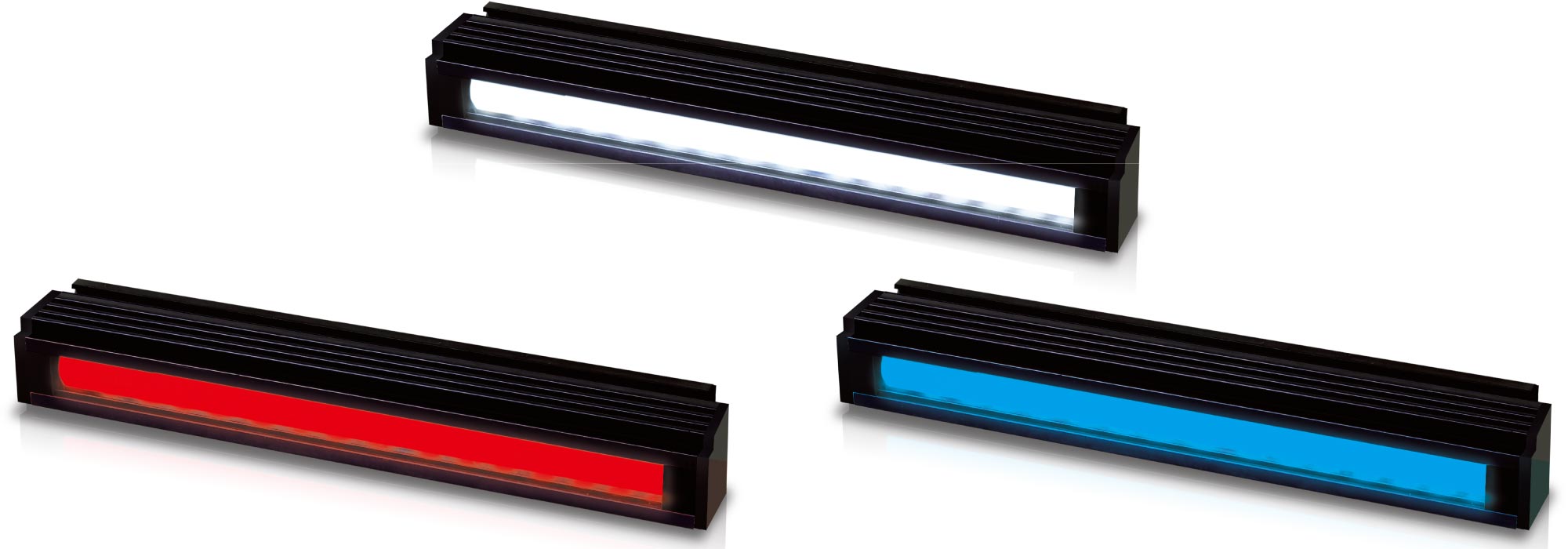

High Power Infrared LightInfrared2 series

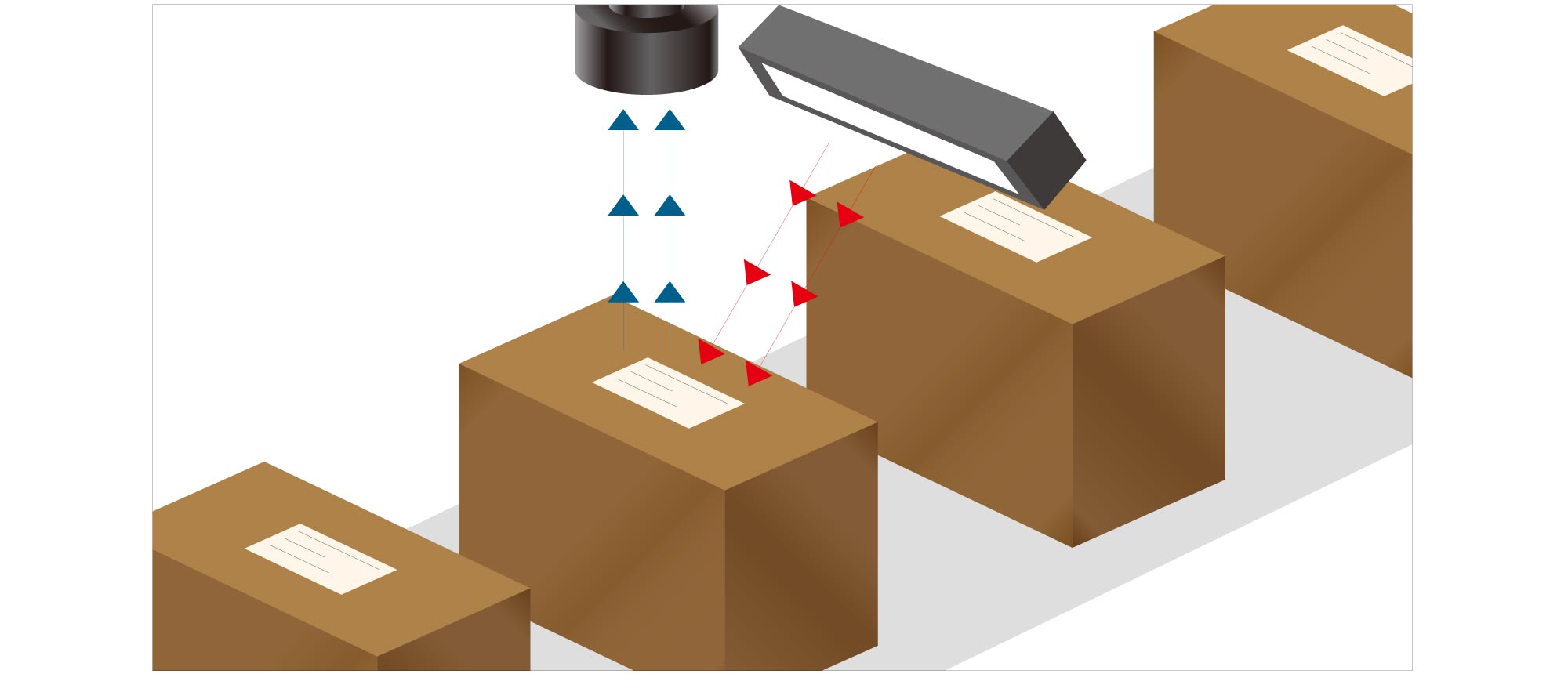

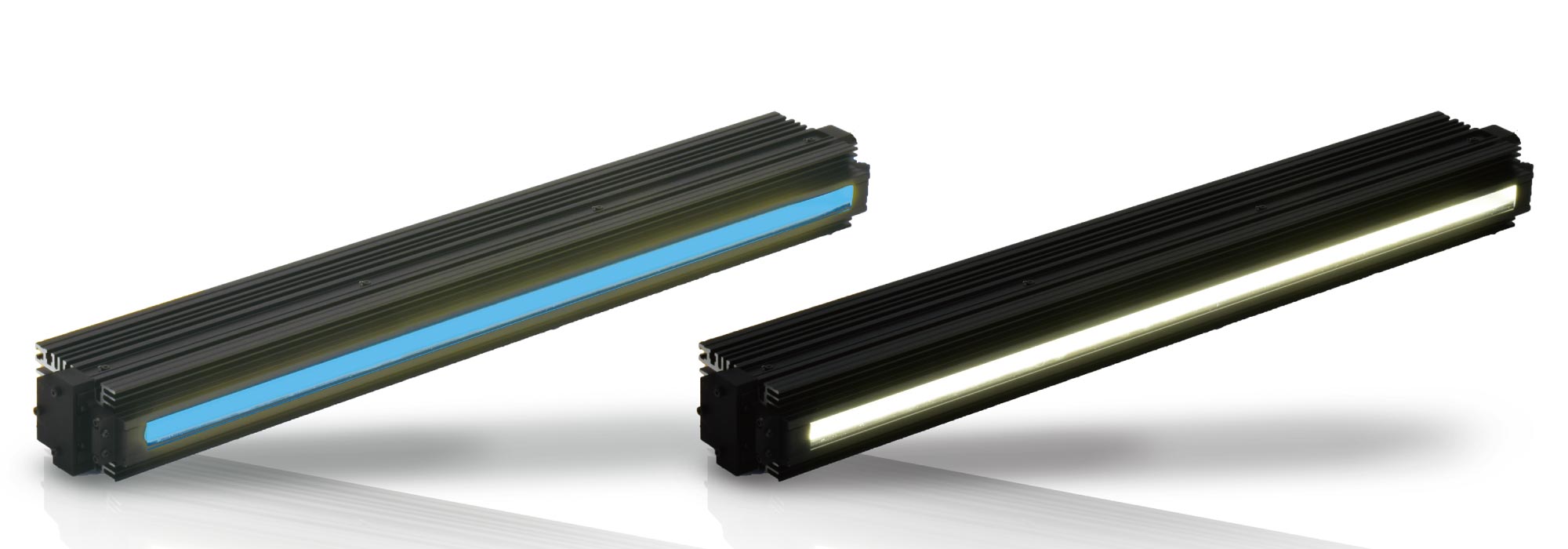

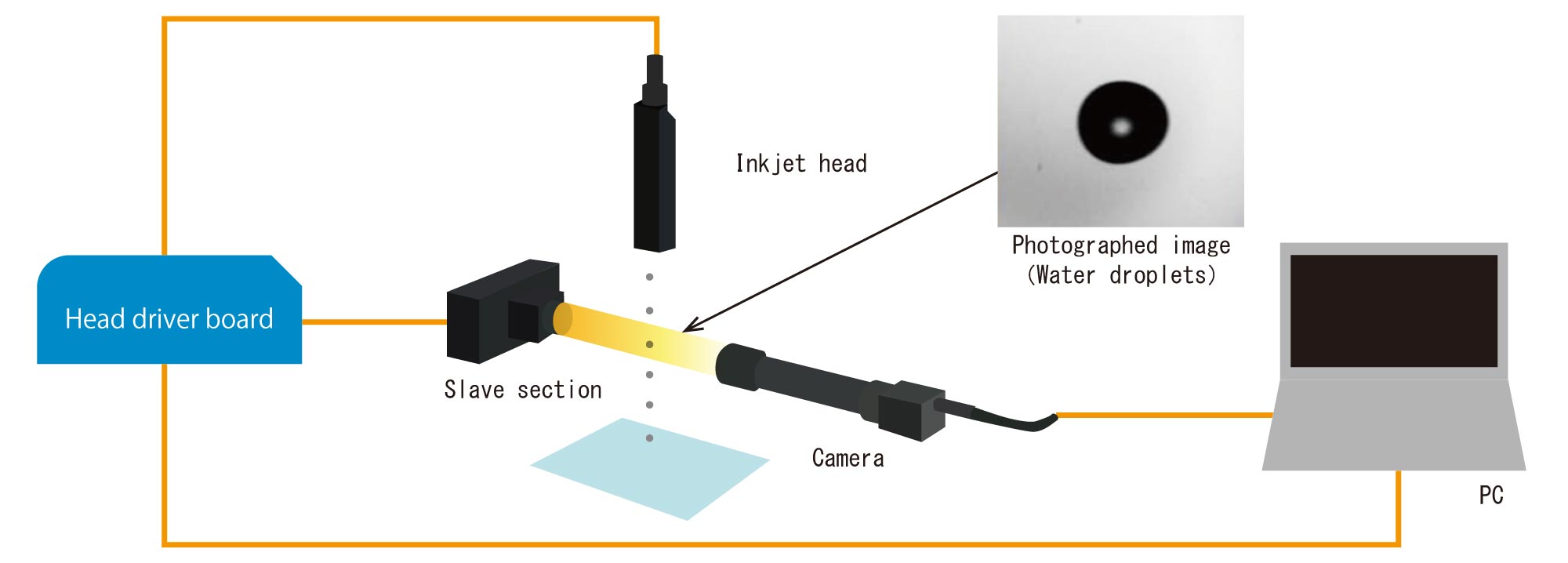

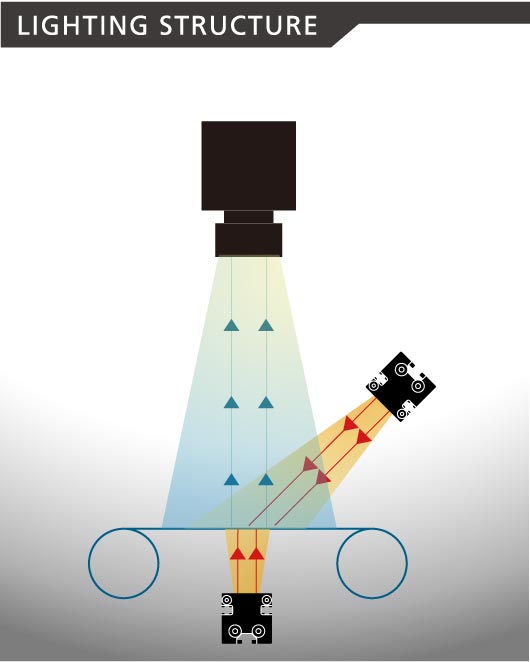

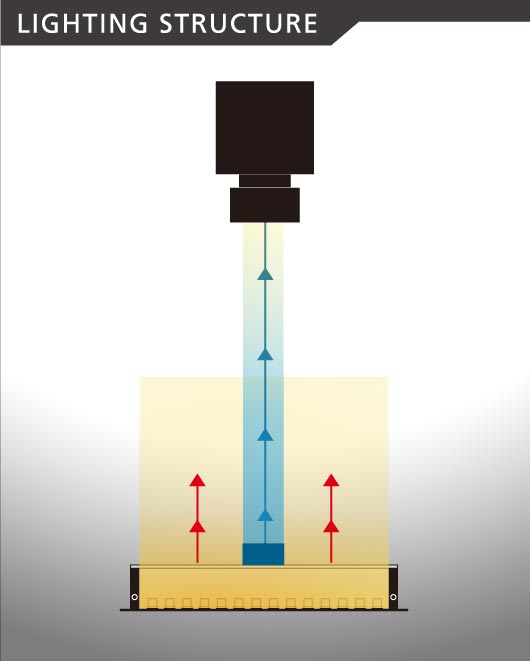

Suitable for transmissive inspection of liquids, and print

Liquid states can be recognized by IR transmission. Text and patterns can also be transmitted to facilitate visual inspection.

Product range includes peak wavelengths excluding 850nm. Other wavelengths not listed in the catalog are also available.

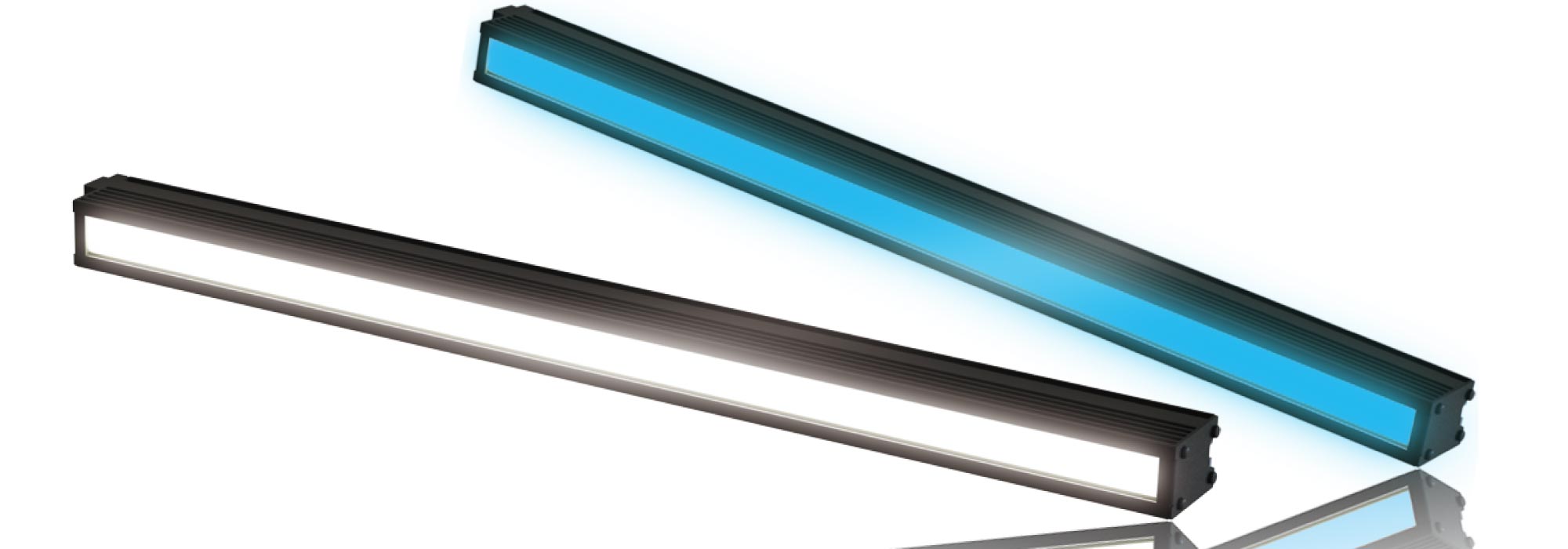

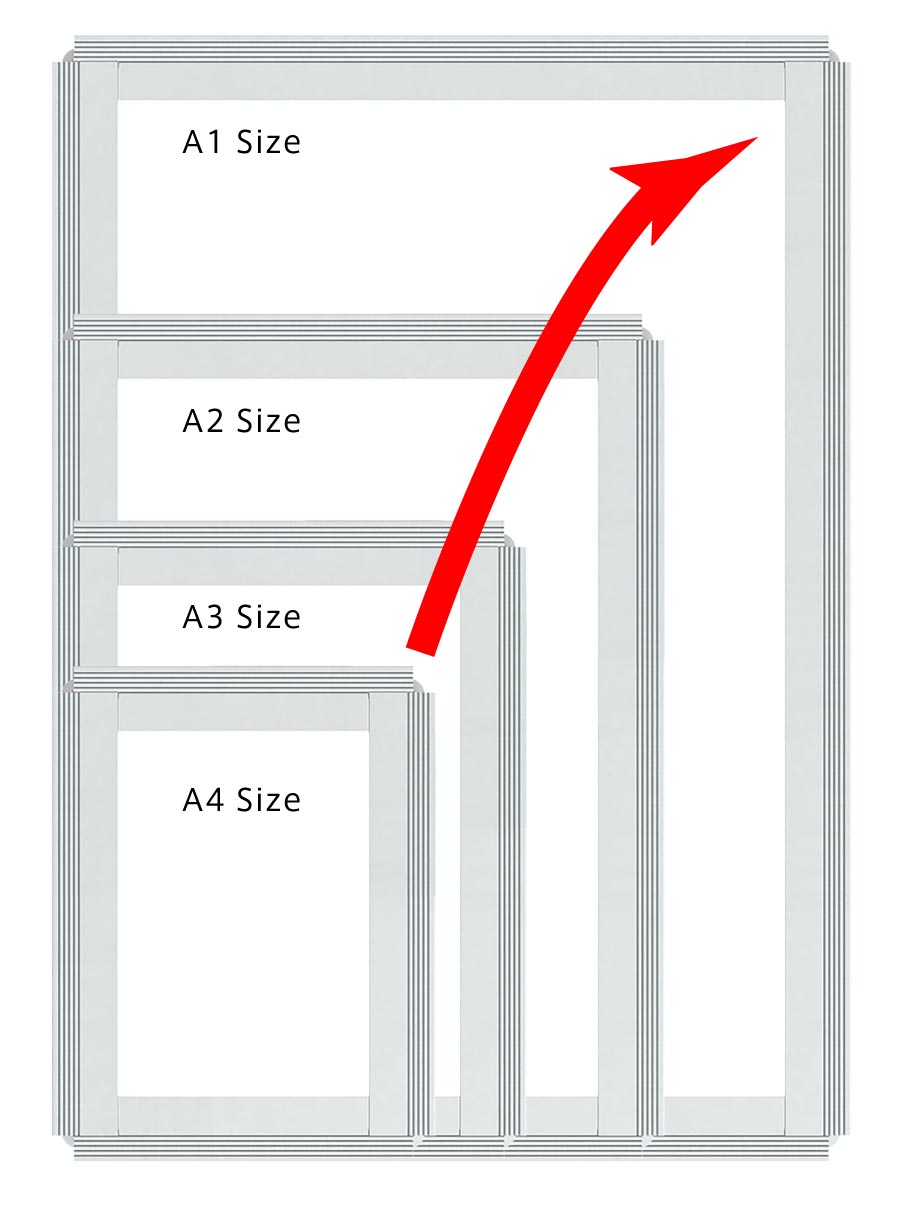

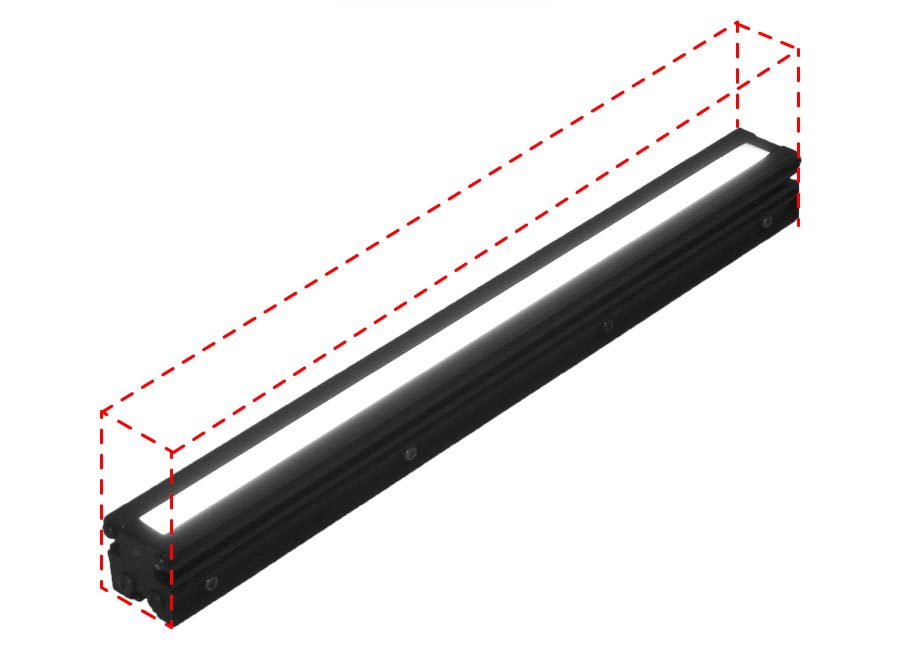

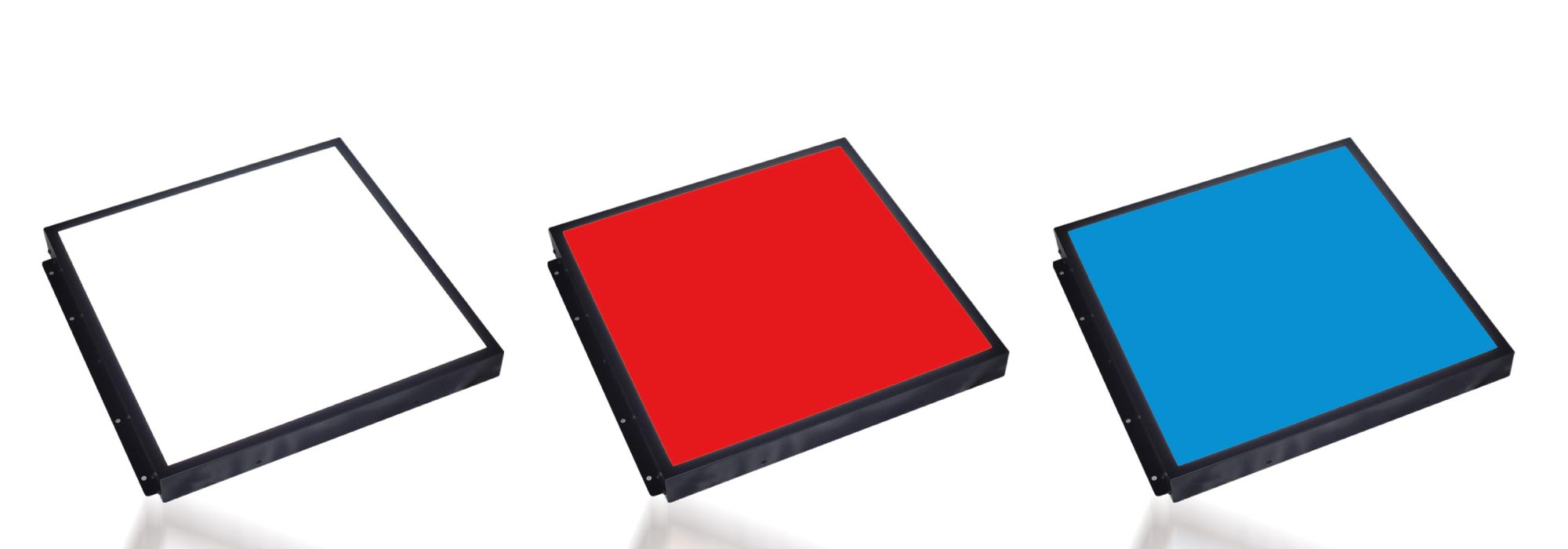

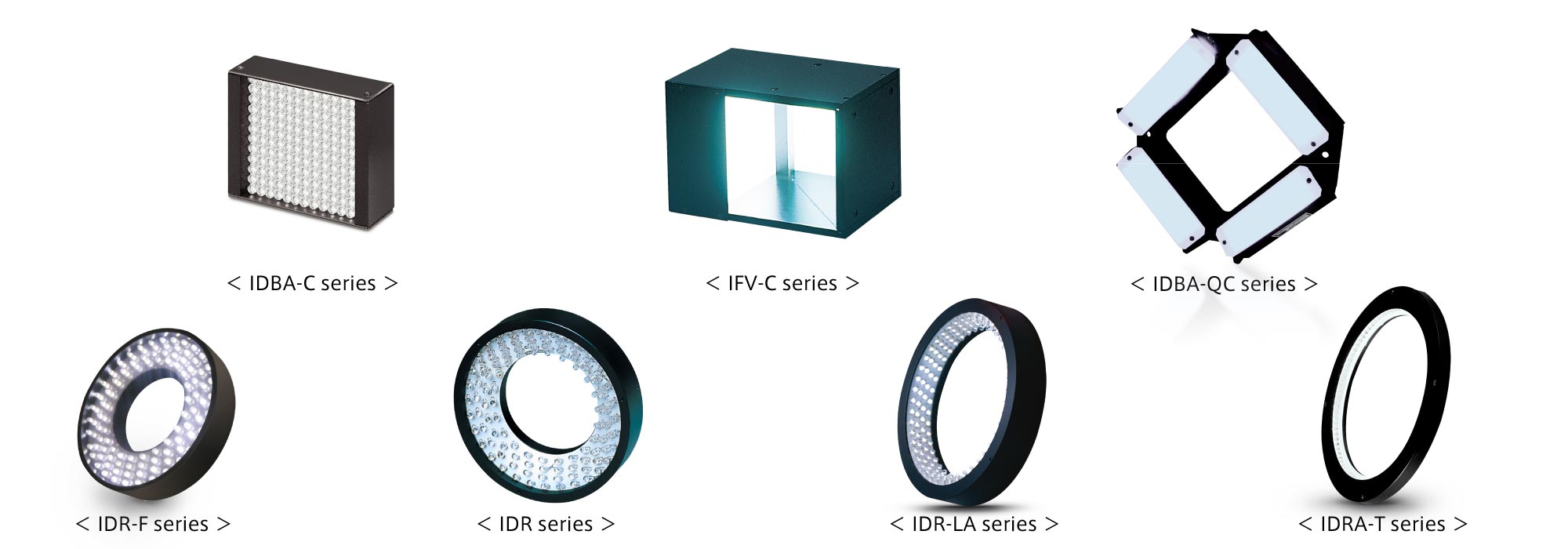

Lighting with the same shape as visible light can be produced.

Please consider the Infrared series as well as the Infrared3 series of long wavelength infrared lighting.

| Model | Input Voltage | Light Type | Peak Wavelength |

|---|---|---|---|

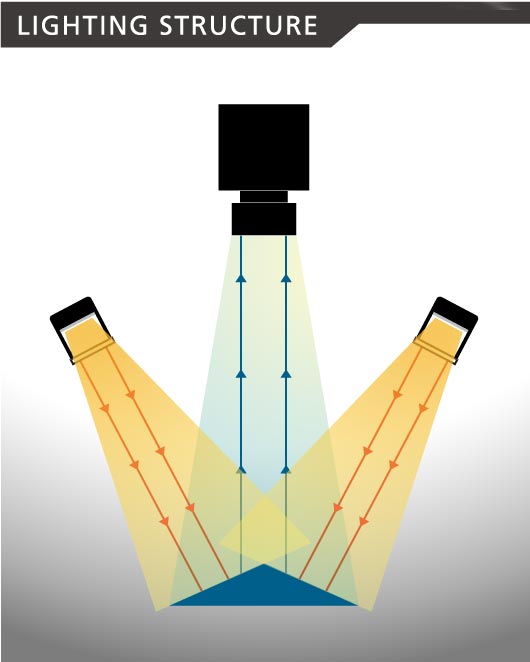

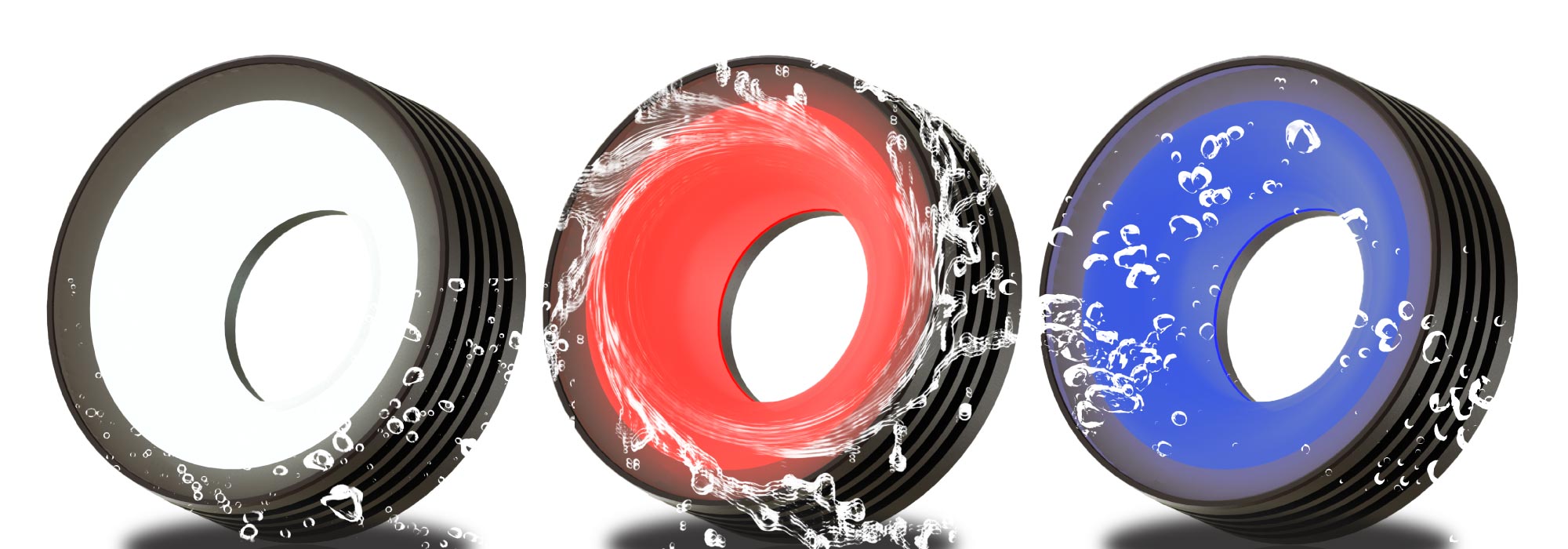

| IMAR-IR series | DC12V/DC24V | Multi-Position Ring Light | 850nm |

| IMAR-CT-IR series | DC12V/DC24V | Multi-Position Ring Light | |

| IHM-25/30IR-850 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-66/60IR-850 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-108/114IR-850 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-150/142IR-850 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-214/226IR-850HV | DC24V | High-Intensity Chip Led Surface Light | |

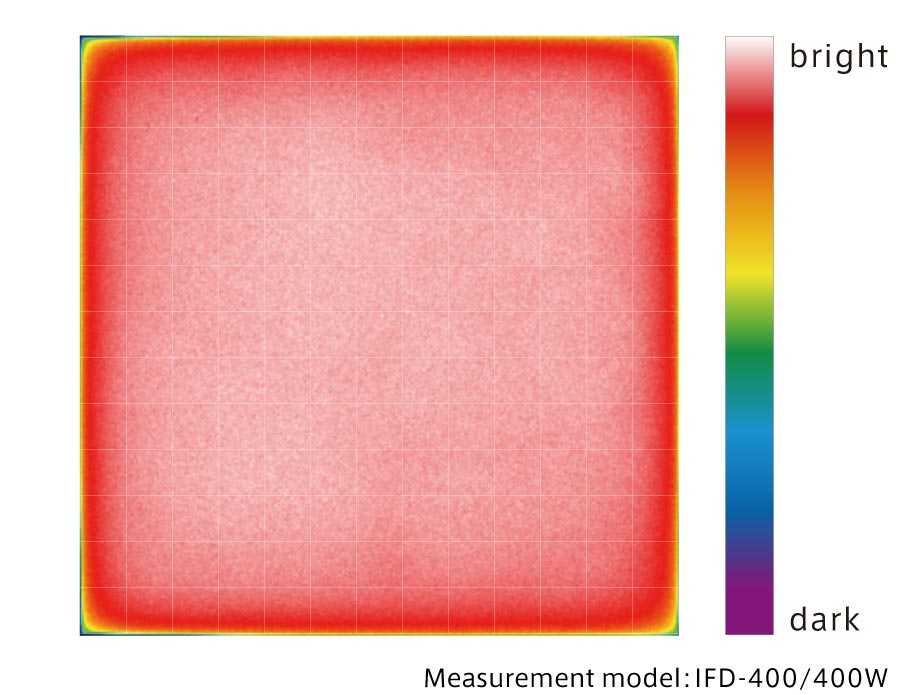

| IFD-200/100IR-850 | DC24V | Large Flat-surface Light | |

| IFD-200/200IR-850 | DC24V | Large Flat-surface Light | |

| IFD-300/100IR-850 | DC24V | Large Flat-surface Light | |

| IFD-300/200IR-850 | DC24V | Large Flat-surface Light | |

| IFD-300/300IR-850 | DC24V | Large Flat-surface Light | |

| IFD-400/100IR-850 | DC24V | Large Flat-surface Light | |

| IFD-400/200IR-850 | DC24V | Large Flat-surface Light | |

| IFD-400/300IR-850 | DC24V | Large Flat-surface Light | |

| IFD-400/400IR-850 | DC24V | Large Flat-surface Light | |

| IFD-500/100IR-850 | DC24V | Large Flat-surface Light | |

| IFD-500/200IR-850 | DC24V | Large Flat-surface Light | |

| IFD-500/300IR-850 | DC24V | Large Flat-surface Light | |

| IFD-500/400IR-850 | DC24V | Large Flat-surface Light | |

| IFD-500/500IR-850 | DC24V | Large Flat-surface Light | |

| IFD-600/100IR-850 | DC24V | Large Flat-surface Light | |

| IFD-600/200IR-850 | DC24V | Large Flat-surface Light | |

| IFD-600/300IR-850 | DC24V | Large Flat-surface Light | |

| IFD-600/400IR-850 | DC24V | Large Flat-surface Light | |

| IFD-600/500IR-850 | DC24V | Large Flat-surface Light | |

| IMAR-IR series | DC12V/DC24V | Multi-Position Ring Light | 950nm |

| IHM-25/30IR-950 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-66/60IR-950 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-108/114IR-950 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-150/142IR-950 | DC12V | High-Intensity Chip Led Surface Light | |

| IHM-214/226IR-950HV | DC24V | High-Intensity Chip Led Surface Light |

*Please consider the Infrared series as well as the Infrared3 series of long wavelength infrared lighting.

| Model | Input Current | Light Type | Peak Wavelength |

|---|---|---|---|

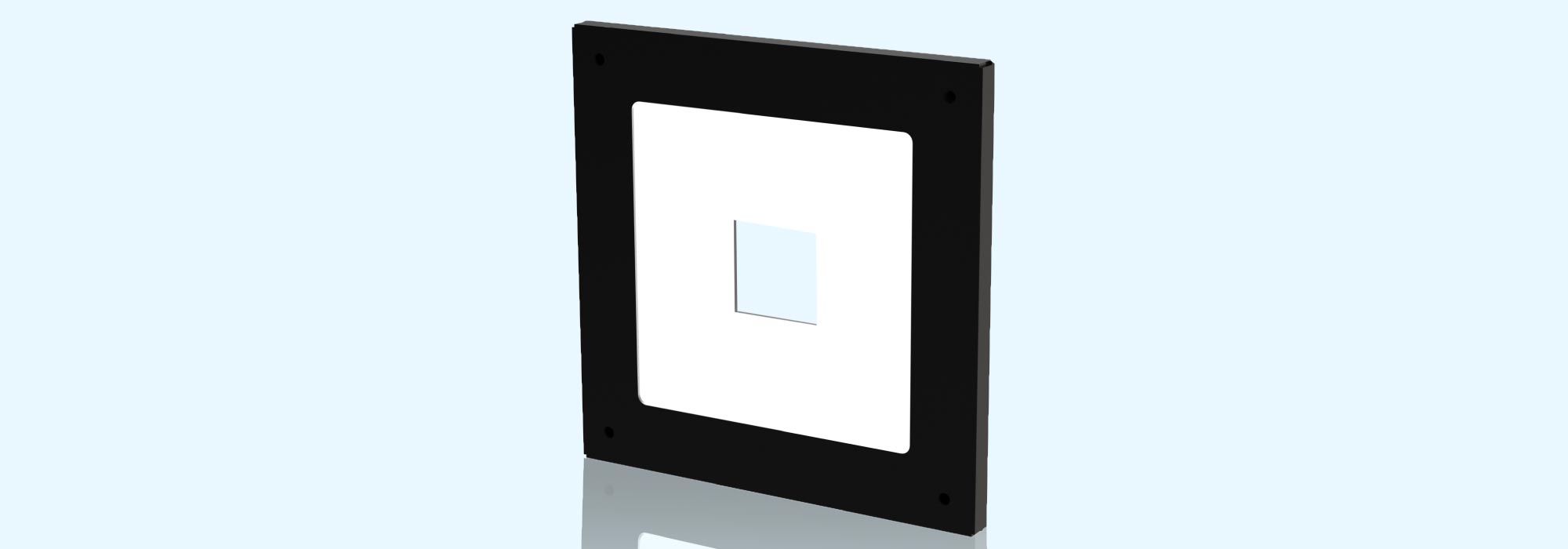

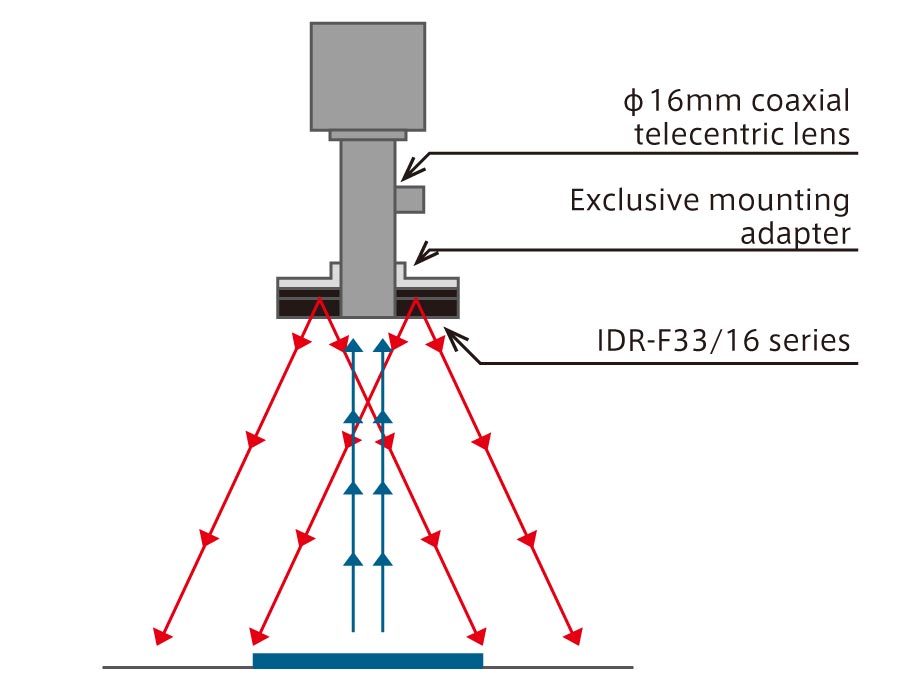

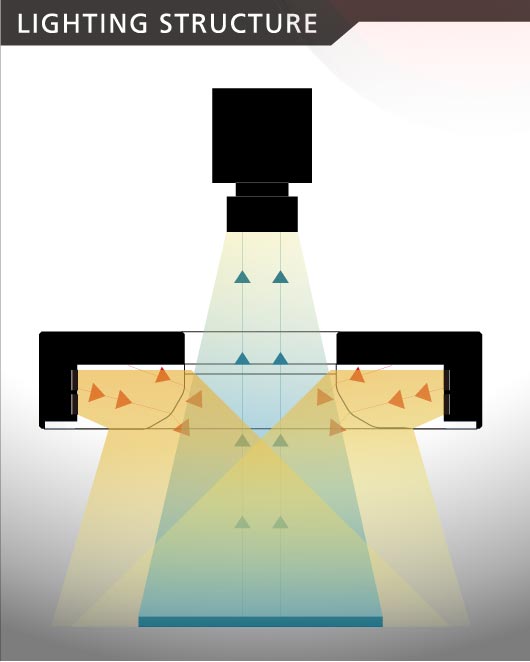

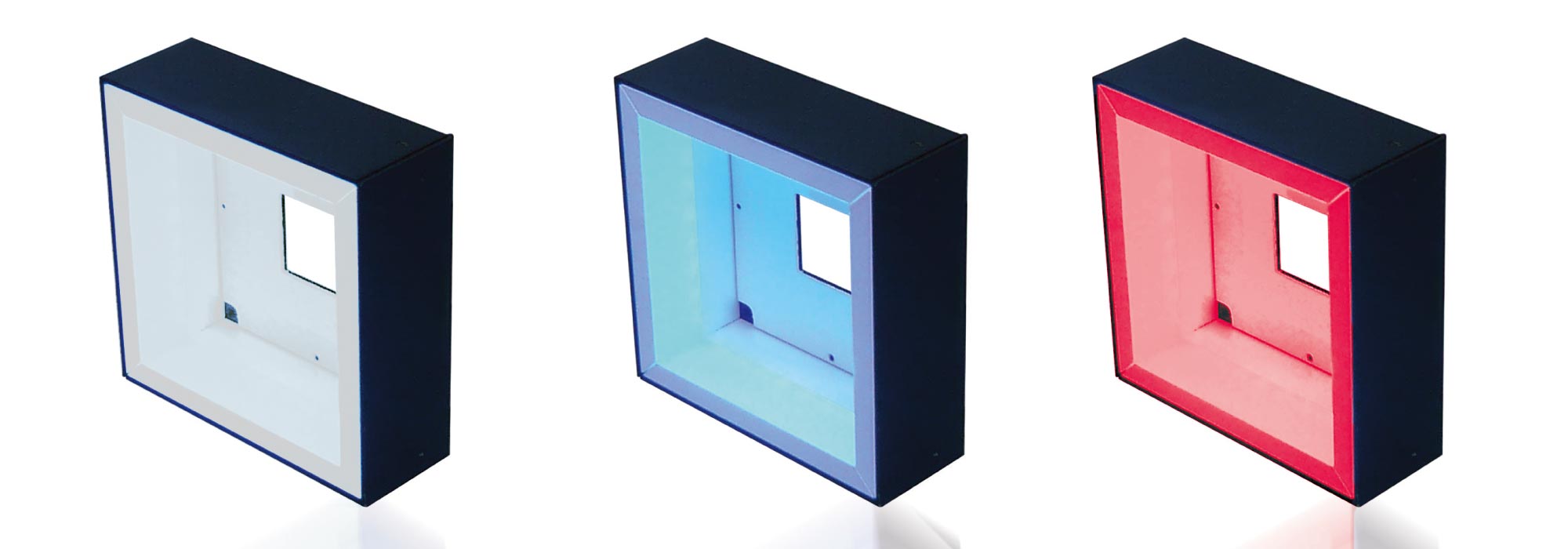

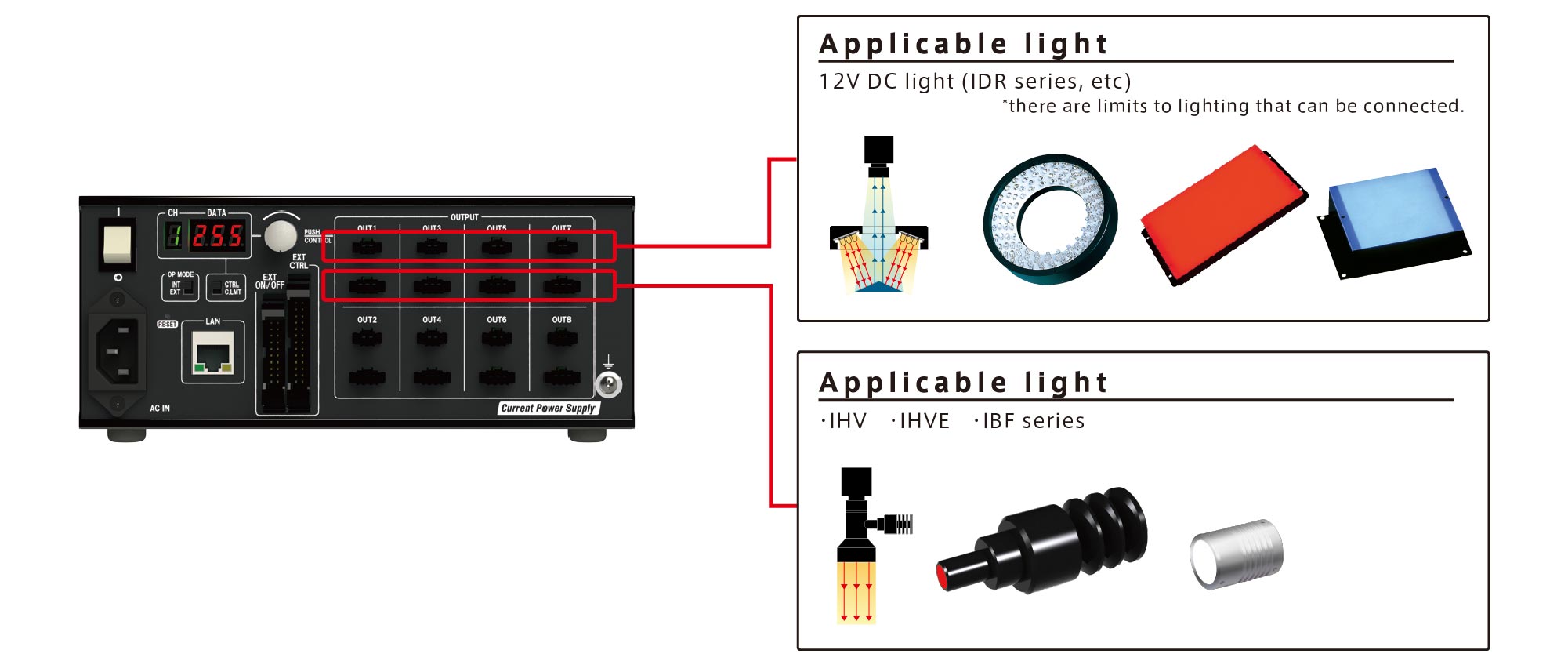

| IHV-20AIR-850 | 350mA | Coaxial Light | 850nm |

| IHV-20AIR-940 | 350mA | Coaxial Light | 940nm |

| IHVE-21AIR-850 | 700mA | Coaxial Light | 850nm |

| IHVE-21AIR-940 | 700mA | Coaxial Light | 940nm |

*Please consider the Infrared4 series.

What is infrared light?

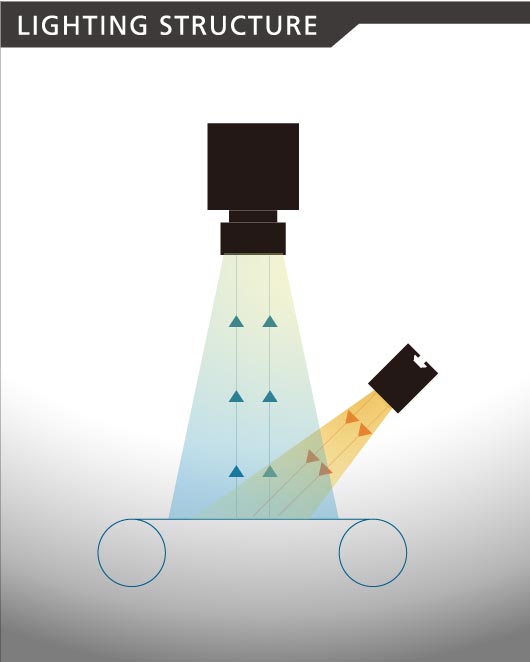

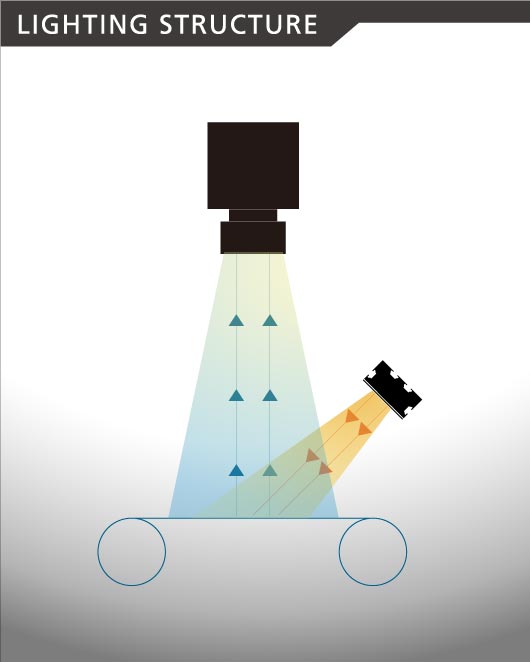

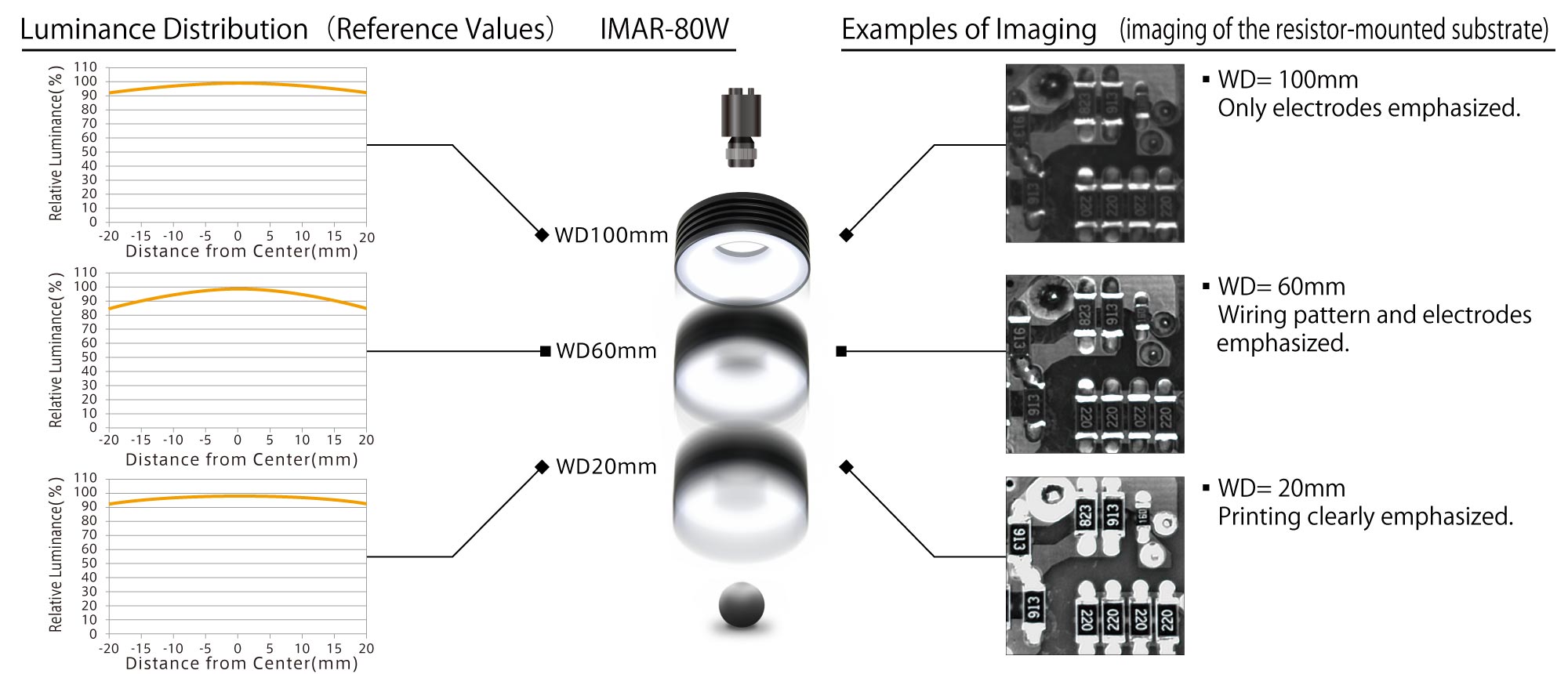

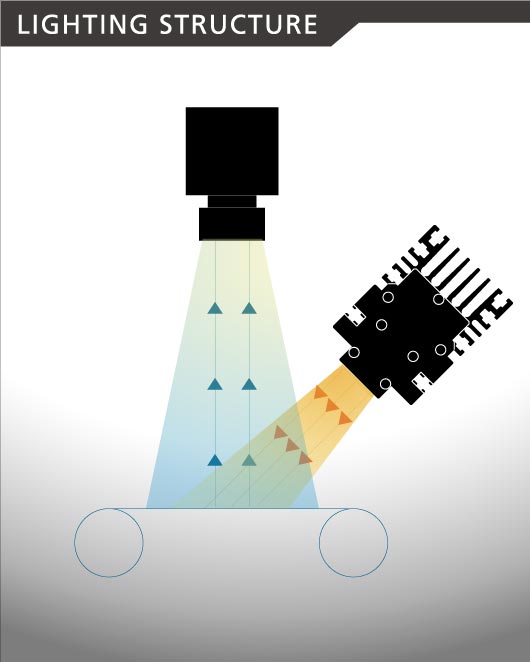

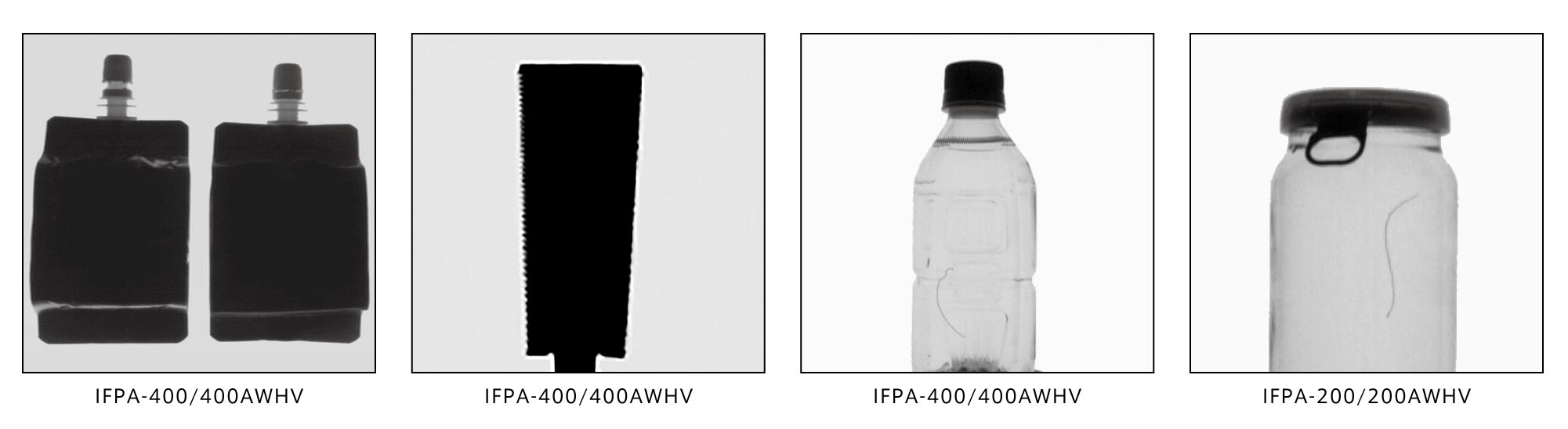

Here are some examples of foreign-object and dents inspection using infrared lighting.

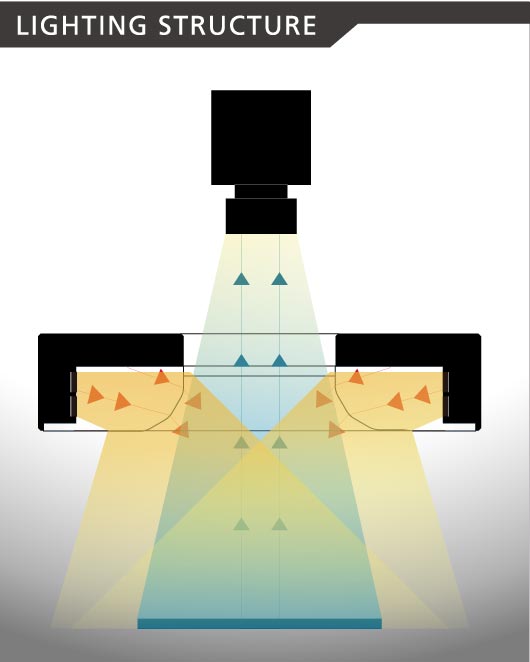

Infrared lighting has a longer wavelength than visible lighting and is not visible to the human eye.

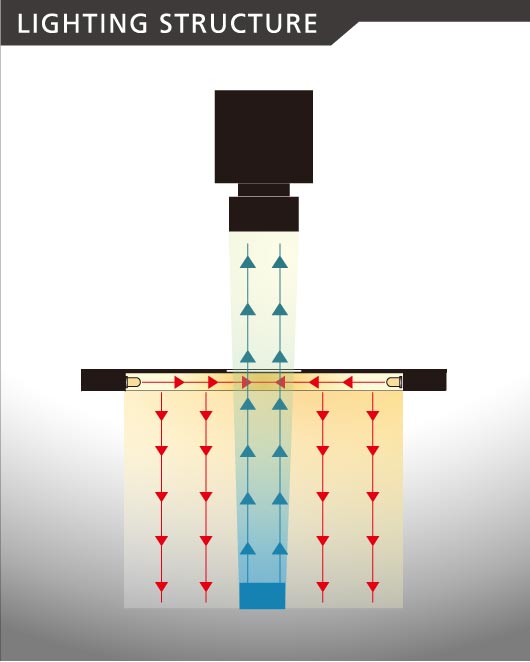

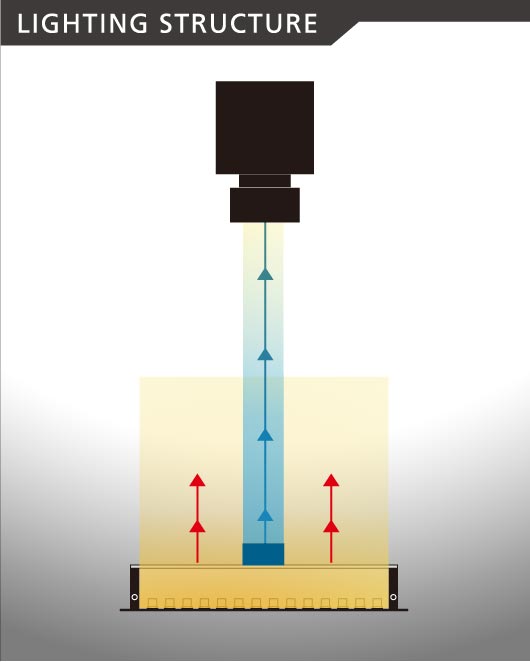

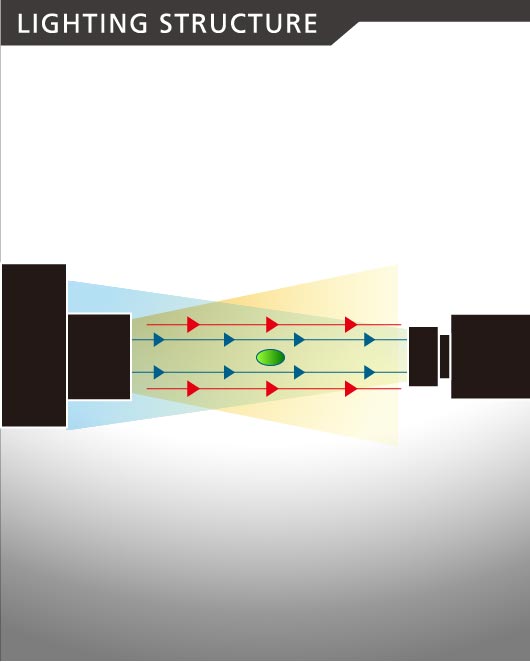

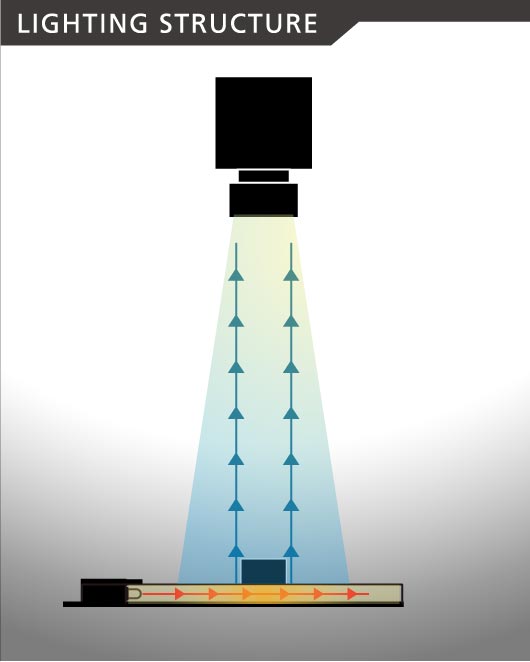

Because infrared light has a very low scattering rate compared with ultraviolet light and visible light, which means transmittance is high, it allows liquid and ink to be penetrated.

As the wavelength range is limited, it does not affect photosensitive object, unlike halogen.

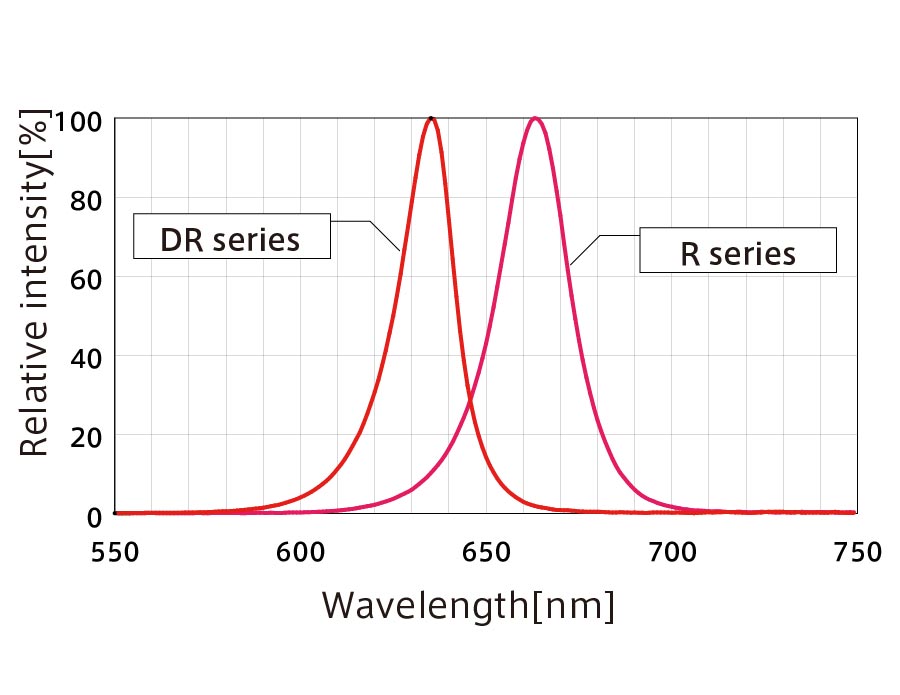

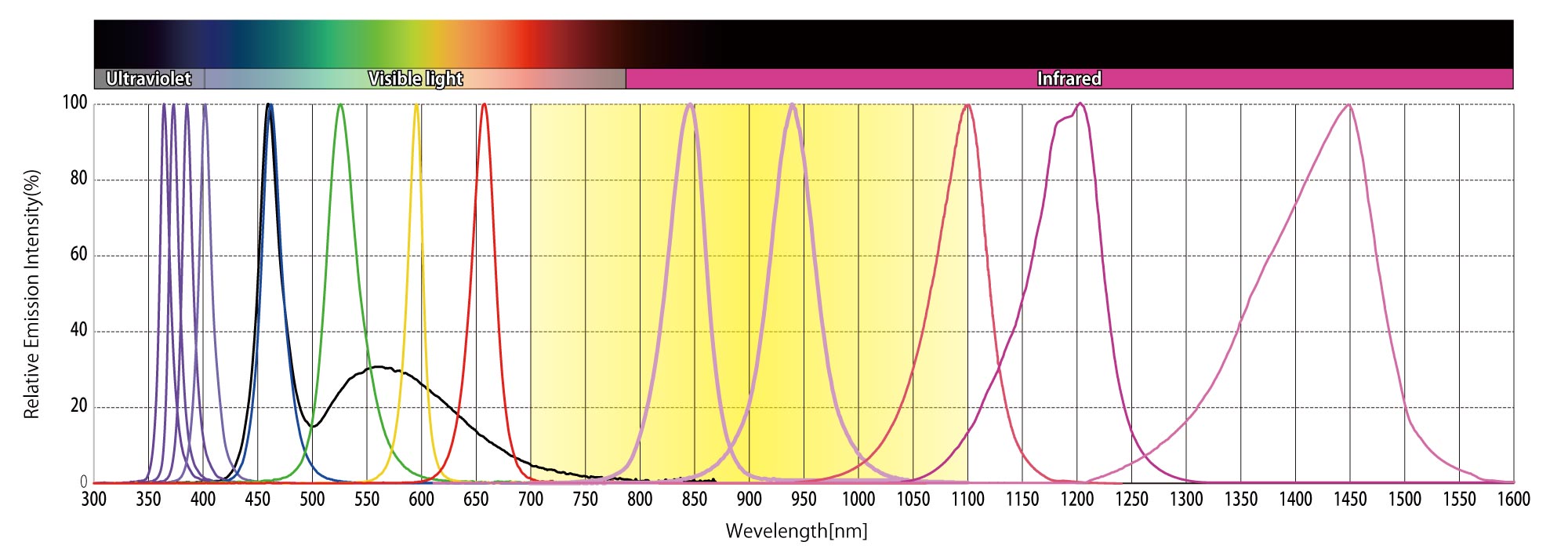

Infrared wavelength distribution graph

What is scattering rate?

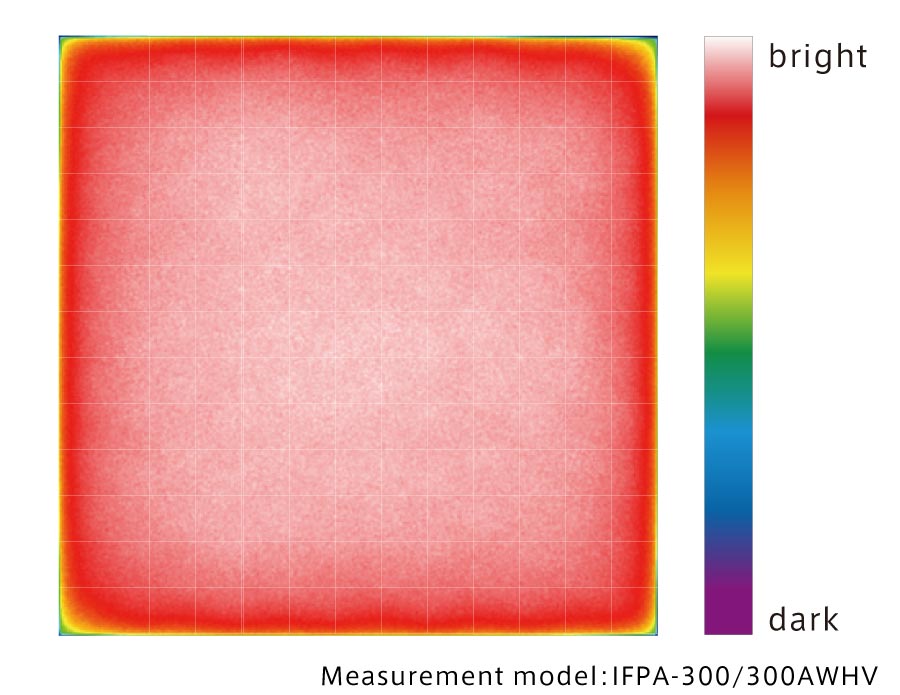

Scattering rate indicates how easy it is for light to change direction when light hits the surface of object.

The higher the scattering rate, the easier it is for light to scatter on hitting a surface, which means it is ideal for surface inspection. On the other hand, a lower scattering rate makes it easier to transmit through the surface of an object and, therefore, is ideal for transmission applications.

The longer the wavelength, the smaller the scattering rate, making it suitable for inspection applications as a backlight.

| Color | Peak Wavelength | Main inspection applications | Scattering Rate |

|---|---|---|---|

| White | Color processing, etc. | ||

| Ultraviolet | 365nm | Non-destructive inspection, etc. | Approx. ten time more |

| 375nm | Fine scratch inspection, etc. | Approx. nine time more | |

| 405nm | Approx. eight time more | ||

| Blue | 470nm | Scratch inspection, etc. | Approx. four time more |

| Green | 525nm | Visual inspection, etc. | Approx. two point five time more |

| Yellow | 590nm | Inspection in exposure environment, etc. | Approx. one point six time more |

| Red | 660nm | For backlighting, etc. | 1 |

| Infrared | 850nm | Transmission lighting | Approx. zero point four time more |

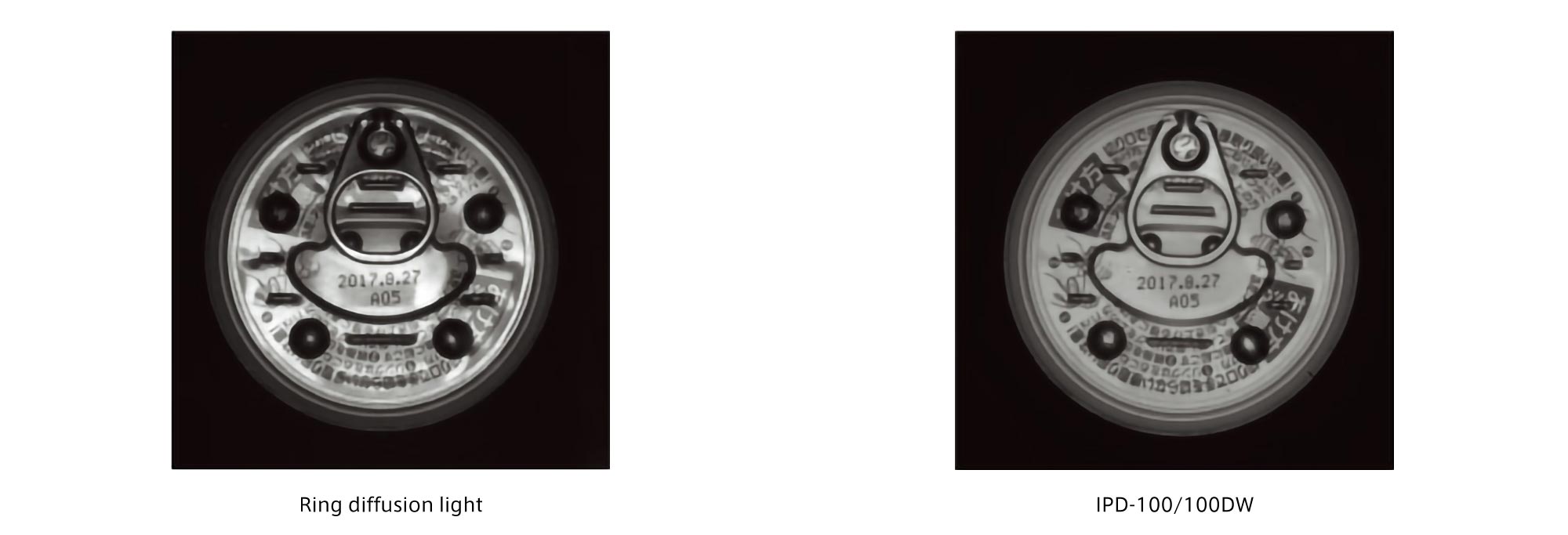

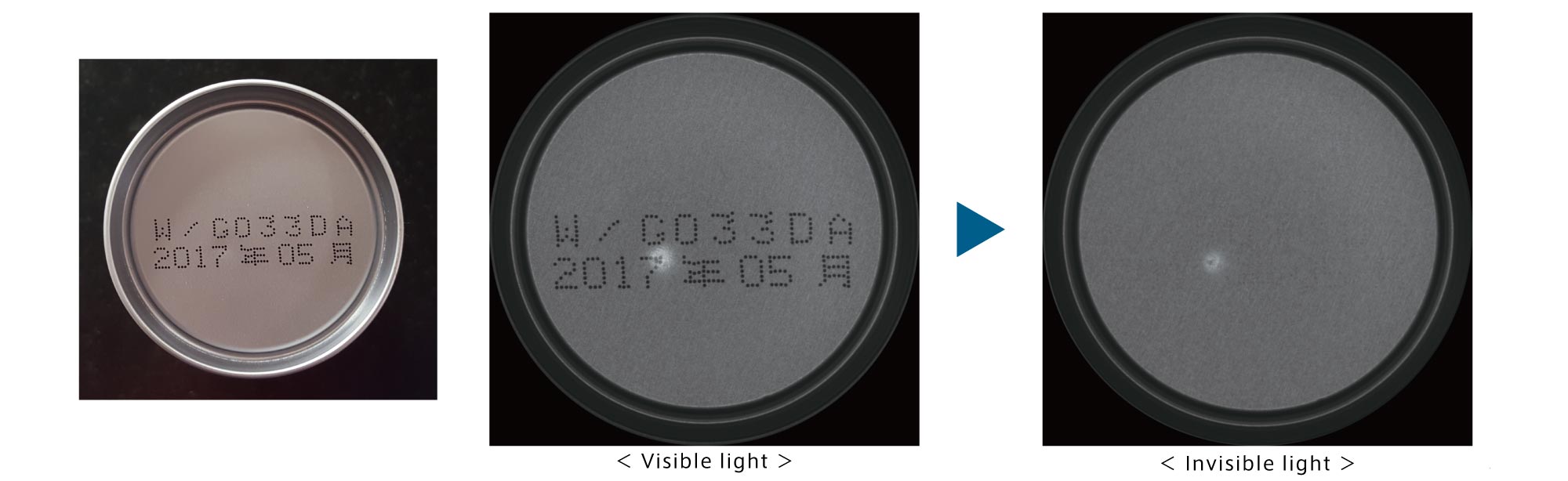

Sample: Dent inspection on the bottom of a can

It is difficult to detect dents that overlap with the print using visible lighting. As Infrared lighting can erase the print, only the dent can be detected.

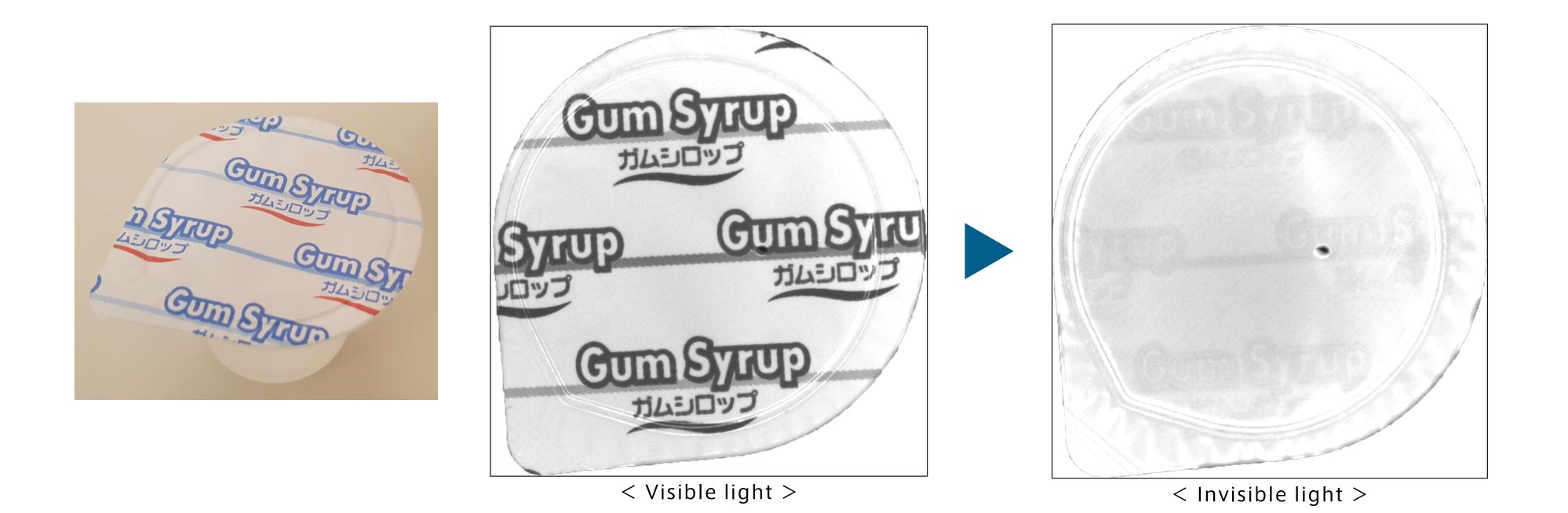

Sample: Pinhole inspection of plastic containers

Visible lighting makes it difficult to detect pinholes that overlap with the package design. Infrared lighting can erase the package design and easily detect pinholes.

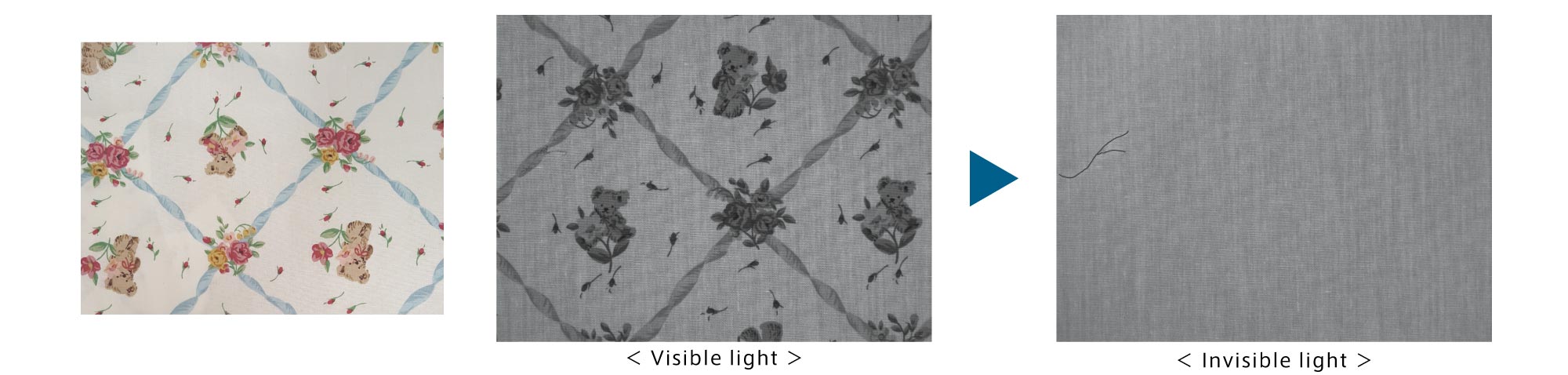

Sample: Cloth contamination inspection

The cloth pattern is imaged and contamination cannot be detected with visible lighting. Infrared lighting can erase the pattern and detect contamination.

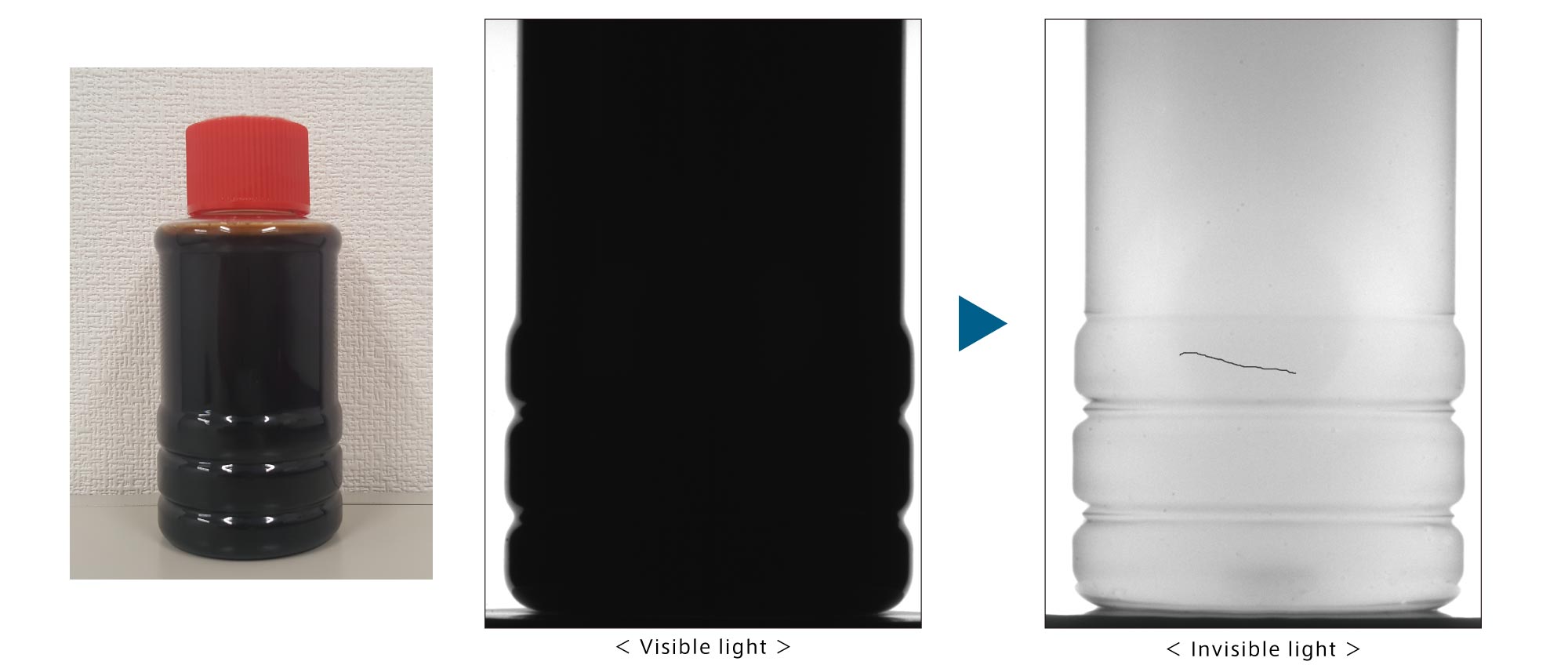

Sample: Inspection of liquid contamination

As visible lighting does not allow liquid to be permeated, contamination in the liquid cannot be detected. Infrared lighting allows liquid to be permeated and detects contamination in the liquid.

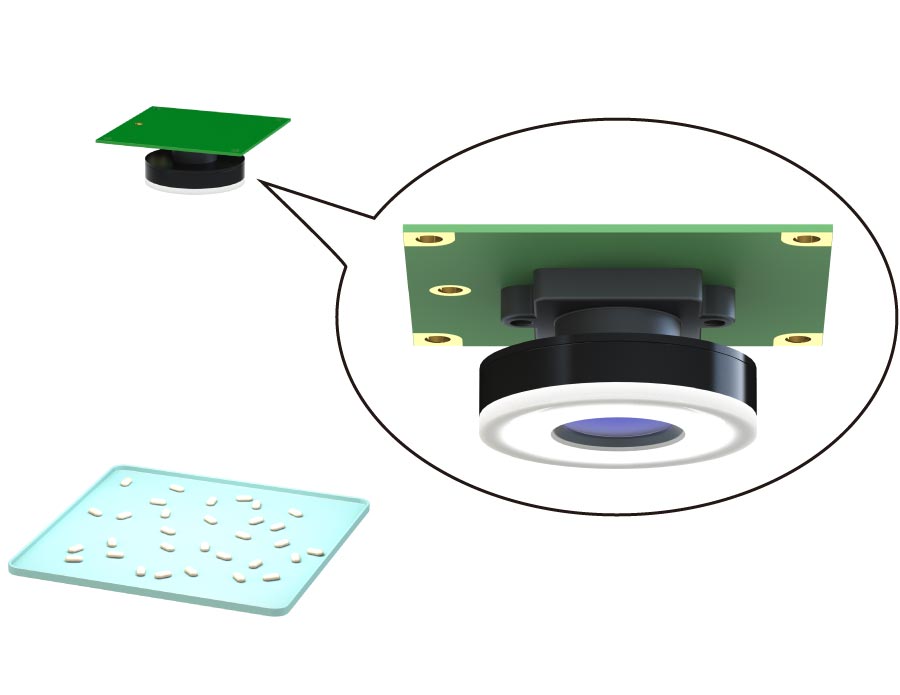

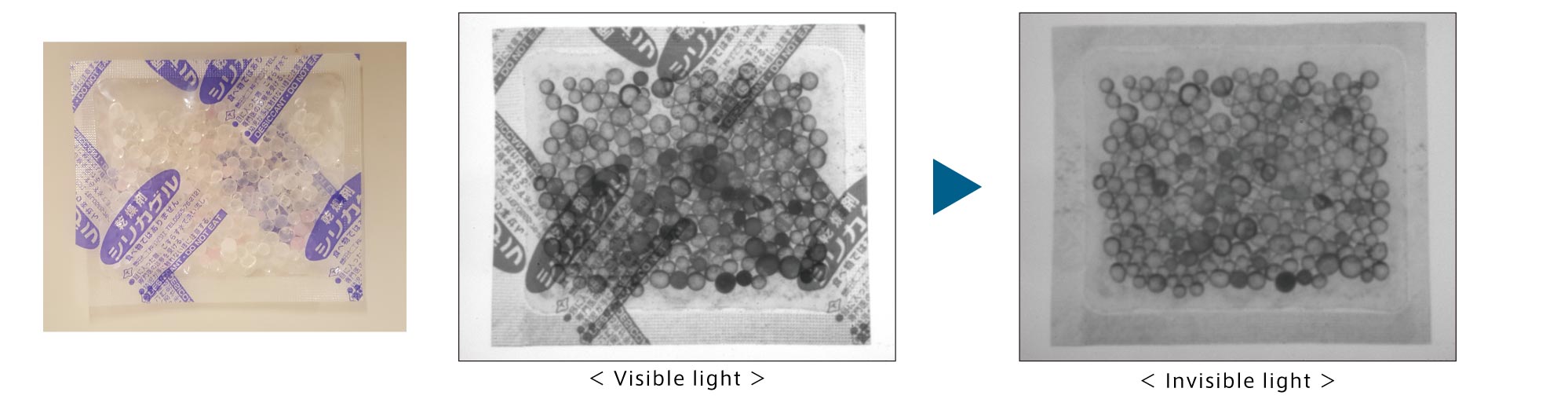

Sample: Inspection of package contents

As visible lighting cannot permeate the packaging design, the contents cannot be counted accurately. Infrared lighting allows the packaging design to be permeated, the contents can be accurately counted.