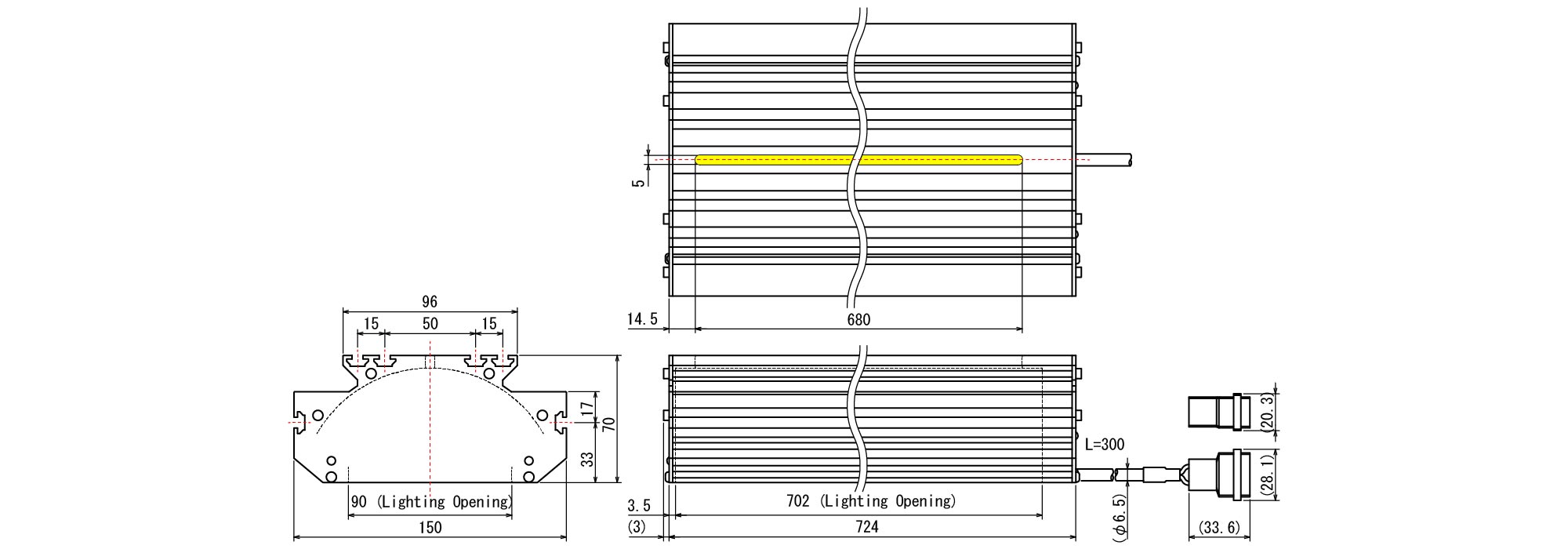

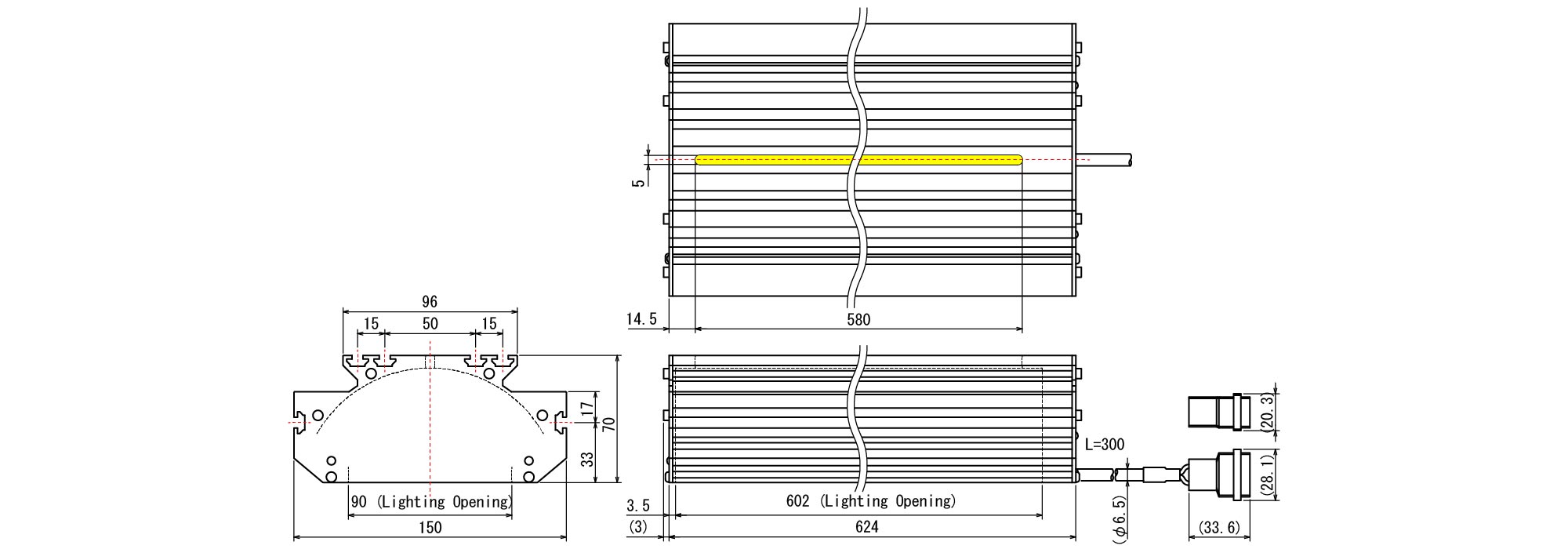

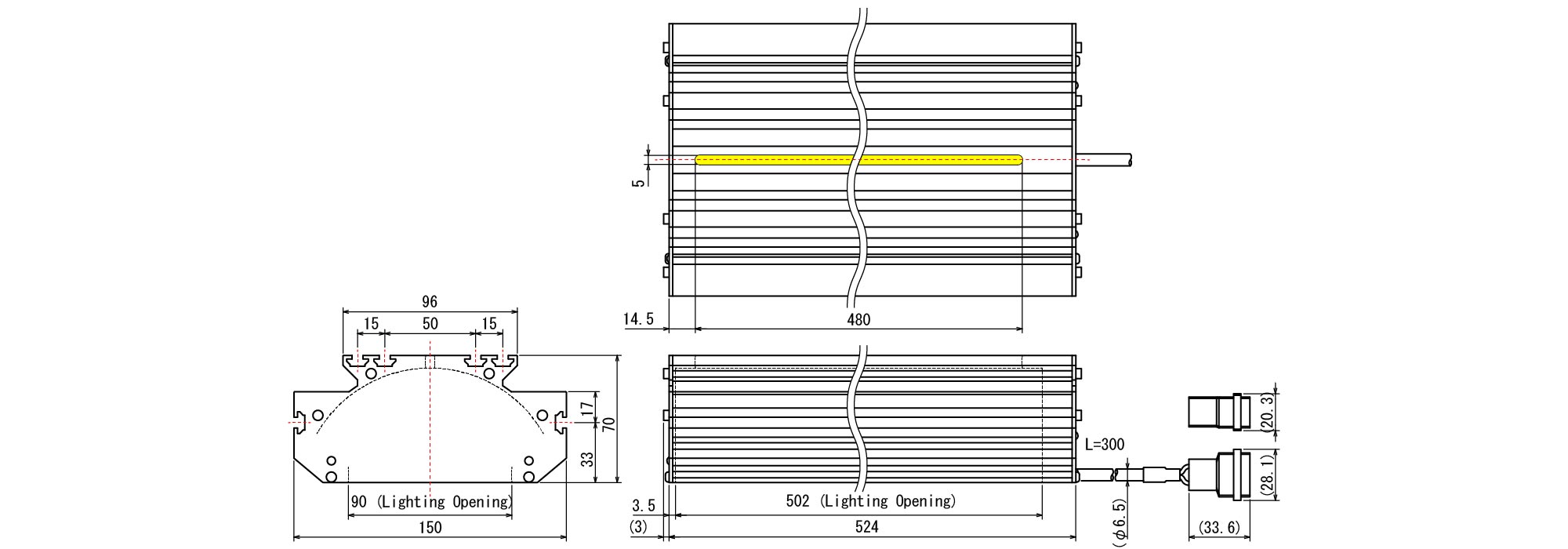

Half-pipe Light for Line-scan camerasIQDH-RE series

High-intensity half pipe lighting suitable for long objects.

Max 1000mm size is available as the standard.

High illuminance of 150,000 lx or more (LWD=10mm)

Available in 10 sizes with Lighting opening lengths from 124 mm to 1024 mm

| Model | Input Voltage | Color | Dimensions (W/D/H) |

|---|---|---|---|

| IQDH-RE100 | DC48V |  |

130mm/150mm/70mm |

| IQDH-RE200 | DC48V |  |

230mm/150mm/70mm |

| IQDH-RE300 | DC48V |  |

330mm/150mm/70mm |

| IQDH-RE400 | DC48V |  |

430mm/150mm/70mm |

| IQDH-RE500 | DC48V |  |

530mm/150mm/70mm |

| IQDH-RE600 | DC48V |  |

630mm/150mm/70mm |

| IQDH-RE700 | DC48V |  |

730mm/150mm/70mm |

| IQDH-RE800 | DC48V |  |

830mm/150mm/70mm |

| IQDH-RE900 | DC48V |  |

930mm/150mm/70mm |

| IQDH-RE1000 | DC48V |  |

1030mm/150mm/70mm |

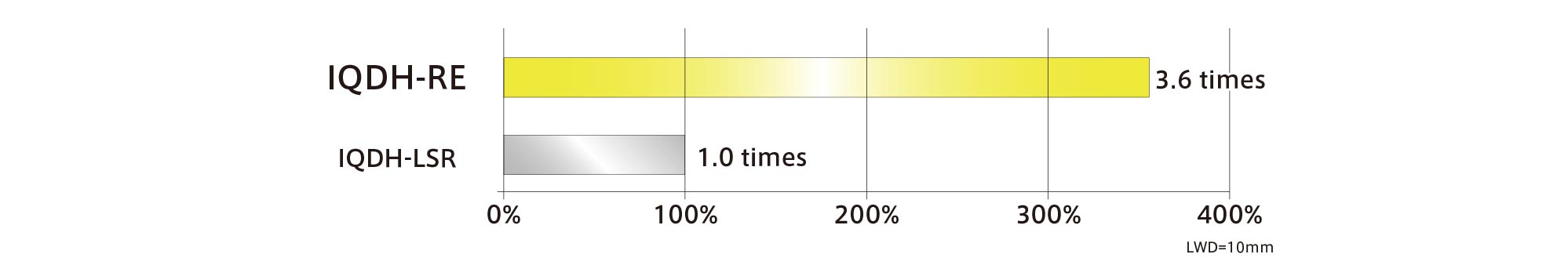

Approx. 3.6x brighter than conventional products

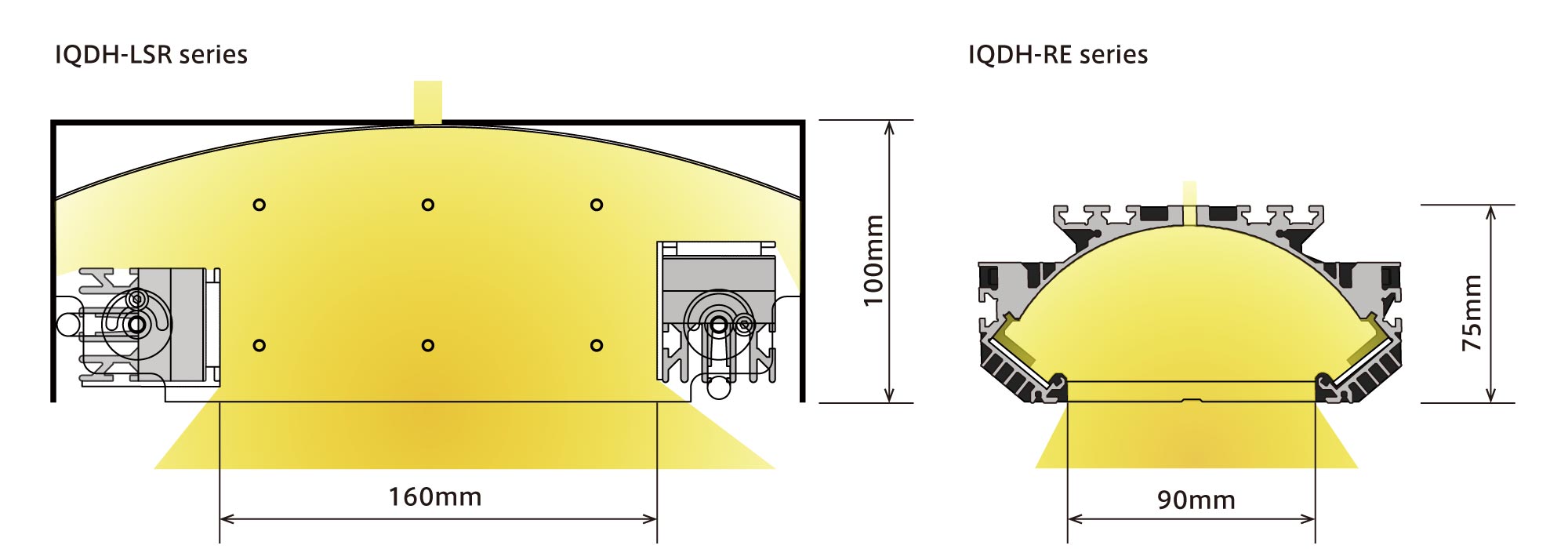

Shape comparison with IQDH-LSR

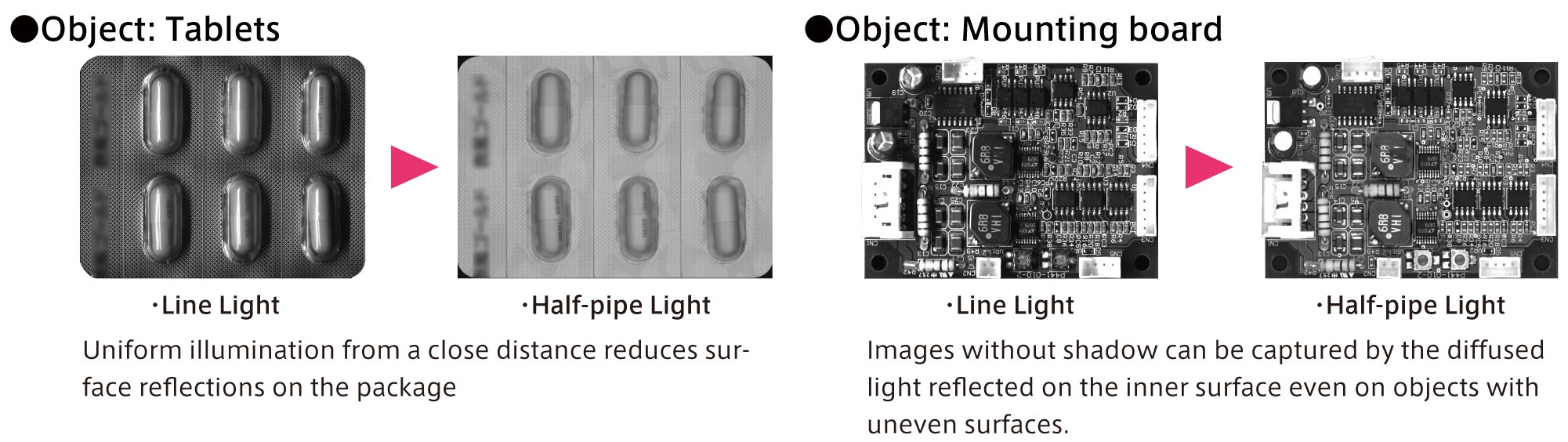

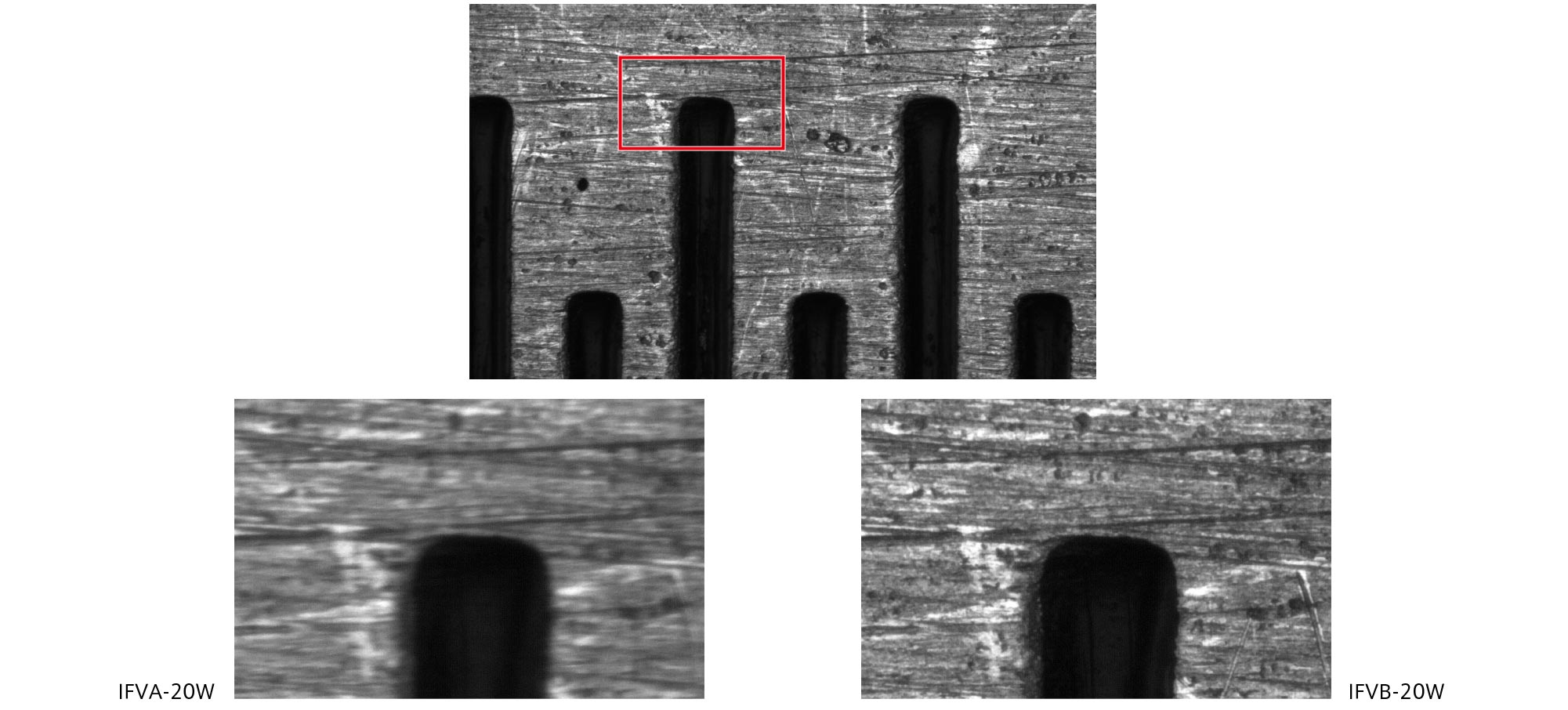

Imaging Example

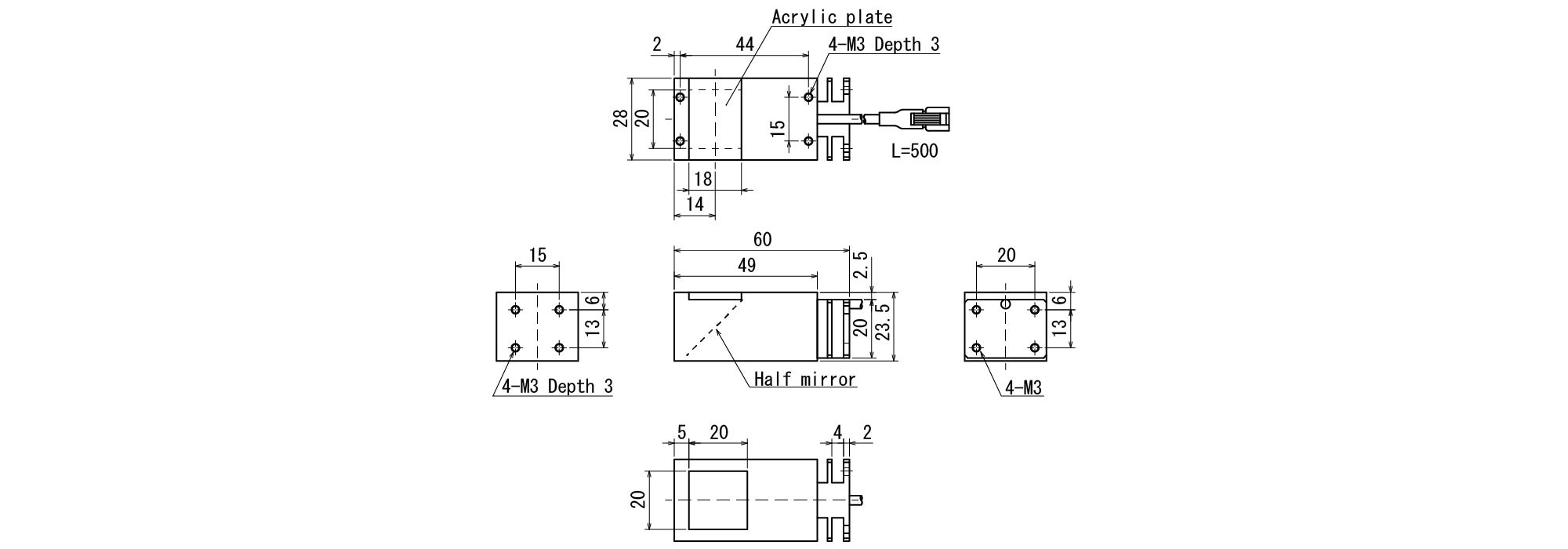

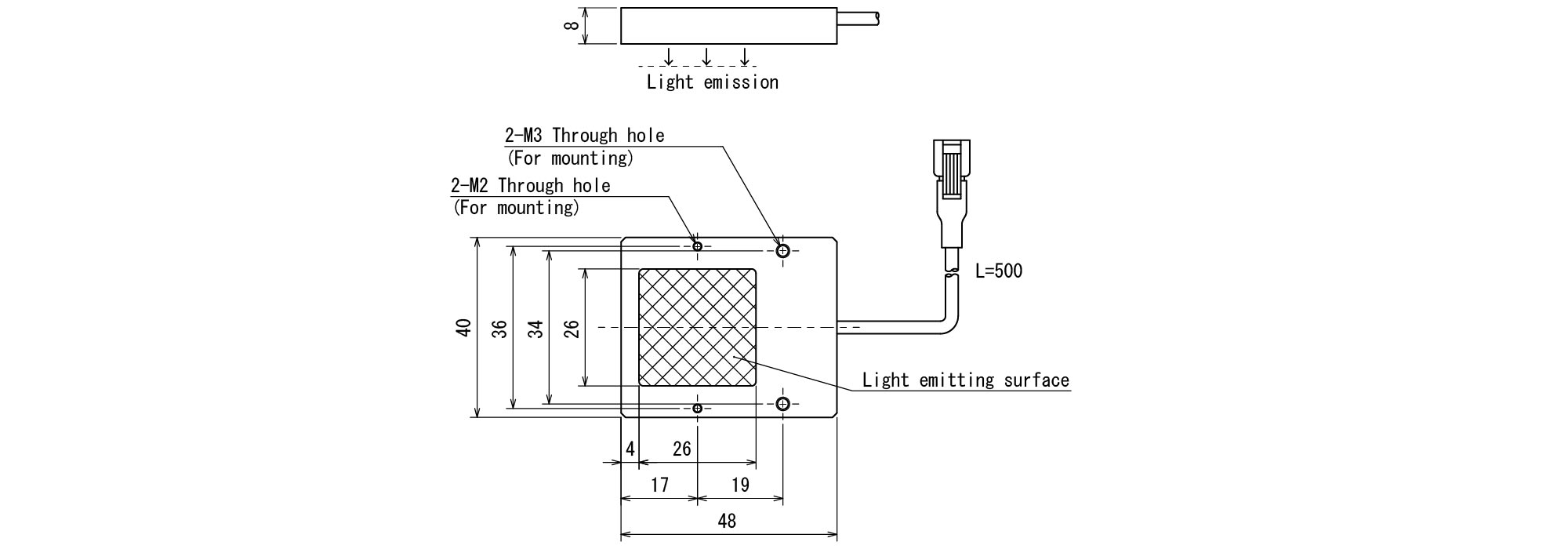

IFVB-20_HV

IFVB-20_HVCoaxial Light – IFVB series

| Model | IFVB-20WHV | IFVB-20RHV | IFVB-20BHV | IFVB-20GHV |

|---|---|---|---|---|

| Product Number | 378-600 | 378-601 | 378-602 | 378-603 |

| Color |  |

|

|

|

| Color temperature/Peak Wavelength | – | 634nm typ. | 465nm typ. | 520nm typ. |

| Input Voltage | DC24V | |||

| Power Consumption | 4.2W | 4W | ||

| Cable Length | 500mm | |||

| Input Connector | SM connector(SMR-03V-B) | |||

| Polarity | 1:+ 2:NC 3:- | |||

| Operating Temperature | 0~+40℃ | |||

| AOperating Humidity | 35~85% (non condensing) | |||

| Weight | 70g | |||

| Conformity Standard |    IEC62471 IEC62471 |

|||

| Cables | ||||

| Controllers |

Please check the output voltage of the compatible power supply. |

|||

| Options | ||||

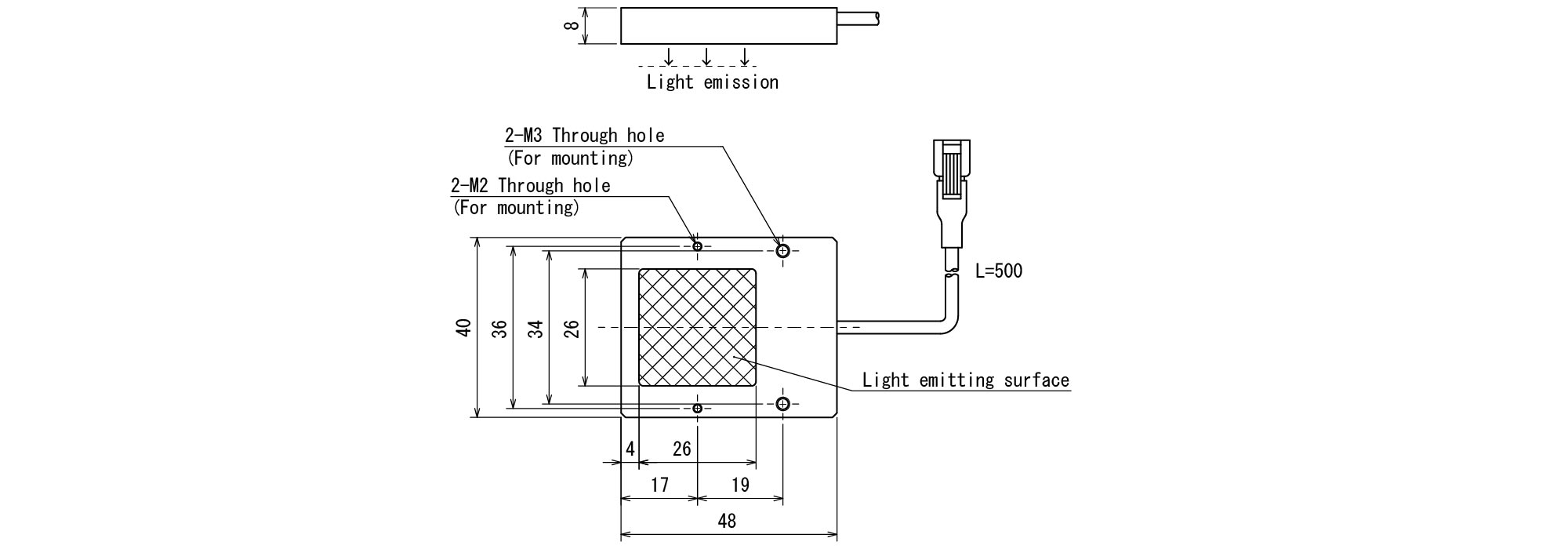

IFVB-20

IFVB-20Coaxial Light – IFVB series

| Model | IFVB-20W | IFVB-20R | IFVB-20B | IFVB-20G |

|---|---|---|---|---|

| Product Number | 378-500 | 378-501 | 378-502 | 378-503 |

| Color |  |

|

|

|

| Color temperature/Peak Wavelength | – | 634nm typ. | 465nm typ. | 520nm typ. |

| Input Voltage | DC12V | |||

| Power Consumption | 4.2W | 4W | ||

| SAG Setting Value | FF | |||

| Cable Length | 500mm | |||

| Input Connector | SM connector(SMR-02V-B) | |||

| Polarity | 1:+ 2:- | |||

| Operating Temperature | 0~+40℃ | |||

| Operating Humidity | 35~85% (non condensing) | |||

| Weight | 70g | |||

| Conformity Standard |    IEC62471 IEC62471 |

|||

| Cables | ||||

| Controllers |

Please check the output voltage of the compatible power supply. |

|||

| Options | ||||

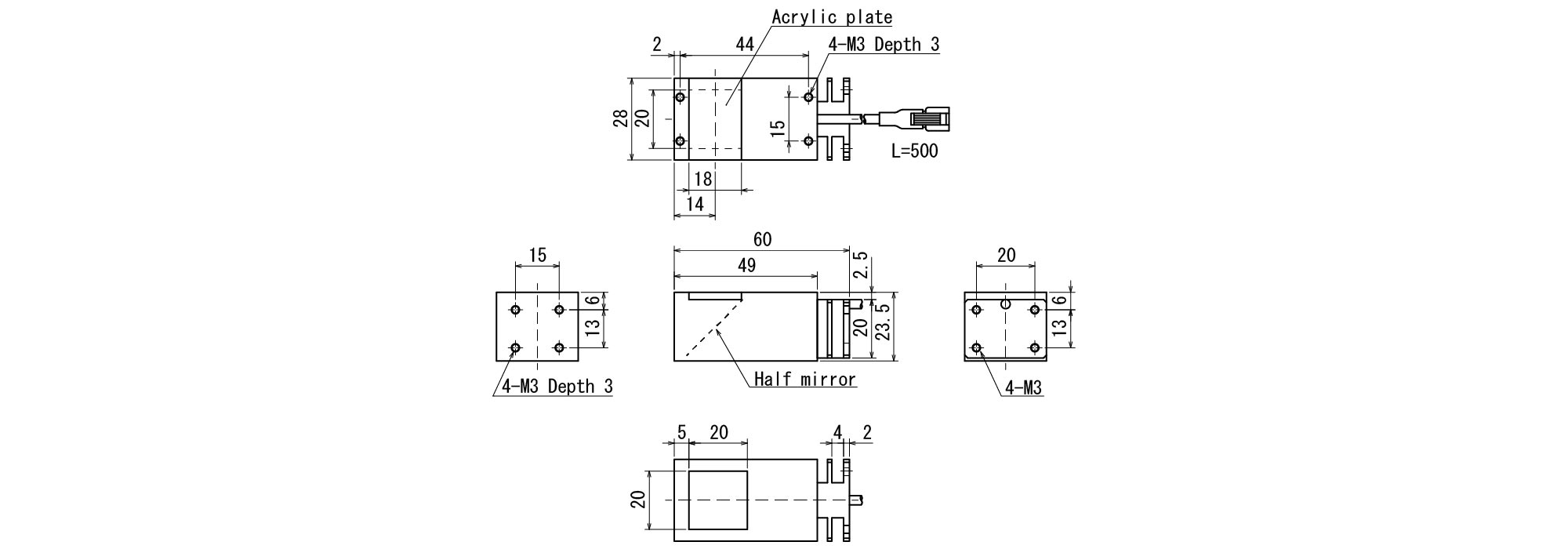

IFVB series

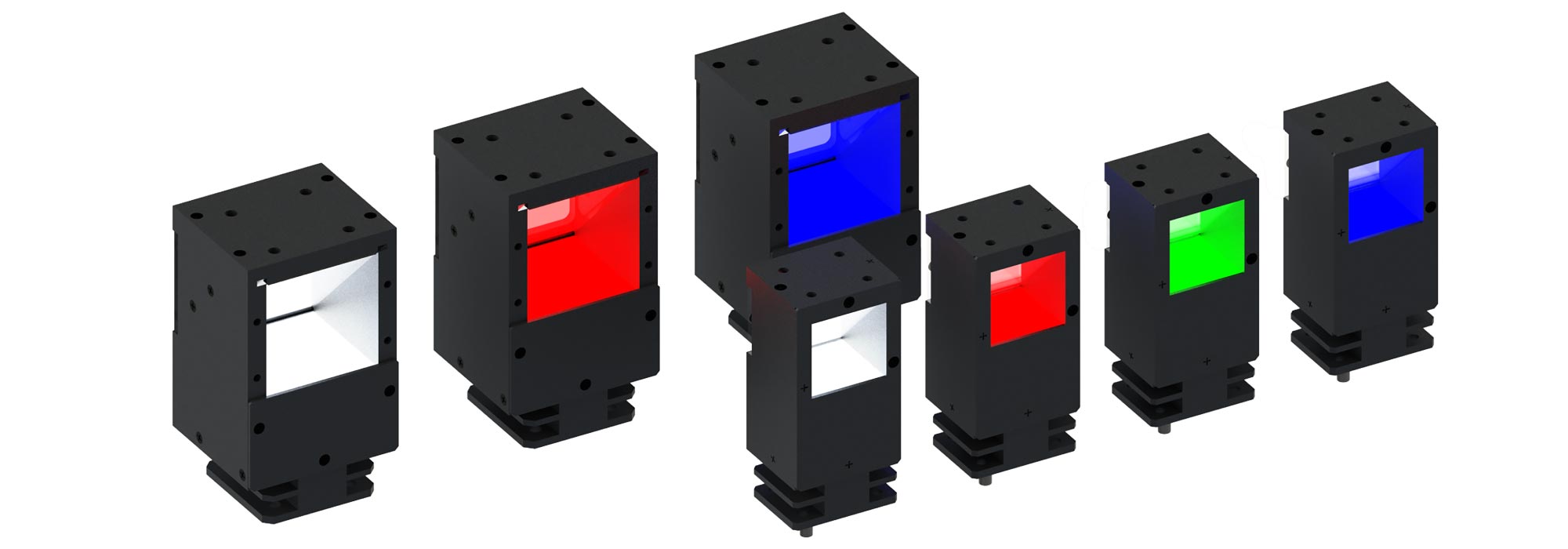

Coaxial LightIFVB series

High illuminance,High uniformity and Compact coaxial Lighting

It is the lighting that can be irradiated with same axis as the camera by using a half mirror.

This is useful for printing / character check and inspection of fine scratches on the surface inspection by a positive reflection.

It is available in a wide range of applications such as pitch measurement of connector pins and pattern inspection of the substrate.

| Model | Input Voltage | Color | Dimensions (W/D/H) |

|---|---|---|---|

| IFVB-20 | DC12V |     |

28mm/60mm/23.5mm |

| IFVB-30 |    |

40mm/70mm/36mm | |

| IFVB-20_HV | DC24V |     |

28mm/60mm/23.5mm |

| IFVB-30_HV |    |

40mm/70mm/36mm |

Improved resolution

Due to the improvement of the half mirror used, the resolution is significantly higher than the old specification IFVA series.

IFHA-25_HV

IFHA-25_HVSquare Dome Light – IFHA series

| Model | IFHA-25RHV | IFHA-25WHV | IFHA-25BHV | IFHA-25GHV |

|---|---|---|---|---|

| Product Number | 357-014 | 357-015 | 357-016 | 357-019 |

| Color |  |

|

|

|

| Color temperature/Peak Wavelength | 630nm typ. | 5000K typ. | 465nm typ. | 520nm typ. |

| Input Voltage | DC24V | |||

| Power Consumption | 2.1W | 2.4W | ||

| Cable Length | 500mm | |||

| Input Connector | SM connector(SMR-03V-B) | |||

| Polarity | 1:+ 2:NC 3:- | |||

| Operating Temperature | 0~+40℃ | |||

| Operating Humidity | 35~85% (non condensing) | |||

| Weight | 40g | |||

| Conformity Standard |  IEC62471 |

|||

| RoHS Directive |  |

|||

| China RoHS |  |

|||

| Cables | ||||

| Controllers |

Please check the output voltage of the compatible controller. |

|||

IFHA-25

IFHA-25Square Dome Light – IFHA series

| Model | IFHA-25R | IFHA-25W | IFHA-25B | IFHA-25G |

|---|---|---|---|---|

| Product Number | 357-010 | 357-011 | 357-012 | 357-018 |

| Color |  |

|

|

|

| Color temperature/Peak Wavelength | 630nm typ. | 5000K typ. | 465nm typ. | 520nm typ. |

| Input Voltage | DC12V | |||

| Power Consumption | 2.1W | 2.4W | ||

| SAG Setting Value | 89 | 83 | 73 | 6F |

| Cable Length | 500mm | |||

| Input Connector | SM connector(SMR-02V-B) | |||

| Polarity | 1:+ 2:- | |||

| Operating Temperature | 0~+40℃ | |||

| Operating Humidity | 35~85% (non condensing) | |||

| Weight | 40g | |||

| Conformity Standard |  IEC62471 |

|||

| RoHS Directive |  |

|||

| China RoHS |  |

|||

| Cables | ||||

| Controllers |

Please check the output voltage of the compatible controller. |

|||

IDMU-OP-PI

IDMU-OP-PIParallel communication unit – IDMU series

| Model | IDMU-OP-PI |

|---|---|

| Product Number | 448-910 |

| Power input | Supplied from the base unit via the bus connector |

| External control | Parallel communication |

| Variable output value range | According to the connected unit |

| Parallel communication signal voltage | DC+5~+24V |

| Maximum number of control units | 5 Units |

| Maximum number of control channels | 8ch/Unit |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 200g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | BUS CONNECTOR |

| Options |

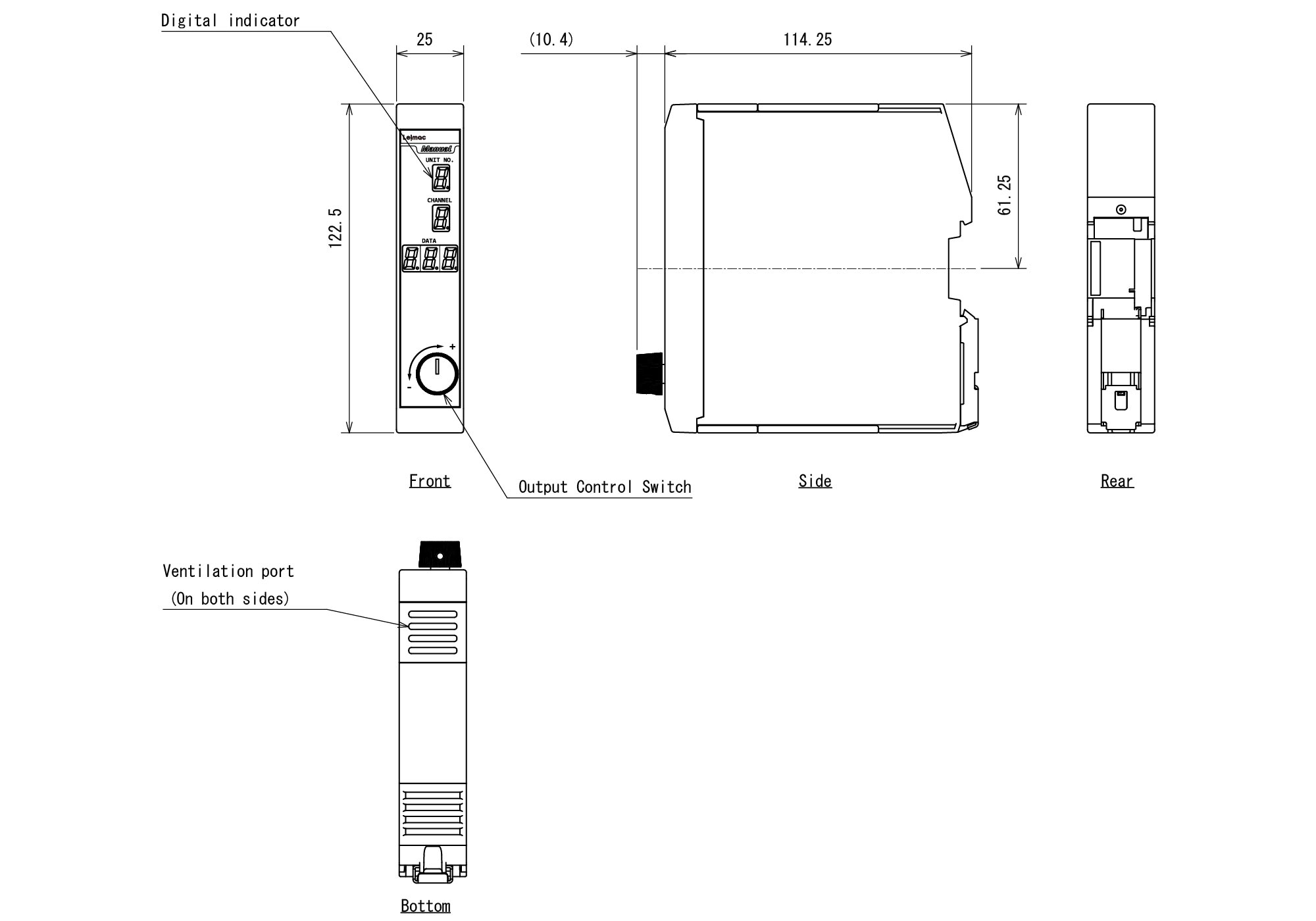

IDMU-OP-M

IDMU-OP-MManual dimming unit – IDMU series

| Model | IDMU-OP-M |

|---|---|

| Product Number | 448-900 |

| Power input | Supplied from the base unit via the bus connector |

| External control | Manual control |

| Variable output value range | According to the connected unit |

| Maximum number of control units | 5 Units |

| Maximum number of control channels | 8ch/Unit |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 200g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | BUS CONNECTOR |

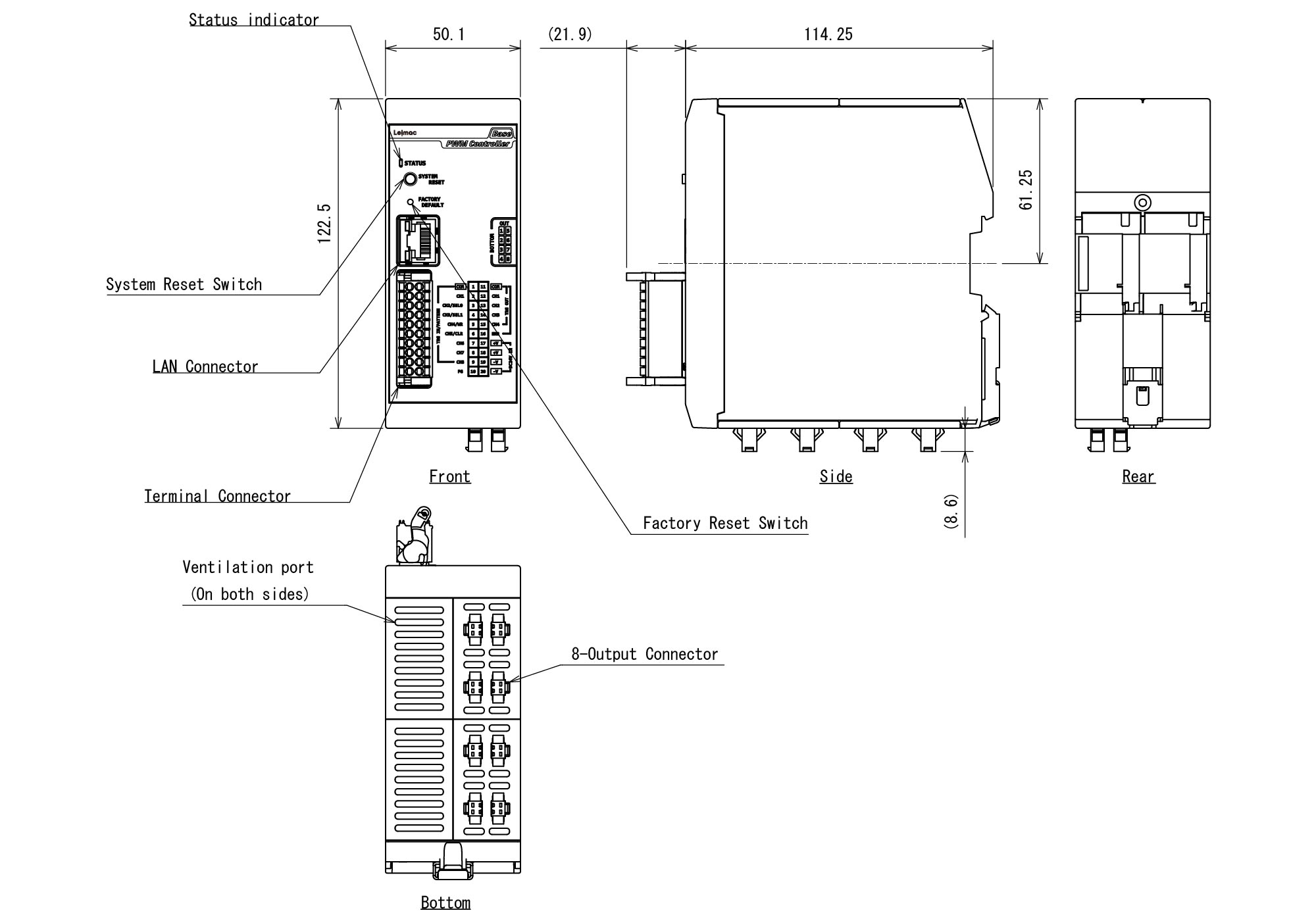

IDMU-P8E-24

IDMU-P8E-24light controller – IDMU series

| Model | IDMU-P8E-24 |

|---|---|

| Product Number | 448-535 |

| Unit Type | Edge |

| Channe numbers | 8ch |

| Output Power | 288W (72W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC24V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Trigger Input | 8ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-03V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 300g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4, 5-6, 7-8])

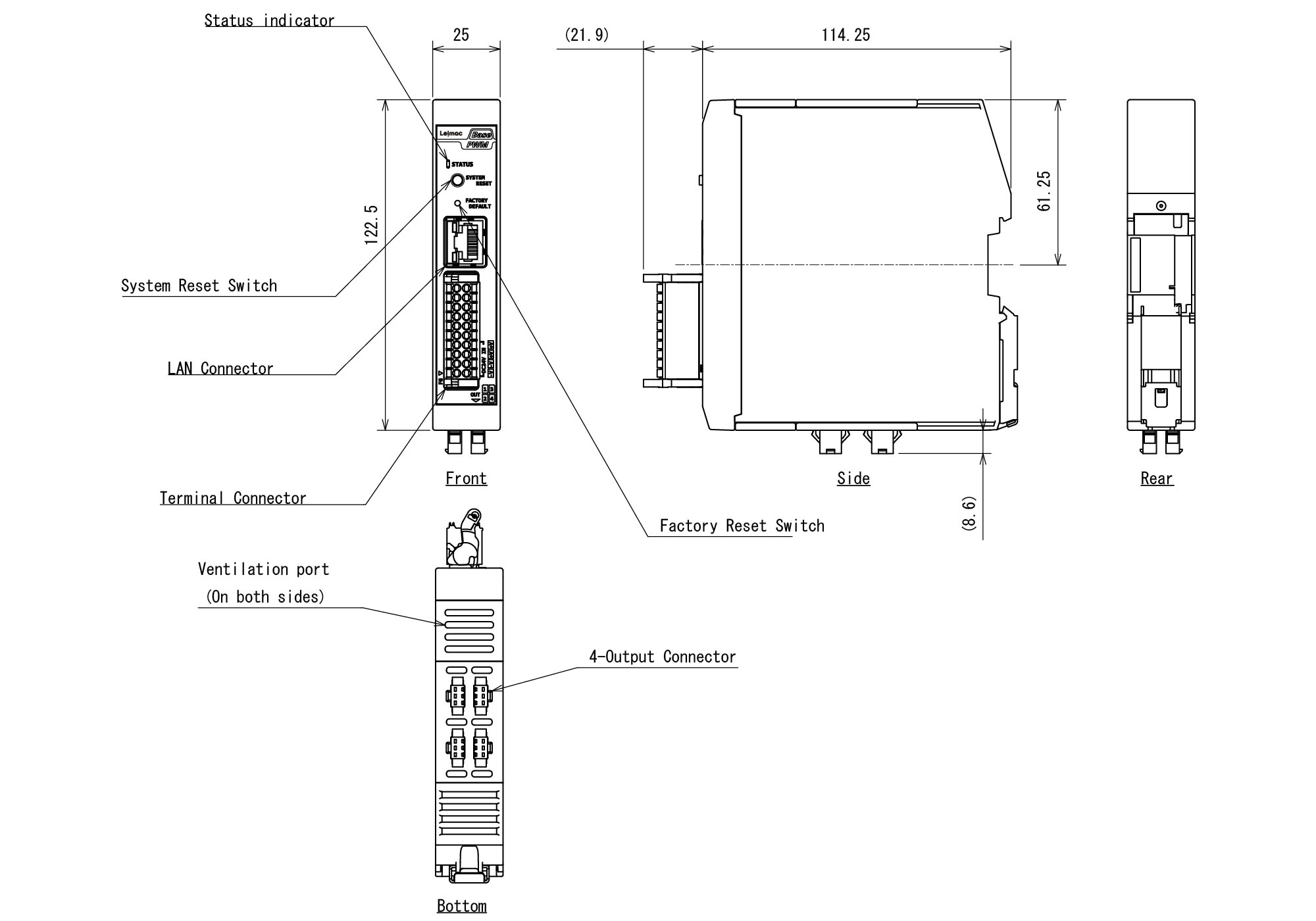

IDMU-P4E-24

IDMU-P4E-24light controller – IDMU series

| Model | IDMU-P4E-24 |

|---|---|

| Product Number | 448-530 |

| Unit Type | Edge |

| Channe numbers | 4ch |

| Output Power | 144W (72W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC24V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Trigger Input | 4ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-03V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 200g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4])

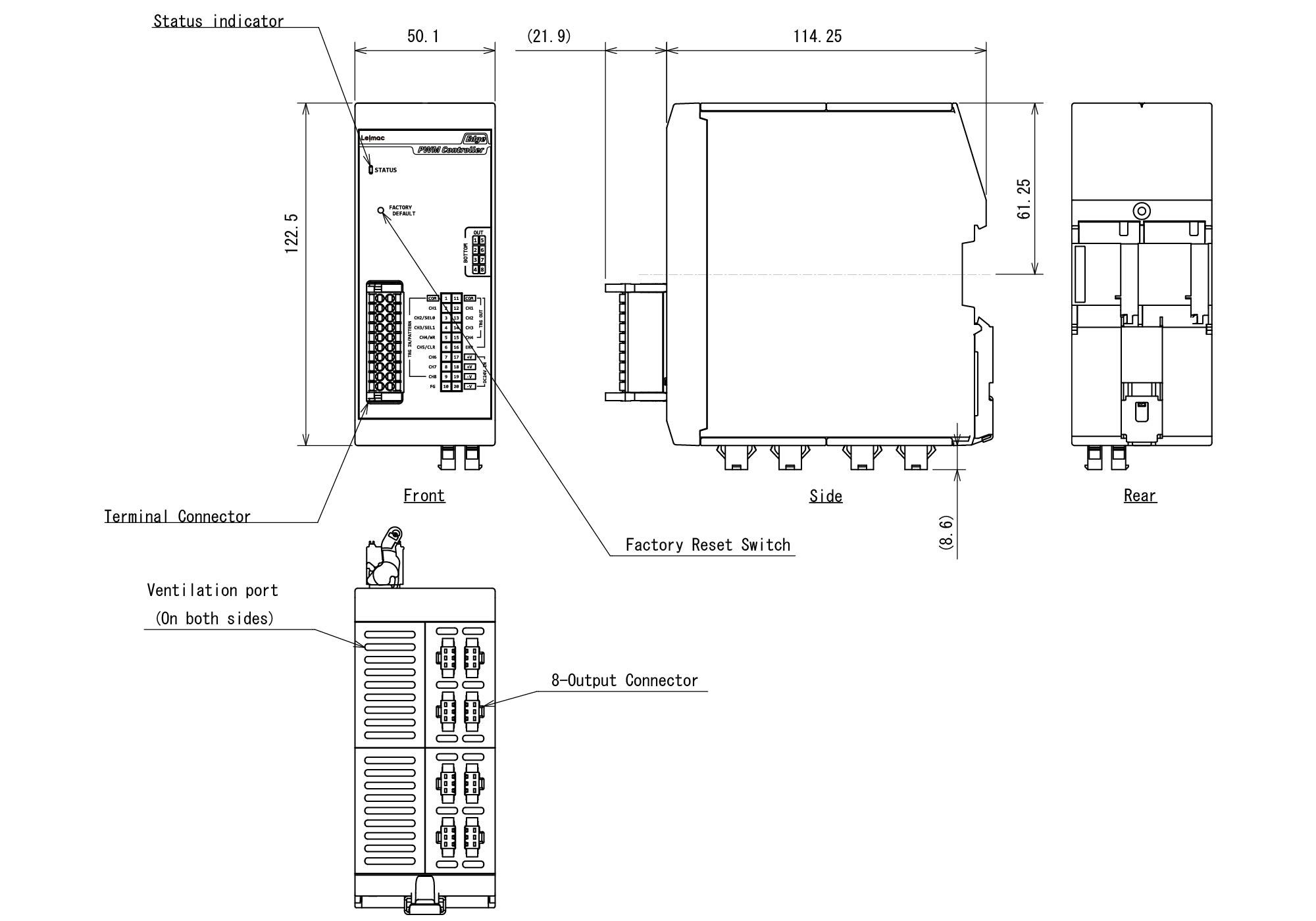

IDMU-P8E-12

IDMU-P8E-12light controller – IDMU series

| Model | IDMU-P8E-12 |

|---|---|

| Product Number | 448-525 |

| Unit Type | Edge |

| Channe numbers | 8ch |

| Output Power | 144W (36W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC12V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Trigger Input | 8ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-02V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 400g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4, 5-6, 7-8])

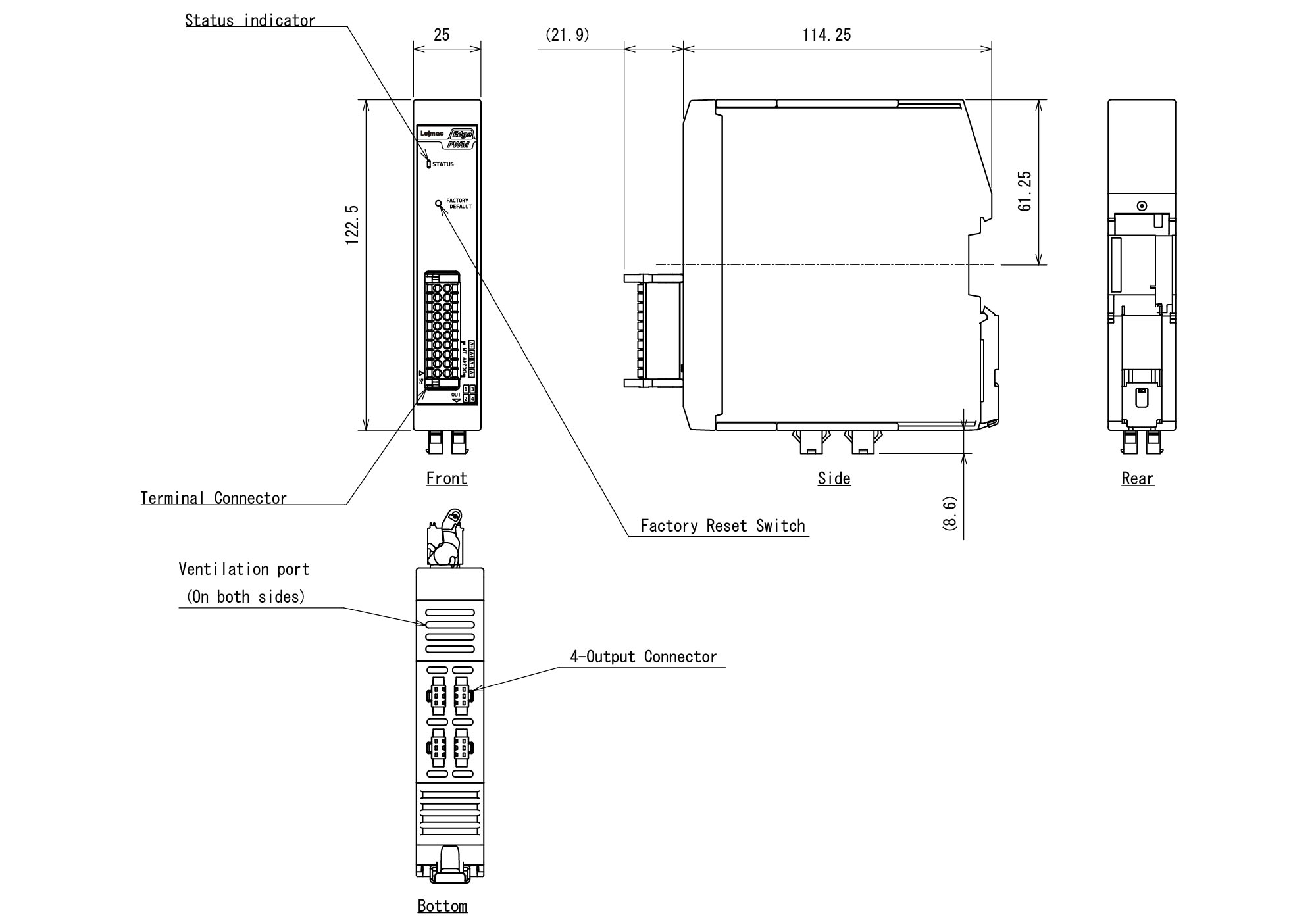

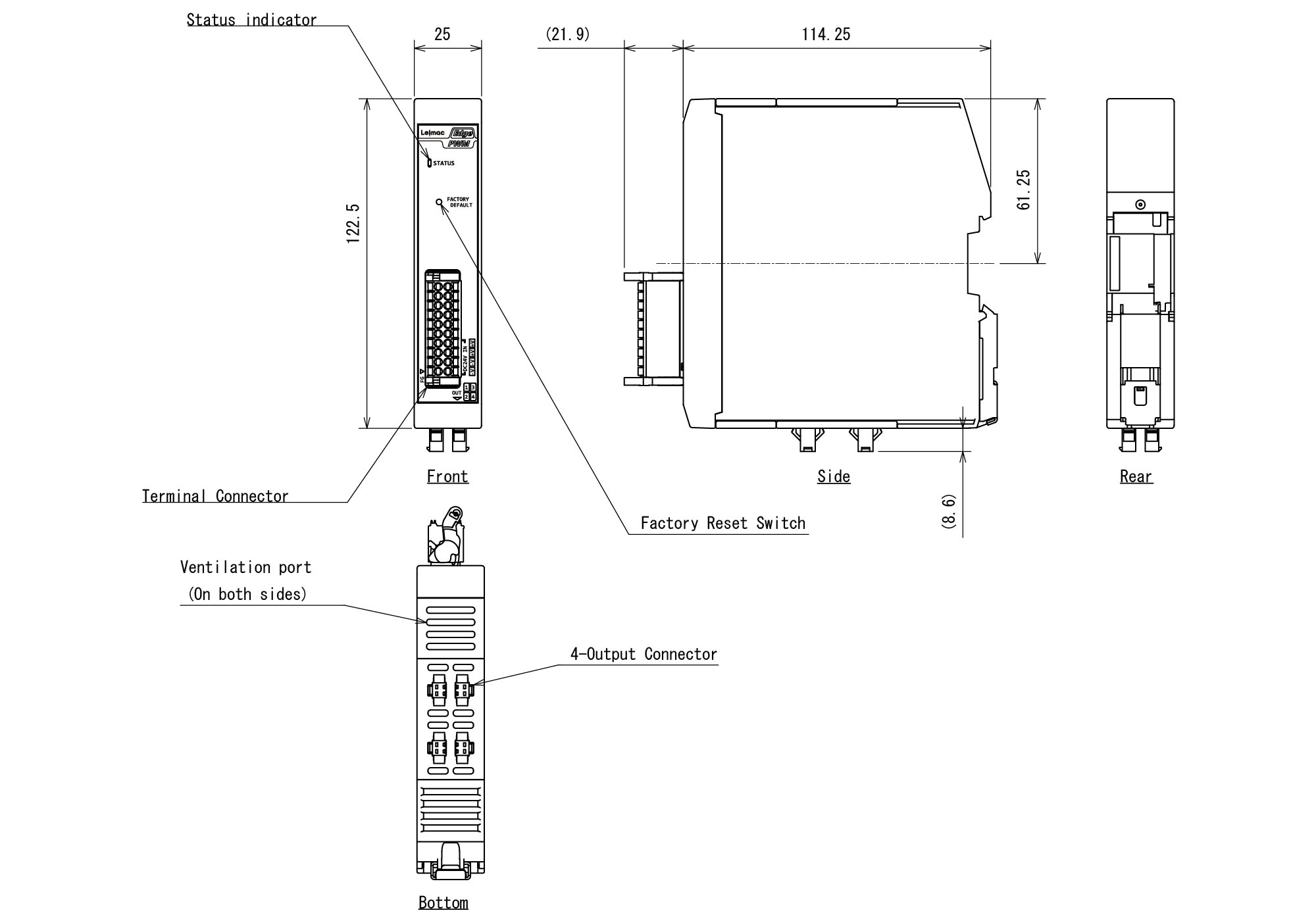

IDMU-P4E-12

IDMU-P4E-12light controller – IDMU series

| Model | IDMU-P4E-12 |

|---|---|

| Product Number | 448-520 |

| Unit Type | Edge |

| Channe numbers | 4ch |

| Output Power | 72W (36W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC12V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Trigger Input | 4ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-02V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 210g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4])

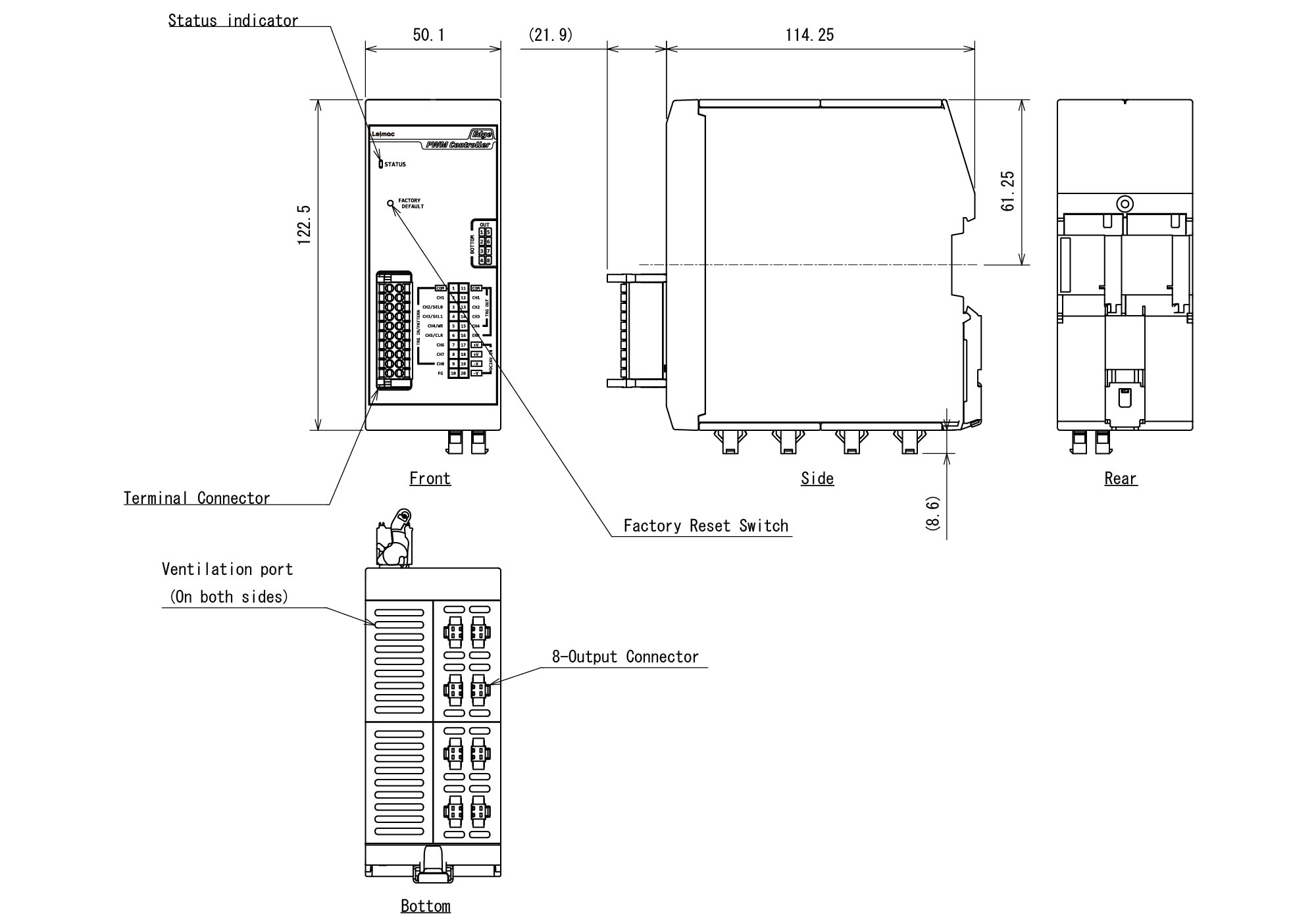

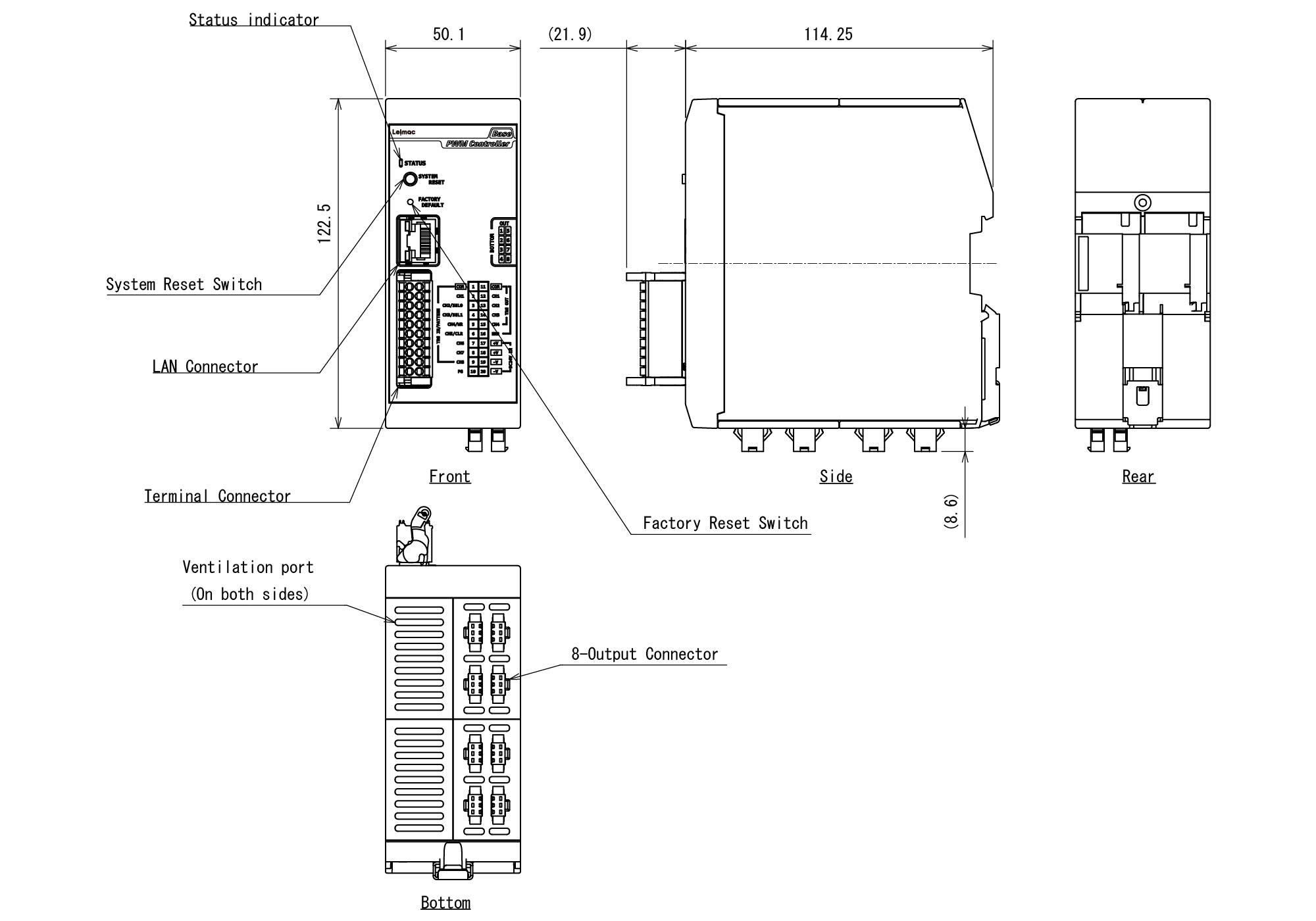

IDMU-P8B-24

IDMU-P8B-24light controller – IDMU series

| Model | IDMU-P8B-24 |

|---|---|

| Product Number | 448-515 |

| Unit Type | Base |

| Channe numbers | 8ch |

| Output Power | 288W (72W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC24V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Control | LAN communication |

| External Trigger Input | 8ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-03V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 300g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

| Options |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4, 5-6, 7-8])

IDMU-P4B-24

IDMU-P4B-24light controller – IDMU series

| Model | IDMU-P4B-24 |

|---|---|

| Product Number | 448-510 |

| Unit Type | Base |

| Channe numbers | 4ch |

| Output Power | 144W (72W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC24V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Control | LAN communication |

| External Trigger Input | 4ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-03V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 200g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

| Options |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4])

IDMU-P8B-12

IDMU-P8B-12light controller – IDMU series

| Model | IDMU-P8B-12 |

|---|---|

| Product Number | 448-505 |

| Unit Type | Base |

| Channe numbers | 8ch |

| Output Power | 144W (36W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC12V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Control | LAN communication |

| External Trigger Input | 8ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-02V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 400g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

| Options |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4, 5-6, 7-8])

IDMU-P4B-12

IDMU-P4B-12light controller – IDMU series

| Model | IDMU-P4B-12 |

|---|---|

| Product Number | 448-500 |

| Unit Type | Base |

| Channe numbers | 4ch |

| Output Power | 72W (36W/2ch ※) |

| Input Voltage | DC24V |

| Output Voltage | DC12V |

| Lighting output adjustment range | Approximately 125kHz PWM, 1000 levels |

| External Control | LAN communication |

| External Trigger Input | 4ch (NPN / PNP supported) |

| External Trigger Output | 4ch (NPN / PNP supported) |

| Communication protocol | Leimac command(TCP/IP、UDP/IP)、GigE Vision(GeniCam support) |

| Other features | < Programming Mode >、DHCP/LLA |

| Output Connector | SM connector(SMP-02V-BC) |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 20~85% (non condensing) |

| Weight | 210g or less |

| Conformity Standard |  (EN55011,EN61000-6-2) |

| RoHS Directive |  |

| China RoHS | |

| Accessories | EXT I/O Connector, BUS CONNECTOR |

| Options |

※ It is the total capacity of 2 channels. (The paired channels are as shown on the right [1-2, 3-4])

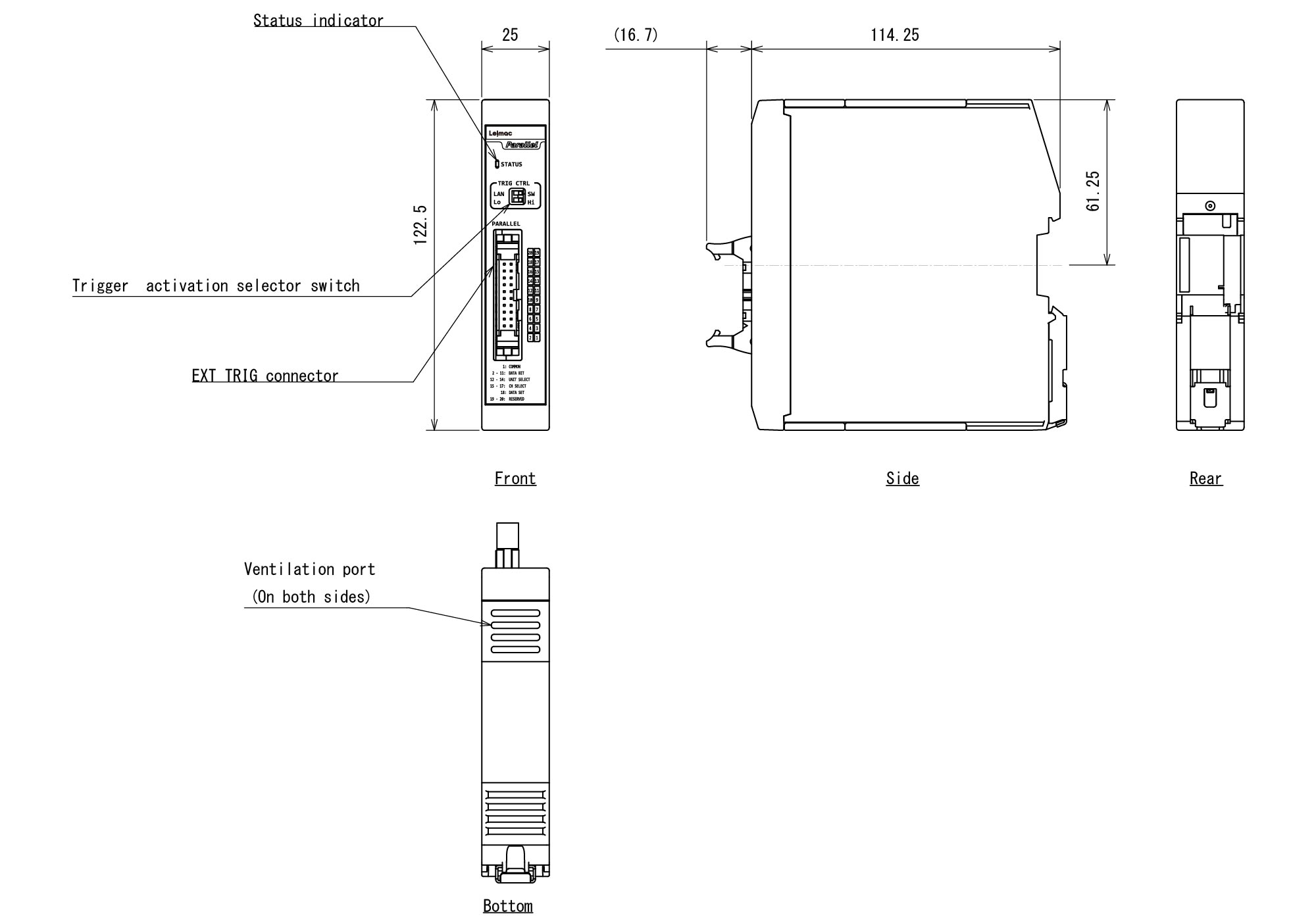

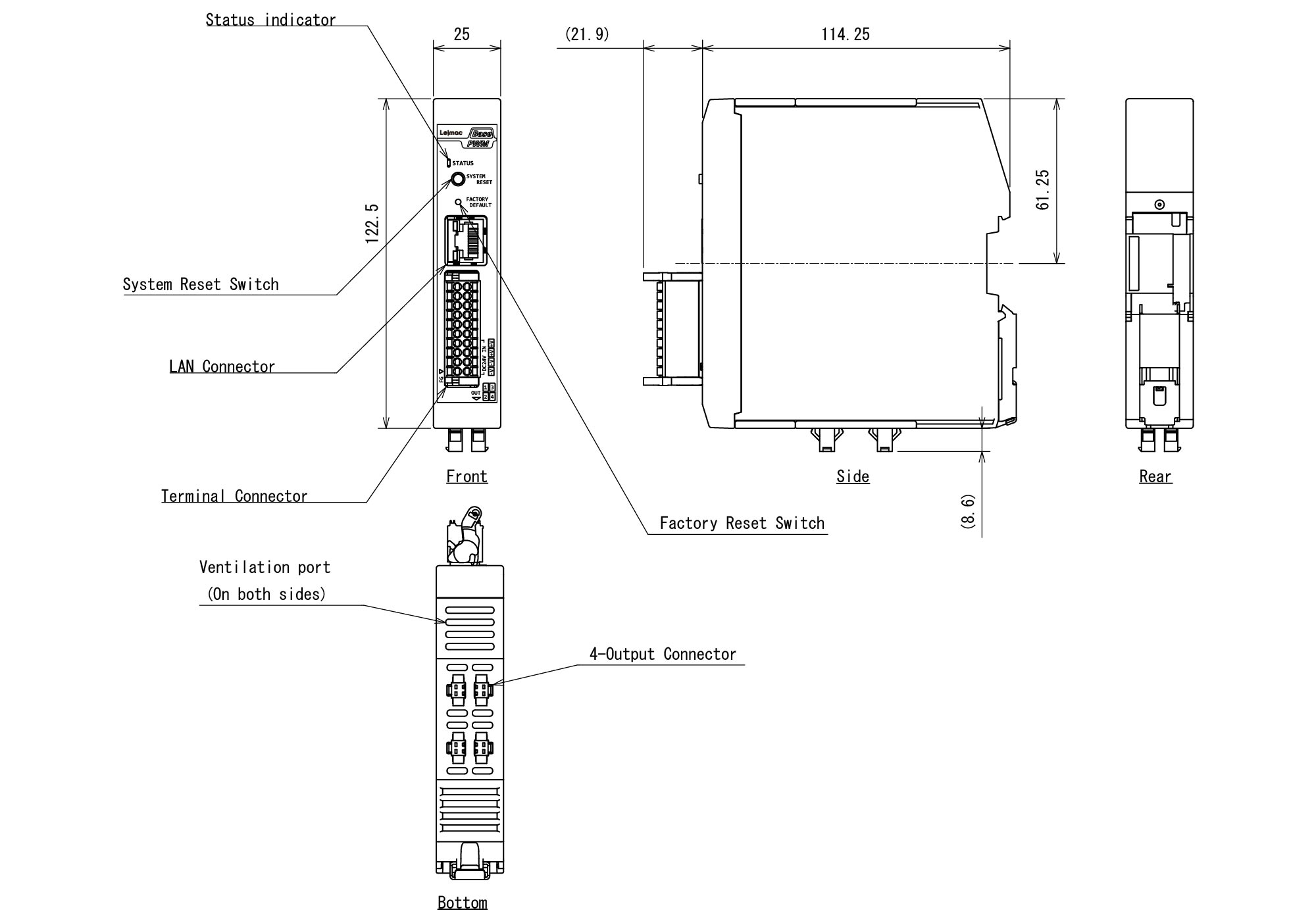

IDMU series

Light controller IDMU series

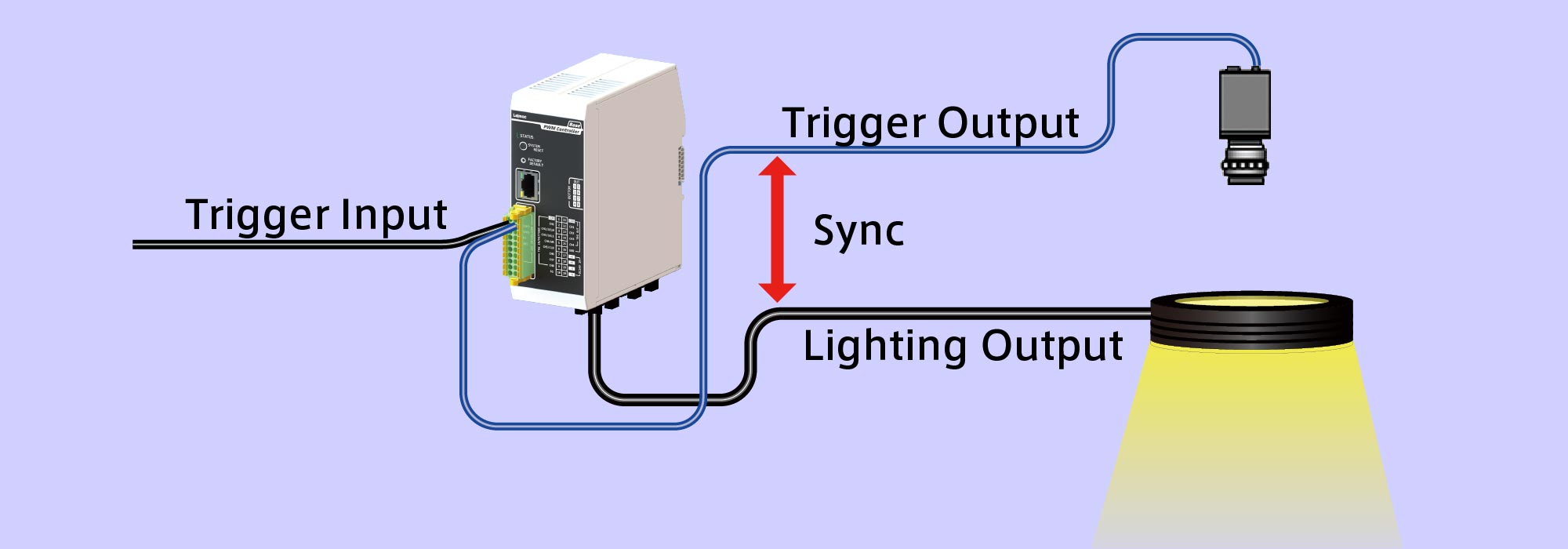

Dimming controller that can input and output trigger signals in both directions

- Optimized image capture timing Synchronous control of lighting on/off, strobe light emission, and trigger output to the camera

- Expandability High flexibility, and up to 40 channels available by connecting units

- Lighting control Lighting ON/OFF controllable by LAN communication

- Wiring-saving Only one LAN cable can control up to 40 channels

- Expanded product lineup The number of channels for both base and edge units is available in 4ch and 8ch specifications, and the output voltage is available in 12V and 24V, which can be connected in individual combinations.

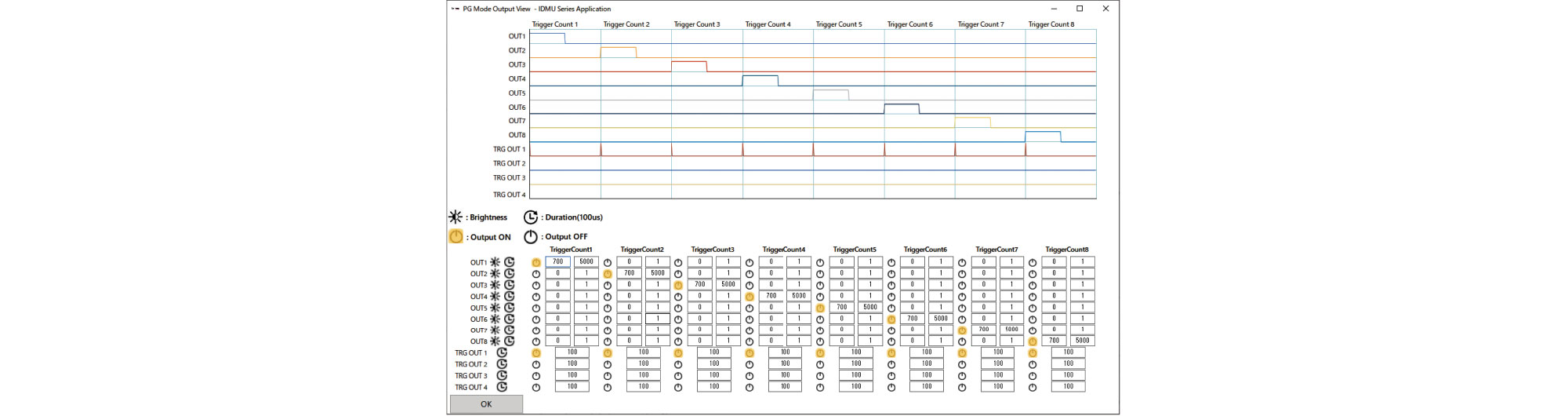

- Programming function Multiple inspection stages can be controlled with a single trigger signal.

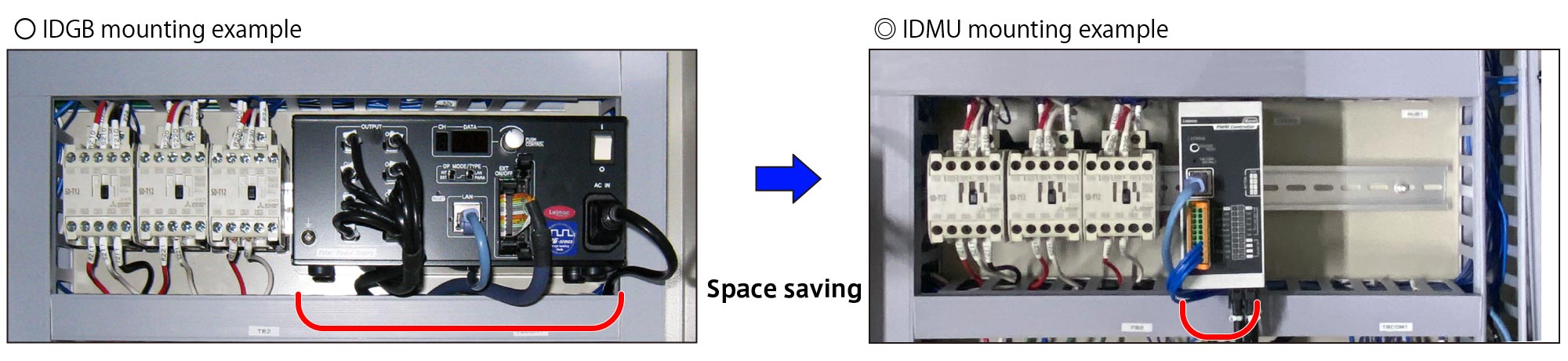

- Space saving DIN rail mounting for control panel integration

- Interface standards GigE Vision and GenICam (Generic Interface for Cameras) supported

Base unit

The basic unit is equipped with LAN communication function as the standard.

It is operated by constant voltage control and outputs using the PWM method.

| Model | Capacity | Channel Number | Input Voltage | Output Voltage | External Control |

|---|---|---|---|---|---|

| IDMU-P4B-12 | 72W | 4CH | DC24V | DC12V | LAN Communication |

| IDMU-P8B-12 | 144W | 8CH | DC24V | DC12V | LAN Communication |

| IDMU-P4B-24 | 144W | 4CH | DC24V | DC24V | LAN Communication |

| IDMU-P8B-24 | 288W | 8CH | DC24V | DC24V | LAN Communication |

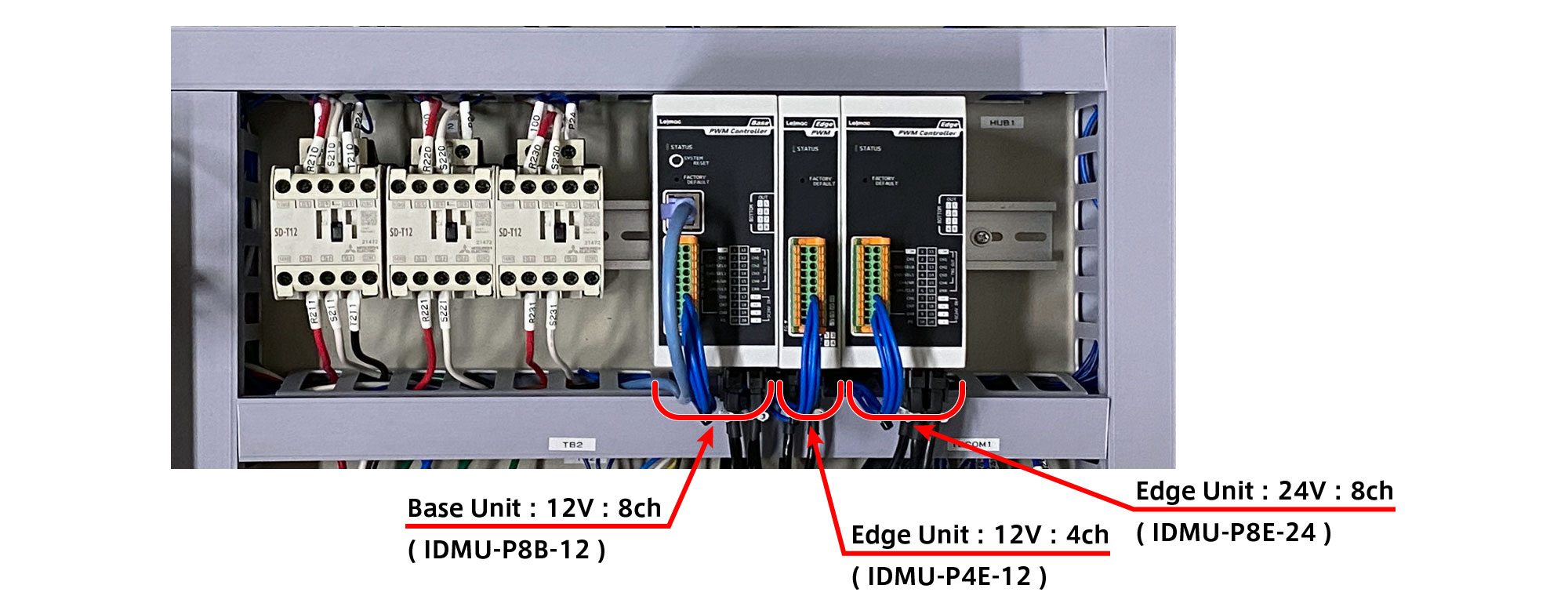

Edge Unit

It is an expansion unit that can be connected to the base unit to increase the number of channels. (The edge unit cannot be operated alone.)

It is operated by constant voltage control and outputs using the PWM method.

| Model | Capacity | Channel Number | Input Voltage | Output Voltage | External Control |

|---|---|---|---|---|---|

| IDMU-P4E-12 | 72W | 4CH | DC24V | DC12V | Via base unit LAN communication |

| IDMU-P8E-12 | 144W | 8CH | DC24V | DC12V | Via base unit LAN communication |

| IDMU-P4E-24 | 144W | 4CH | DC24V | DC24V | Via base unit LAN communication |

| IDMU-P8E-24 | 288W | 8CH | DC24V | DC24V | Via base unit LAN communication |

Optional Unit

It is a control unit that can be connected to the base unit and set by manual dimming or parallel I/O.

| Model | Control Method |

|---|---|

| IDMU-OP-M | Manual dimming |

| IDMU-OP-PI | Parallel communication |

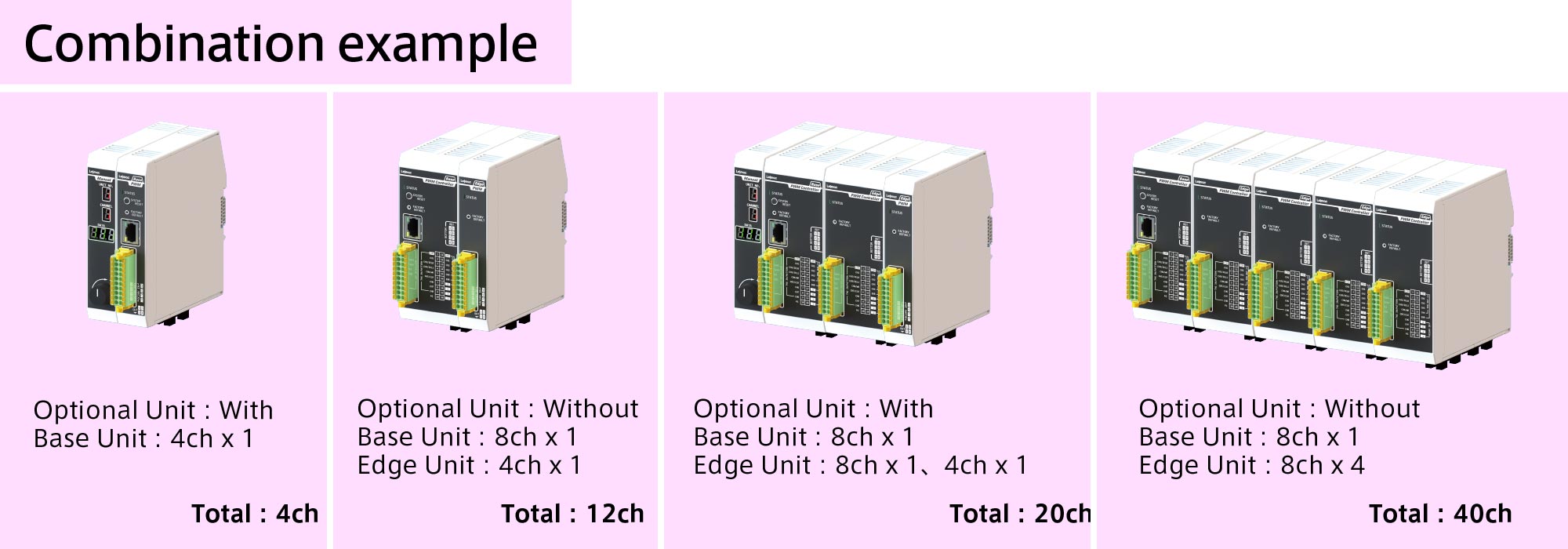

Up to 40 channels with free combination

Able to control up to 40ch at once by combining the base unit (4ch / 8ch) with up to 4 edge units (4ch / 8ch).

Able to mix output voltages of 12V DC output and 24V DC output.

IDMU / IDGB installation comparison

IDMU 12V/24V mixed use example

Programming Mode

It is able to turn on multiple lights in sequence with a single trigger signal.

The programming function allows you to set not only the order, but also the control of output, emission time, delay time, output pattern, external trigger output control, etc., to perform a variety of operations.

External trigger output function allows external synchronization.

It also has a trigger output function in addition to supporting trigger input.

It can synchronize with external devices such as cameras from IDMU.

It can perform image capture and operations in conjunction with lighting connected to the IDMU without preparing an external PLC by combining with the programming function.

GenICam support

In addition to conventional control by command, control by GenICam (SFNC v2.4) is also supported.

GenICam support facilitates operation and enables the reduction of restrictions based on the environment platform during installation and operation.

Various other functions are also supported.

- Lighting ON/OFF control by GenICam control and LAN communication

- DHCP/LLA support (automatic IP address acquisition function)

- GigE Vision support

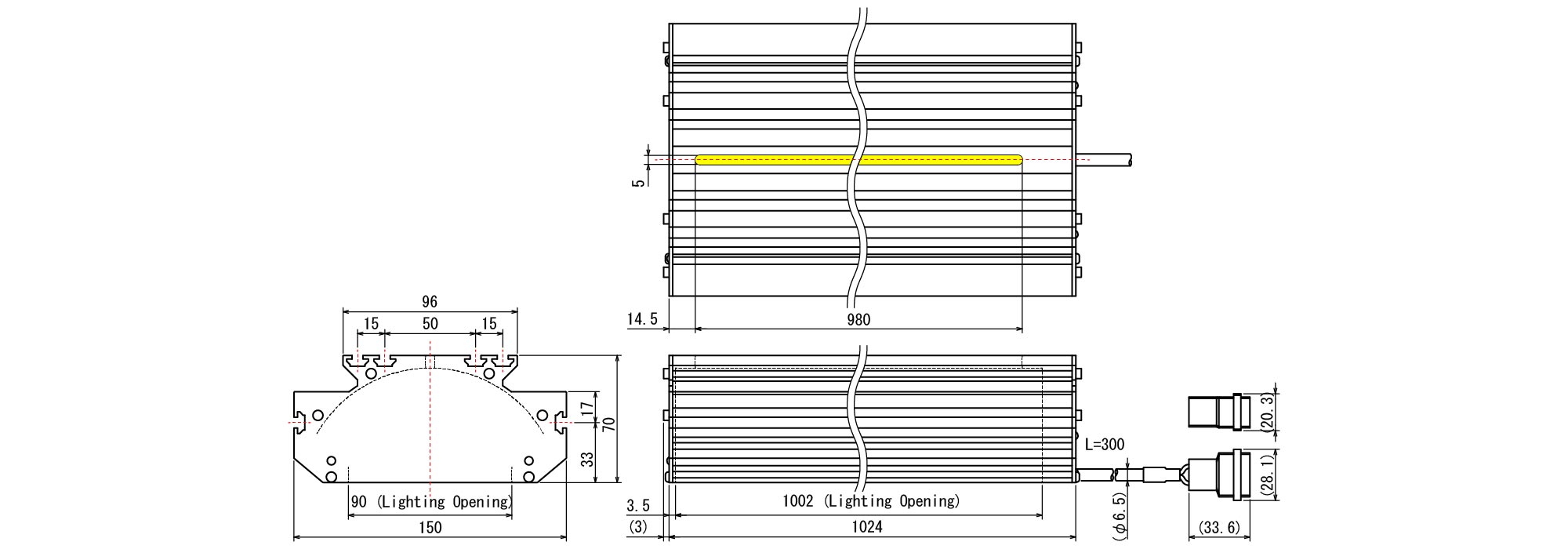

IQDH-RE1000

IQDH-RE1000Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE1000W |

|---|---|

| Product Number | 348-010 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 240W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 4500g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

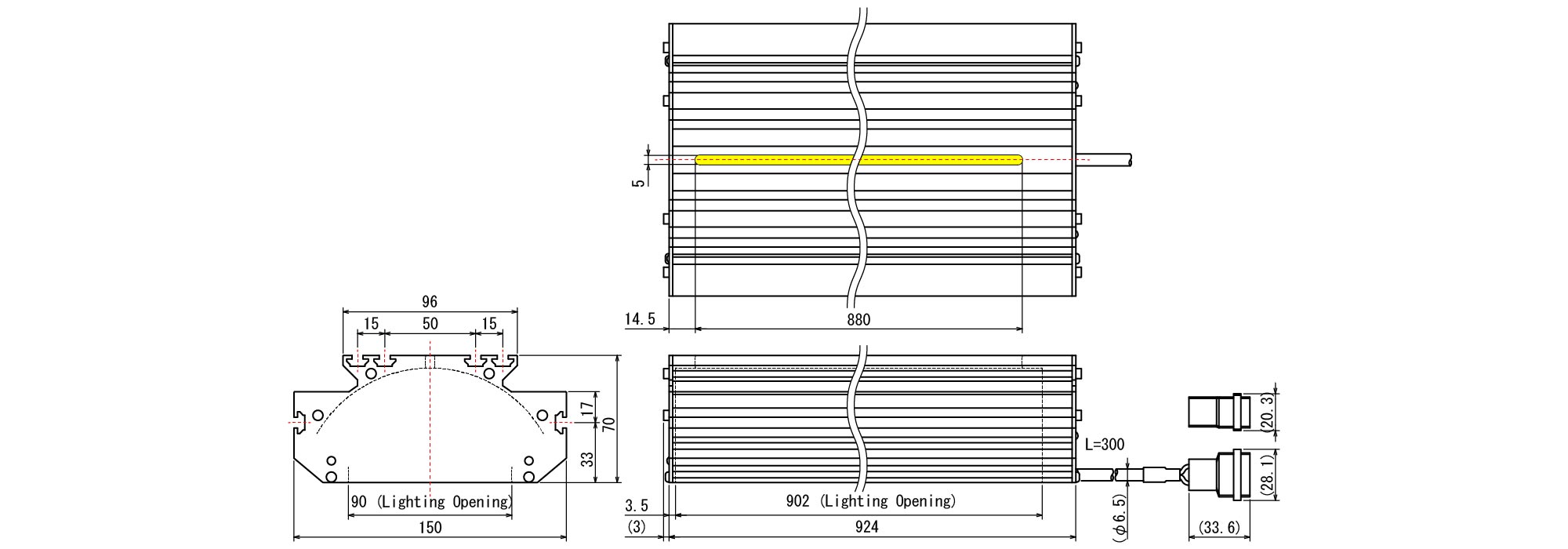

IQDH-RE900

IQDH-RE900Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE900W |

|---|---|

| Product Number | 348-009 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 216W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 4080g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE800

IQDH-RE800Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE800W |

|---|---|

| Product Number | 348-008 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 192W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 3660g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE700

IQDH-RE700Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE700W |

|---|---|

| Product Number | 348-007 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 168W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 3240g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE600

IQDH-RE600Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE600W |

|---|---|

| Product Number | 348-006 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 144W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 2820g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE500

IQDH-RE500Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE500W |

|---|---|

| Product Number | 348-005 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 120W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 2400g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE400

IQDH-RE400Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE400W |

|---|---|

| Product Number | 348-004 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 96W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 1980g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE300

IQDH-RE300Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE300W |

|---|---|

| Product Number | 348-003 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 72W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 1560g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE200

IQDH-RE200Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE200W |

|---|---|

| Product Number | 348-002 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 48W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 1140g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |

IQDH-RE100

IQDH-RE100Half-pipe Light for Line-scan cameras – IQDH-RE series

| Model | IQDH-RE100W |

|---|---|

| Product Number | 348-001 |

| Color |  |

| Color temperature/Peak Wavelength | 5700K typ. |

| Input Voltage | DC48V |

| Power Consumption | 24W |

| Cable Length | 300mm |

| Input Connector | Rectangular type connector |

| Operating Temperature | 0~+40℃ |

| Operating Humidity | 35~85% (non condensing) |

| Weight | 720g |

| Conformity Standard |  IEC62471 |

| RoHS Directive |  |

| China RoHS |  |

| Cables | |

| Controllers |